Your powder coated wheels represent a significant investment—both financially and aesthetically. That flawless, durable finish that caught your eye on the showroom floor can last for decades with proper care, but one wrong cleaning product can permanently etch, dull, or discolor the surface in seconds. After consulting with professional detailers, chemists, and countless hours of real-world testing, we’ve discovered that the difference between wheels that look brand-new for years and those that prematurely age comes down to understanding what you’re actually spraying on them. This comprehensive guide cuts through marketing hype and gives you the expert knowledge to choose the perfect wheel cleaner for your powder coated investment—without the risk of costly mistakes.

Unlike traditional painted surfaces, powder coating creates a chemical bond that requires specific maintenance protocols. The internet is flooded with conflicting advice, and product labels often hide more than they reveal. Whether you’re dealing with stubborn brake dust, winter road salt, or just routine maintenance, the principles outlined here will help you navigate the complex world of wheel care chemicals and preserve that showroom shine for the long haul.

Top 10 Powder Coated Wheel Cleaner

Detailed Product Reviews

1. Chemical Guys Signature Series Wheel Cleaner - Safe for Gloss Finishes, Chrome, Painted, Powder-Coated, and Clear-Coated Wheels - Removes Brake Dust and Road Grime - 16 oz

Overview:

The Chemical Guys Signature Series Wheel Cleaner delivers professional-grade performance in a consumer-friendly package. This 16-ounce foaming formula targets brake dust, road grime, and oxidation across all glossy wheel finishes. Designed for weekly maintenance, it works safely on chrome, painted, powder-coated, anodized, and clear-coated surfaces without causing streaking or damage.

What Makes It Stand Out:

The fast-acting foam clings aggressively to vertical surfaces, maximizing dwell time to dissolve contaminants before rinsing. Unlike many harsh cleaners, it safely cleans beyond just the wheel face—use it on barrels, center caps, lug nuts, and even suspension components. The versatility extends across the entire vehicle spectrum, from daily drivers to motorcycles and RVs.

Value for Money:

At $10.99 ($0.69 per ounce), it sits in the mid-range category. While not the cheapest option, the concentrated formula and reputable Chemical Guys branding justify the investment. It outperforms budget generic cleaners while remaining significantly less expensive than professional detailing products.

Strengths and Weaknesses:

Strengths include universal finish compatibility, excellent foaming action, and trusted brand reputation. The spray nozzle provides consistent coverage. Weaknesses include the relatively small 16-ounce size for frequent users, and heavily soiled wheels may require manual agitation with a brush for optimal results. The scent is chemical but not overpowering.

Bottom Line:

This is an excellent choice for car enthusiasts seeking a safe, effective weekly wheel maintenance solution. It balances performance, safety, and price, making it ideal for those who care about preserving their wheel finishes.

2. Meguiar’s Hot Rims Aluminum Wheel Cleaner, Deep Foaming Rim Cleaner Spray Formulated to Effectively Clean Uncoated Polished Aluminum, Anodized, and Powder-Coated Wheels, 24 Oz

Overview:

Meguiar’s Hot Rims Aluminum Wheel Cleaner specifically addresses the unique challenges of sensitive aluminum finishes. This 24-ounce gel formula penetrates deep into wheel crevices, delivering thorough cleaning for uncoated polished aluminum, anodized, and powder-coated wheels that traditional cleaners might damage.

What Makes It Stand Out:

The specialized formulation targets the exact needs of aftermarket aluminum wheels and visible brake components. Its clinging gel consistency provides extended dwell time, allowing the active ingredients to break down stubborn brake dust without harsh acids. This maximum-strength-yet-gentle approach is rare in dedicated aluminum cleaners.

Value for Money:

At $6.97 for 24 ounces ($0.29 per ounce), this represents exceptional value—one of the lowest price-per-ounce ratios in the category. You’re getting a specialized, brand-name product for less than many generic alternatives, making it a smart choice for budget-conscious enthusiasts with aluminum wheels.

Strengths and Weaknesses:

Strengths include the aluminum-specific safe formula, excellent gel cling, deep penetration, and outstanding price point. It’s powerful enough for heavy contamination yet gentle on delicate finishes. Weaknesses include limited versatility for non-aluminum wheels, and the spray pattern can be somewhat narrow. The formula works best when wheels are cool to the touch.

Bottom Line:

For owners of polished aluminum or anodized wheels, this is the best value proposition available. It offers targeted cleaning power at an unbeatable price, backed by Meguiar’s trusted reputation.

3. MAD Acid Heavy Duty Wheel Cleaner & Rim Cleaner - Safe on Chrome, Clear Coated Painted Surfaces, Glass, Plastic, And Most Wheel Finishes - Brake Dust, Rust, and Grime

Overview:

When standard cleaners fail, MAD Acid Heavy Duty Wheel Cleaner brings industrial-strength power to the consumer market. This acid-based formula aggressively attacks severe brake dust, rust, calcium deposits, and mineral buildup that accumulate over time. It’s designed for the dirtiest, most neglected wheels needing restoration rather than maintenance.

What Makes It Stand Out:

The acid formulation dissolves contaminants that alkaline cleaners simply can’t touch, particularly rust and hard water spots. It restores chrome and clear-coated wheels to near-original condition with minimal scrubbing. The spray-and-rinse application makes it surprisingly user-friendly for such a potent product.

Value for Money:

At $22.97 for 16 ounces ($1.44 per ounce), this is premium-priced. However, for severely neglected wheels, it can prevent costly replacement or professional refurbishment. It’s a specialist tool rather than a daily driver—expensive but invaluable when you need maximum cleaning power.

Strengths and Weaknesses:

Strengths include unparalleled cleaning power on heavy contamination, rust and water spot removal, and a satisfaction guarantee. It works fast, typically within 15-20 seconds. Weaknesses include the acid formula requiring careful handling, gloves, and adequate ventilation. It’s overkill for lightly soiled wheels and could potentially damage sensitive finishes if misused. The price prohibits regular use.

Bottom Line:

Reserve this for extreme cases—heavily neglected wheels, significant rust, or stubborn mineral deposits. It’s a professional-grade solution for DIYers facing their toughest wheel cleaning challenges.

4. Adam’s Polishes Wheel & Tire Cleaner 16oz - Professional All in One Car Wash Wheel Well Cleaning Spray for Car Detailing | Safe On Most Rim Finishes

Overview:

Adam’s Polishes Wheel & Tire Cleaner takes a comprehensive approach by tackling both wheels and tires in one formula. This 16-ounce alkaline-based cleaner dissolves brake dust on rims while simultaneously removing the brown, oxidized film that plagues tire sidewalls. It’s engineered for detailers who view wheel care as a complete system.

What Makes It Stand Out:

The dual-action capability sets it apart—few products address tire browning effectively while remaining safe on wheel finishes. It strips away old dressings, silicones, and wax buildup, preparing tires for fresh dressing that will adhere properly and last longer. The high-sudsing formula provides visual feedback during cleaning.

Value for Money:

At $11.99 ($0.75 per ounce), it’s priced slightly above average. However, the 2-in-1 functionality eliminates the need for separate tire cleaner, potentially saving money. For detailing enthusiasts who regularly dress their tires, the extended dressing life provides additional value.

Strengths and Weaknesses:

Strengths include comprehensive wheel and tire cleaning, safe on multiple finishes, effective browning removal, and Adam’s 110% satisfaction guarantee. The formula works quickly and rinses cleanly. Weaknesses include the higher price point and potential overkill for users only wanting wheel cleaning. The alkaline formula requires prompt rinsing on sensitive finishes.

Bottom Line:

Ideal for serious detailers seeking a one-step solution for both wheels and tires. It justifies its premium through dual functionality and professional results.

5. Black Magic 120228 Intense Foam Wheel & Tire Cleaner, High-Foaming Formula for Deep Cleaning, Removes Dirt, Grime & Brake Dust – Safe on All Wheels, 22 Fl Oz

Overview:

Black Magic Intense Foam Wheel & Tire Cleaner brings user-friendly innovation to routine wheel maintenance. This 22-ounce foam spray features a color-changing formula that visually indicates contaminant removal, making it accessible for casual car owners who want professional results without complexity.

What Makes It Stand Out:

The white-to-brown color transformation provides immediate visual feedback, confirming the product is working. The high-foaming action lifts contaminants without requiring aggressive scrubbing, while the cherry scent transforms a chore into a more pleasant experience. It’s safe across all wheel types, tires, and wheel wells.

Value for Money:

At $8.99 ($0.41 per ounce), it offers solid middle-ground pricing with a generous volume. The 22-ounce size provides more applications than standard 16-ounce competitors, and the no-scrub formula saves time and effort—valuable currency for busy users.

Strengths and Weaknesses:

Strengths include the innovative color-changing indicator, pleasant cherry fragrance, large size, universal safety, and ease of use. The foam clings well to surfaces. Weaknesses include the “no scrubbing required” claim being optimistic for heavily soiled wheels—light agitation often helps. The scent, while pleasant, is strong and may not suit sensitive users. Performance on severe brake dust lags behind dedicated heavy-duty cleaners.

Bottom Line:

Perfect for casual enthusiasts and weekend warriors who prioritize ease of use and visual confirmation. It’s an excellent maintenance cleaner that makes wheel care less intimidating.

6. Adam’s Polishes Wheel & Tire Cleaner Gallon - Professional All in One Tire & Wheel Car Wash Wheel Well Cleaning Spray for Car Detailing | Safe On Most Rim Finishes

Overview: Adam’s Polishes Wheel & Tire Cleaner arrives as a gallon-sized powerhouse targeting the grimiest parts of your vehicle. This professional-grade solution tackles brake dust, road grime, and tire browning in one comprehensive formula designed for enthusiasts who demand showroom results with every wash.

What Makes It Stand Out: The alkaline-concentrated solvent blend specifically attacks silicone and wax buildup that causes tire browning, while remaining safe on clear-coated, powder-coated, chrome, alloy, and painted wheels. The 110% satisfaction guarantee demonstrates exceptional manufacturer confidence, and the gallon volume provides serious longevity for frequent detailers who clean multiple vehicles regularly.

Value for Money: At $34.99 for 128 ounces ($0.27 per ounce), this represents significant savings compared to typical 16-32 oz bottles priced at $20-25. For anyone cleaning wheels bi-weekly or maintaining multiple vehicles, the bulk format eliminates constant repurchasing. Casual users may find the initial investment high, but cost-per-use makes it economical over time.

Strengths and Weaknesses: Strengths include impressive cleaning power on heavily soiled wheels, multi-surface safety, high-sudsing action, and the industry-leading guarantee. The generous volume ensures months of supply. Weaknesses involve the bulky container requiring storage space, potential waste for occasional users, and the alkaline formula needing thorough rinsing to prevent residue.

Bottom Line: This is a top-tier choice for dedicated detailers and multi-car households. The gallon size, proven effectiveness, and risk-free guarantee make it a smart long-term investment. Occasional cleaners should consider smaller alternatives, but serious enthusiasts won’t find better value.

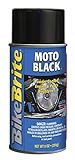

7. Bike Brite MC53000 Black Powder Coated Engine and Wheel Cleaner, 9 fl. oz.

Overview: Bike Brite MC53000 serves a hyper-specific niche: restoring black powder-coated motorcycle engine and wheel parts. This 9-ounce spray targets the unique challenges faced by Harley-Davidson and cruiser owners whose matte black finishes fade to gray from heat, oil, and road contaminants.

What Makes It Stand Out: Unlike general wheel cleaners, this formulation addresses powder coating’s porous nature, penetrating deeply to lift embedded grime without stripping the factory finish. It’s engineered specifically for inner primaries, primary covers, and accessories that standard cleaners either damage or inadequately clean, making it irreplaceable for its intended application.

Value for Money: At $12.99 for 9 ounces ($1.44/oz), this specialty product commands premium pricing. However, for motorcycle enthusiasts, preserving factory powder coating justifies the cost. Alternatives risk costly repainting, making this preventative maintenance. Casual riders may balk at the price, but dedicated owners understand its protective value.

Strengths and Weaknesses: Strengths include targeted formulation for black powder coating, ease of application, and ability to restore original luster without abrasives. The compact size suits motorcycle storage compartments. Weaknesses are limited versatility (not for chrome or polished surfaces), small volume requiring frequent repurchase, and niche application excluding car owners entirely.

Bottom Line: Essential for black powder-coated motorcycle owners seeking factory-fresh appearance. While pricey per ounce, it prevents far costlier finish damage. Car owners and those with mixed-finish bikes should look elsewhere, but for its intended audience, it’s irreplaceable.

8. Chemical Guys Signature Series Wheel Cleaner 32 oz Natural Citrus-Based Wheel & Tire Cleaner, Safe for Painted, Powder-Coated & Polished Finishes, Removes Brake Dust & Grime

Overview: Chemical Guys Signature Series leverages natural citrus extracts to deliver a biodegradable wheel and tire cleaning solution that balances power with environmental consciousness. This 32-ounce bottle positions itself as the eco-friendly alternative to harsh chemical cleaners while maintaining professional-grade performance.

What Makes It Stand Out: The highly concentrated citrus-based formula can be diluted for maintenance washes or used at full strength for deep decontamination, offering versatility competitors lack. Its safety across painted, polished, powder-coated, chrome, and wrapped wheels makes it a true all-in-one solution for detailers with diverse vehicle portfolios.

Value for Money: Priced at $24.94 for 32 ounces ($0.78/oz), it sits in the mid-range. The concentrate nature extends value—diluting 1:1 effectively doubles the volume for routine cleaning, dropping cost-per-use significantly. Compared to single-strength competitors, this flexibility provides superior long-term economics for regular users.

Strengths and Weaknesses: Strengths include natural citrus cleaning power, multi-surface safety, dilution flexibility, and effectiveness on embedded brake dust. It works on undercarriages and fender liners, adding versatility. Weaknesses involve slower action on heavy grime compared to alkaline cleaners, potential need for agitation on severe buildup, and citrus scent that some find overpowering.

Bottom Line: An excellent choice for environmentally conscious detailers seeking versatility. The dilution option and broad finish compatibility justify the price. While not the fastest on extreme grime, its balanced approach makes it ideal for regular maintenance and mixed-finish vehicle collections.

9. DURA-COATING TECHNOLOGY Wheely Clean - Professional Wheel Cleaner Spray - Ready-to-Use Tire Cleaner and Rim Cleaner - Suitable for Aluminum, Chrome, or Clear-Coated Wheels - Removes Brake Dust - 16 oz

Overview: DURA-COATING Wheely Clean emerges as a proudly American-made, ready-to-use wheel cleaner from a family-owned Florida business. This 16-ounce spray promises showroom sparkle through a straightforward application process designed for efficiency without mixing or measuring.

What Makes It Stand Out: Beyond wheels, this formula safely cleans glass and non-painted surfaces, demonstrating unusual versatility. The gloss enhancement feature leaves a noticeable shine beyond mere cleanliness, while the small-batch, shop-tested pedigree ensures professional-grade results backed by personal accountability you won’t find from corporate brands.

Value for Money: At $27.49 for 16 ounces ($1.72/oz), this positions as a premium product. While not cheap, the ready-to-use convenience and multi-surface capability offset the cost for users wanting one product for multiple tasks. However, dedicated wheel cleaners with larger volumes offer better per-ounce value for wheel-only use.

Strengths and Weaknesses: Strengths include American manufacturing, family-business quality control, gloss-enhancing properties, versatility across surfaces, and straightforward spray-scrub-rinse workflow. Weaknesses are high per-ounce cost, small volume requiring frequent replacement, and limited effectiveness on heavy iron deposits compared to dedicated iron removers.

Bottom Line: Ideal for buyers prioritizing American-made products and multi-surface convenience. While pricey, the quality and versatility justify the investment for moderate-use detailers. Heavy-duty enthusiasts should pair it with an iron remover, but as a maintenance cleaner, it delivers reliable performance with patriotic appeal.

10. Oberk 2-in-1 Wheel Cleaner & Iron Remover – pH Neutral Iron Decon Spray for Car Detailing – Safe on Painted, Chrome, Aluminum, Powder-Coated Wheels (2 in1 Wheel Cleaner 16 oz)

Overview: Oberk’s 2-in-1 Wheel Cleaner & Iron Remover merges iron decontamination with deep wheel cleaning in a single pH-neutral formula. This 16-ounce bottle targets embedded brake dust and iron particles through reactive chemistry that provides visual feedback as it dissolves contaminants.

What Makes It Stand Out: The color-changing reaction transforms from clear to purple as iron dissolves, offering satisfying confirmation of contamination removal. Clinging foam technology maximizes dwell time on vertical surfaces, while the pH-neutral composition ensures zero risk to anodized, polished, or delicate finishes that acidic cleaners might etch or discolor.

Value for Money: At $21.99 for 16 ounces ($1.37/oz), this 2-in-1 formula eliminates purchasing separate iron remover and wheel cleaner, potentially saving $30-40. For enthusiasts performing regular decontamination, this consolidation provides excellent value, though the foam texture means slightly faster consumption than thin liquids.

Strengths and Weaknesses: Strengths include dual-action chemistry, visual feedback, pH-neutral safety, cling foam effectiveness, and versatility on paint and glass. It delivers professional results without professional pricing. Weaknesses involve the 1-2 minute working time requiring prompt scrubbing, potential staining on porous surfaces if left too long, and moderate price point for budget-conscious buyers.

Bottom Line: A standout performer for serious detailers wanting iron removal and cleaning in one step. The color-change feature and pH-neutral safety make it superior to harsh alternatives. While not the cheapest, its dual functionality and finish-safe formula make it a smart, efficient choice for maintaining pristine wheels.

Understanding Powder Coated Wheels and Their Unique Cleaning Needs

Powder coating isn’t just another type of paint—it’s a thermoplastic or thermoset polymer finish applied electrostatically and cured under heat to create a skin that’s significantly tougher than conventional liquid paint. This process forms a molecular bond with the metal substrate, resulting in a finish that’s resistant to chipping, scratching, and fading. However, this same durability creates unique vulnerabilities when exposed to aggressive chemicals.

The microscopic structure of powder coating contains tiny pores that can trap contaminants, while the surface itself can be compromised by improper pH levels. Think of it like a non-stick pan: it’s incredibly durable when used correctly, but the wrong cleaning agent can destroy its properties permanently. Your wheels face a constant assault from brake dust (which contains metallic particles and carbon fibers), road salts, tar, and environmental pollutants that can embed themselves in these pores if not addressed properly.

What Makes Powder Coating Different?

The key difference lies in the curing process. Powder coating melts and flows at temperatures between 350-400°F, creating a uniform film that’s typically 2-3 times thicker than traditional automotive paint. This thickness provides excellent protection but also means chemical damage can penetrate deep before becoming visible. The cross-linked polymer structure is resistant to solvents but surprisingly vulnerable to strong acids and alkaline substances that can break down these molecular bonds.

Professional detailers often describe powder coating as “chemically sensitive but physically tough.” You can hit a curb and the coating might not chip, but spray the wrong wheel cleaner and leave it for 60 seconds, and you’ve created irreversible chemical etching. This dichotomy is why understanding cleaner chemistry isn’t just helpful—it’s essential.

Why Standard Wheel Cleaners Can Cause Damage

Most traditional wheel cleaners are designed for raw performance, not surface preservation. They rely on aggressive acids (like hydrofluoric or sulfuric acid) to dissolve brake dust rapidly, with pH levels dipping below 2.0—more acidic than lemon juice. While effective on bare metal or chrome, these formulations attack the resin binders in powder coating, causing microscopic pitting that accumulates over time.

The damage isn’t always immediate. You might use a harsh cleaner a dozen times before noticing the powder coat has lost its gloss or developed a chalky appearance. By then, the degradation has penetrated beyond the surface. It’s similar to sun damage on skin—cumulative and largely invisible until it’s severe.

The Chemistry Behind Safe Wheel Cleaning

Understanding what happens at the molecular level helps you make informed decisions. Safe wheel cleaning for powder coated surfaces is a balancing act between effective contaminant removal and surface preservation. The goal is to lift and suspend dirt rather than dissolve it through aggressive chemical reactions.

pH-Neutral Formulations: Your Safest Bet

pH-neutral cleaners (pH 6.5-7.5) work through mechanical action and surfactant technology rather than chemical aggression. They contain no free acids or caustic alkalis, instead using specialized molecules that surround and encapsulate dirt particles, allowing them to be rinsed away without attacking the coating itself.

These formulations typically take 2-3 minutes longer to work than acid-based cleaners, but that extra time is insurance against damage. Look for products that explicitly state “pH-neutral” rather than “pH-balanced”—the latter is often marketing fluff that can still mean pH 5.0 or 9.0, both dangerous for powder coating.

The Role of Surfactants and Chelating Agents

Quality wheel cleaners use advanced surfactants that reduce water’s surface tension, allowing it to penetrate the boundary layer between contaminant and coating. Chelating agents like EDTA or sodium gluconate bind to metal ions in brake dust, effectively “deactivating” them so they release from the surface without requiring acidic dissolution.

The best formulations combine multiple surfactant types—some for wetting, others for emulsifying oils, and specialized ones for suspending metallic particles. This multi-pronged approach cleans effectively at neutral pH levels. Think of it as a precision surgical team versus a sledgehammer approach.

Why Acid-Based Cleaners Are a Risky Gamble

Even “mild” acids like citric or oxalic acid can damage powder coating over time. These acids work by donating protons that break down iron oxide (rust), but those same protons can hydrolyze the ester bonds in polyester-based powder coats. The result is a surface that becomes increasingly porous, allowing future contamination to embed more easily.

What makes acids particularly dangerous is their concentration-dependent behavior. A product might be safe at 1% concentration but destructive at 5%. Since manufacturers rarely disclose exact concentrations, you’re playing Russian roulette with your wheels every time you use an acid-based cleaner.

Essential Features to Evaluate in Wheel Cleaners

When scanning product labels and marketing materials, focus on these non-negotiable features that separate wheel-safe formulas from wheel-destroying ones.

Non-Acidic and pH-Balanced Composition

Beyond just checking for “pH-neutral” claims, investigate the actual pH range. Reputable manufacturers will provide this data—look for pH 7.0 ± 0.5. Avoid any product that lists pH below 6.0 or above 8.0, even if marketed as “safe for all wheels.” The term “pH-balanced” without a specific number is meaningless marketing.

Also examine the ingredient list for hidden acids. “Citrus extract” sounds natural and safe but often refers to d-limonene solvents coupled with citric acid. “Natural cleaners” can be just as damaging as synthetic ones—poison ivy is natural too, but you wouldn’t rub it on your skin.

Iron and Brake Dust Dissolving Capabilities

Safe iron removal is possible without acids. Look for thioglycolic acid derivatives or ammonium thioglycolate—these compounds specifically target iron particles through a different chemical mechanism that doesn’t attack powder coating polymers. They often produce a color change (typically purple) as they react with iron, providing visual confirmation of activity.

The key is concentration. Effective iron removers for powder coating should work in 3-5 minutes, not 30 seconds. Rapid action usually indicates excessive chemical aggression. The color change should be gradual, not instant.

Gel vs. Spray Consistencies: Which Works Best?

Gel formulas cling to vertical surfaces better, providing extended dwell time without runoff. This is crucial for wheel faces and inner barrels where contaminants are heaviest. However, gels can be harder to rinse completely from crevices, potentially leaving residue.

Spray formulas offer better penetration into tight spaces and easier rinsing but require more frequent reapplication on heavily soiled areas. For powder coated wheels, a hybrid approach works best: spray for initial application and tight areas, gel for the main wheel face if dealing with heavy buildup. Many professional detailers decant their spray cleaners into foam sprayers to achieve the best of both worlds.

Color-Changing Technology: Hype or Helpful?

That dramatic purple or red color change when iron removers activate isn’t just marketing theater—it’s a useful diagnostic tool. The intensity of the color change indicates the concentration of iron contamination, helping you identify which wheels need more attention. However, the absence of color change doesn’t mean the product isn’t working; it simply means there’s minimal iron present.

Be wary of products where the color change happens instantly. This often indicates excessive chemical reactivity that can damage powder coating. The reaction should develop over 2-4 minutes, giving you time to agitate and monitor progress.

Ingredients That Will Destroy Your Powder Coating

Certain chemicals have no place on powder coated surfaces, regardless of dilution or contact time. Recognizing these on ingredient lists can save you thousands in wheel refinishing costs.

Hydrofluoric Acid: The Silent Killer

Often hidden under names like “HF acid,” “fluoride-based cleaner,” or “professional strength formula,” hydrofluoric acid is one of the few substances that can etch glass—and it will devastate powder coating. Even at concentrations below 1%, it penetrates the coating and attacks the metal substrate underneath, causing bubbling and delamination that appears months later.

The insidious nature of HF acid is that initial results look fantastic. It dissolves brake dust instantly, leaving wheels gleaming. The damage is cumulative and invisible until it’s catastrophic. If a product warns about using gloves and eye protection but doesn’t specify the active ingredient, assume HF acid is present.

Sodium Hydroxide: The pH Nightmare

Common in heavy-duty degreasers, sodium hydroxide (caustic soda) creates extremely high pH levels (12-14) that saponify oils and dissolve organic matter. On powder coating, it hydrolyzes the polymer bonds, essentially “melting” the surface at a microscopic level. The result is a permanently dulled finish that no amount of polishing can restore.

Sodium hydroxide is particularly damaging because it doesn’t rinse easily. It can remain active in microscopic pits and crevices, continuing to degrade the coating long after you’ve finished washing. Products marketed as “heavy-duty” or “industrial strength” almost always contain this ingredient.

Abrasive Compounds and Fillers

Some wheel cleaners contain fine abrasives to provide “scrubbing power” without brushing. These silica or aluminum oxide particles create micro-scratches in powder coating that accumulate over time, leading to a hazy appearance. Check for ingredients like “polishing agents,” “cleaning enhancers,” or unspecified “minerals.”

Even if a product claims to be “non-abrasive,” the presence of any particulate matter that doesn’t dissolve completely is suspect. True chemical cleaners should be completely liquid and leave no residue when dried.

Application Techniques for Professional Results

The best cleaner in the world won’t help if applied incorrectly. Professional results come from methodical processes, not just product selection.

The Two-Bucket Wheel Washing Method

Just as with paint care, wheels benefit from a two-bucket system: one with your diluted wheel cleaner, another with clean water for rinsing brushes. This prevents reintroducing dirt and brake dust onto the wheel surface. Use grit guards in both buckets to trap contaminants at the bottom.

Start with the wheel faces, then move to inner barrels, and finish with lug holes. This prevents cross-contamination and ensures you’re not dragging heavy grit across visible surfaces. Always use a separate wash media for each wheel to avoid transferring debris.

Brush Selection: Bristle Types Matter

Never use nylon or plastic bristles on powder coating—they create static electricity that attracts dust and can generate fine scratches. Opt for natural boar’s hair brushes for general cleaning and soft microfiber-covered brushes for delicate areas. The bristles should be long enough to flex, not stab.

For tight spots, use detailing swabs made from lint-free cotton or microfiber. Avoid metal tools entirely, even plastic-coated ones, as the coating can chip and expose sharp edges. Your brush investment should match your wheel investment.

Contact Time: The Golden Rule

The single biggest mistake enthusiasts make is not allowing adequate dwell time. Most safe wheel cleaners need 3-5 minutes to fully activate and suspend contaminants. Applying cleaner and immediately agitating is like brushing your teeth without toothpaste—it does little beyond moving dirt around.

Set a timer. Apply cleaner to one wheel, move to the opposite wheel, then return to the first. This ensures proper contact time without letting the product dry. If a cleaner dries on the surface, you’ve created a new problem—residue that’s harder to remove than the original brake dust.

Water Pressure: Finding the Sweet Spot

Too much pressure (over 2000 PSI) can force water past seals and into bearing packs, while too little leaves residue behind. For powder coated wheels, 1200-1500 PSI with a 40-degree nozzle provides optimal cleaning without risk. Hold the nozzle at least 12 inches from the surface.

If using a garden hose, employ a fireman’s nozzle rather than a standard spray head. The concentrated flow provides enough agitation to rinse effectively without requiring excessive volume. Always rinse from top to bottom, following gravity’s natural path.

Environmental Factors That Affect Cleaning

Your local climate and driving conditions should influence both your product choice and cleaning frequency. One-size-fits-all advice ignores these critical variables.

Winter Road Salt and Chemical Deicers

In cold climates, wheels face a triple threat: sodium chloride, magnesium chloride, and calcium chloride. These salts are hygroscopic, meaning they attract moisture and remain active even when dry. They penetrate microscopic pores in powder coating and create galvanic corrosion cells.

During winter, clean wheels weekly using a salt-specific neutralizer that contains corrosion inhibitors. These products use phosphate esters or amine-based compounds that bond to metal surfaces, displacing salt residues. Never let salt accumulate for more than a week—it becomes exponentially harder to remove.

Summer Heat and Baked-On Brake Dust

High temperatures polymerize brake dust onto wheel surfaces, creating a hard, resin-like bond. Summer cleaning requires longer dwell times (5-7 minutes) and possibly a second application. Work in the shade or during cooler morning hours—applying cleaner to hot wheels causes instant evaporation and product waste.

For track days or aggressive driving, consider a pre-cleaner application. Spray a light mist of wheel cleaner before driving hard; the heat will help it penetrate as brake dust forms, making post-drive cleaning dramatically easier.

Hard Water Stains and Mineral Deposits

If you have hard water (over 7 grains per gallon), you’re fighting a two-front war: cleaning the wheel and preventing water spots. The minerals in hard water—calcium and magnesium—can etch powder coating if left to dry, especially in hot sun.

Add a water softener to your final rinse, or use a spot-free rinse system that filters water through a deionizing resin. Alternatively, use a blower to dry wheels immediately after rinsing, eliminating the chance for mineral deposits to form. Never let hard water air-dry on powder coated surfaces.

Smart Shopping: Value vs. Price

The most expensive cleaner isn’t always the best, and budget options can be surprisingly effective if you know what to look for. Focus on cost-per-use rather than sticker price.

Concentrated Formulas: Maximum Economy

Professional-grade concentrates typically dilute 1:4 to 1:10 with water, bringing the per-ounce cost down to pennies. A $40 gallon of concentrate that makes 10 gallons of usable cleaner costs less per use than a $10 ready-to-use spray. The initial investment pays for itself after three months of regular use.

Concentrates also allow you to adjust strength based on contamination level. Light dust? Dilute 1:10. Heavy track day buildup? Use 1:4. This flexibility means you’re never over-using chemicals, which is better for both your wheels and the environment.

Ready-to-Use vs. Dilution Ratios

Ready-to-use products offer convenience but at a 300-500% markup. You’re paying for water and packaging. However, they eliminate mixing errors and are ideal for quick maintenance washes when time is limited. Keep a bottle of ready-to-use for weekly wipes and a concentrate for monthly deep cleans.

If you choose concentrates, invest in quality spray bottles with dilution markers. Using old chemical bottles risks cross-contamination, and eyeballing ratios leads to inconsistent results. Professional mixing bottles cost less than $5 and last for years.

Bulk Purchasing for Serious Enthusiasts

If you own multiple vehicles or detail for others, buying wheel cleaner by the 5-gallon pail reduces costs by 40-60%. Most professional formulas have a shelf life of 2-3 years unopened, so storage isn’t an issue. Split a pail with fellow enthusiasts to get bulk pricing without storage concerns.

Check with local detailers or car clubs—they often organize group buys from chemical distributors who won’t sell to individuals. This also gives you access to professional formulations not available in retail stores.

When to Seek Professional Help

Sometimes DIY isn’t the answer. Knowing when to call a professional can save your wheels from irreversible damage.

Recognizing Damage Before It Spreads

If you notice white, chalky residue that won’t rinse off, color fading in patches, or a rough texture developing, stop immediately. These are signs of chemical etching or clear coat failure. Continuing to clean with any product will worsen the damage. A professional can assess whether the coating can be refinished or needs complete stripping and reapplication.

Professional wheel restoration specialists use techniques like optical micrometers to measure coating thickness and pH testing strips to identify chemical residues embedded in the surface. This diagnostic approach is worth the $50-100 consultation fee compared to the $600-1200 cost of re-coating four wheels.

Professional-Grade Products for Home Use

Many products marketed to professionals are available to consumers through specialty suppliers. These formulations often contain higher concentrations of active ingredients and fewer fillers, providing better results with less product. They’re typically sold in larger containers and lack fancy labels, but the performance difference is noticeable.

Look for products with SDS (Safety Data Sheets) available online—these legally required documents list exact ingredients and concentrations, giving you transparency that consumer products avoid. A company willing to disclose this information stands behind their chemistry.

Critical Errors That Destroy Powder Coating

Even with the right product, technique errors can cause damage. These mistakes are so common that most enthusiasts have made at least one.

Over-Scrubbing and Aggressive Techniques

Powder coating doesn’t respond well to friction. Aggressive scrubbing creates micro-scratches that trap dirt, making future cleaning harder. The proper technique is to let the chemistry do the work: apply cleaner, allow dwell time, then use light pressure with a soft brush to agitate, not scrub.

If you find yourself pressing hard enough to bend bristles, your cleaner isn’t strong enough for the contamination level. Reapply and wait, don’t compensate with elbow grease. Powder coating should feel smooth as glass after cleaning—any roughness indicates surface damage.

Allowing Chemicals to Dry on Wheels

This is the fastest way to ruin powder coating. As water evaporates, chemical concentrations increase dramatically. A pH-neutral cleaner can become highly alkaline or acidic as it dries, etching the surface it was meant to protect. Always work in sections small enough to clean before drying begins.

In hot weather, pre-wet the wheels and work in the shade. If you must work in sun, apply cleaner to only one wheel at a time and keep it misted with water. The extra few minutes of prevention saves hours of correction later.

Cross-Contamination from Other Tools

Using the same wash mitt on paint and wheels is detailing heresy. Wheels harbor abrasive brake dust and metallic particles that will scratch your car’s paint. Conversely, paint care products can contain silicones or waxes that leave residue on wheels, interfering with brake performance and attracting dust.

Maintain completely separate tool sets: buckets, brushes, mitts, and drying towels. Color-code them (red for wheels, blue for paint) to prevent mix-ups. Store wheel cleaning tools away from paint care supplies to avoid accidental cross-contamination.

Becoming Your Own Product Tester

Don’t trust marketing claims—validate them yourself. Professional detailers test every new product before using it on customer vehicles, and you should too.

The 24-Hour Spot Test Protocol

Apply a small amount of cleaner to an inconspicuous area (inside the barrel or behind a spoke) and let it dwell for the maximum recommended time, then rinse. Wait 24 hours and inspect under bright light. Look for any change in gloss, texture, or color. Run your finger over the area—any roughness indicates etching.

For a more rigorous test, apply the cleaner to a cotton pad and place it on the test area, sealing it with plastic wrap. This creates a “worst-case scenario” of prolonged contact. If it passes this test, it’s safe for normal use. Document your tests with photos for future reference.

Decoding Marketing Jargon and Claims

“Safe for all wheels” means nothing—it’s not a legally defined term. “pH-balanced” without a specific number is equally meaningless. Look for specific claims: “pH 7.0,” “non-acidic,” “contains no hydrofluoric acid,” or “tested on powder coating.”

Be skeptical of products that claim to “dissolve brake dust on contact.” This usually indicates aggressive chemistry. Safe cleaners work through suspension and encapsulation, not dissolution. The best products often have boring, technical descriptions rather than flashy marketing.

Building a Maintenance Schedule

Consistency beats intensity. A structured maintenance program prevents contamination buildup that requires aggressive cleaning.

Weekly Quick-Clean Routines

Every week, rinse wheels with plain water and apply a diluted maintenance spray (1:20 ratio of your regular cleaner). Agitate lightly with a microfiber towel and rinse. This takes five minutes per wheel but prevents 90% of contamination buildup. Think of it as flossing for your wheels—brief but preventative.

Focus on the inner barrels during weekly cleans, as this area sees the most brake dust but gets neglected during regular washes. A quick spray and rinse here prevents the heavy buildup that requires aggressive monthly cleaning.

Monthly Deep-Clean Sessions

Once a month, perform a full decontamination: apply full-strength cleaner, allow full dwell time, brush all surfaces thoroughly, and consider using a clay bar designed for wheels to remove embedded particles. This is when you inspect for damage, apply protective products, and address any issues before they become serious.

Monthly sessions should include cleaning behind the wheels (the mounting surface) and checking for any signs of corrosion starting at lug holes. These areas are early warning systems for coating failure.

Seasonal Protection Applications

Every season change, apply a dedicated wheel sealant or ceramic coating designed for high-temperature brake environments. These products fill microscopic pores in the powder coating, creating a sacrificial barrier that makes cleaning easier and provides UV protection.

Fall application is critical before winter salt season, while spring application helps shed pollen and tree sap. These seasonal layers reduce chemical exposure and make your weekly maintenance dramatically more effective. A proper wheel coating can make brake dust rinse off with just water.

Frequently Asked Questions

Can I use dish soap to clean my powder coated wheels?

No—dish soap is designed to cut through grease using alkaline salts that can damage powder coating over time. It also strips any protective layers you’ve applied, leaving wheels vulnerable to contamination. Additionally, dish soap contains moisturizers and fragrances that leave residue, attracting more dirt. Always use a dedicated wheel cleaner formulated for automotive finishes.

How often should I clean my powder coated wheels to prevent damage?

Weekly light cleaning prevents the heavy buildup that requires aggressive chemicals. If you drive daily, a five-minute rinse and wipe weekly is sufficient. For vehicles driven occasionally or stored, monthly cleaning is adequate. The key is never letting brake dust accumulate for more than two weeks, as it becomes increasingly difficult to remove and can chemically bond to the coating.

What pH level is actually safe for powder coated wheels?

The safe range is pH 6.5 to 7.5—true neutral territory. Anything below pH 6.0 is acidic enough to etch over time, while anything above pH 8.0 is alkaline enough to degrade the polymer binders. Always verify with pH test strips if the manufacturer doesn’t specify. Even “mild” cleaners with pH 5.5 or 8.5 will cause cumulative damage.

Are iron removers safe, or will they stain my powder coating?

Properly formulated iron removers are safe and essential for thorough cleaning. Look for thioglycolate-based formulas, not acid-based ones. The color change (purple reaction) is normal and rinses completely. Problems occur when iron removers contain added acids to speed up reaction time. Always spot test and never let them dry on the surface.

How do I know if my wheel cleaner is already damaging the coating?

Early warning signs include: loss of gloss in patches, a chalky white residue that appears after cleaning, increased brake dust adhesion (wheels get dirtier faster), and a rough texture when you run your finger over the surface. If water stops beading on previously hydrophobic wheels, the protective clear coat may be compromised.

Can I make a DIY wheel cleaner with household ingredients?

We strongly advise against it. Household ingredients like vinegar (acetic acid), baking soda (abrasive), or lemon juice (citric acid) will damage powder coating. The concentrations are uncontrolled, and the pH is unpredictable. Commercial wheel cleaners cost pennies per use when diluted properly and are engineered for safety. DIY “savings” can cost you $1,200 in wheel refinishing.

What’s the best way to dry powder coated wheels after cleaning?

Use a dedicated blower (like a MetroVac Sidekick) to force water out of crevices without touching the surface. If using towels, employ plush microfiber drying towels that have never touched paint. Pat dry rather than wipe, and pay special attention to lug holes and behind spokes where water hides. Never let wheels air-dry, especially with hard water.

Should I wax or seal my powder coated wheels?

Absolutely. A quality wheel sealant or ceramic coating provides a sacrificial layer that makes cleaning easier and protects the powder coating from chemical and UV damage. Apply every 3-4 months on daily drivers, or twice yearly on garage queens. This is the most effective preventative measure you can take beyond proper cleaner selection.

Is steam cleaning safe for powder coated wheels?

Steam cleaning is excellent when done correctly—use a steam temperature under 250°F and keep the nozzle moving to avoid overheating any single spot. The combination of heat and pressure lifts contaminants without chemicals. However, improper technique can soften the powder coating or force moisture past seals. If you’re not experienced with steam, stick to chemical cleaners.

How long should a quality powder coating last with proper maintenance?

With correct cleaning and protection, powder coating can last 15-20 years on daily drivers and indefinitely on garage-kept vehicles. The coating itself doesn’t fail—what you see as “aging” is actually surface contamination, UV degradation, or chemical damage from improper cleaners. Proper maintenance preserves the original gloss and protection for the life of the wheel.