There’s something almost therapeutic about working polish into glass by hand—watching haze dissolve, water spots disappear, and clarity emerge like you’re wiping away the world’s distractions. In an era where dual-action polishers dominate the detailing conversation, hand application remains the quiet champion of precision, control, and accessibility. Whether you’re tackling a week’s worth of road grime or years of neglected windshield etching, the right glass polish and proper technique can transform your driving experience from foggy frustration to crystal-clear confidence.

But here’s the truth most product pages won’t tell you: not all hand-application glass polishes are created equal, and the difference between a streaky mess and showroom-worthy transparency lies in understanding what you’re actually buying. This guide cuts through the marketing noise, diving deep into the chemistry, application nuances, and critical features that separate professional-grade results from disappointing DIY attempts. We’re not here to regurgitate spec sheets—we’re here to equip you with the knowledge to choose wisely and polish like a seasoned pro.

Top 10 Hand Application Glass Polish

Detailed Product Reviews

1. E.J. Wheaton Glass Wax, Polishes and Protects Windows, Mirrors and Metal Surfaces, Dries Chalk White, Easy to Apply and to Remove, Made in USA

Overview: E.J. Wheaton Glass Wax offers a traditional approach to glass and metal care, delivering a protective coating that keeps surfaces cleaner for extended periods. This American-made formula applies as a dark pink liquid before drying to a distinctive chalk white finish, signaling it’s ready for buffing. Designed for windows, mirrors, and metal surfaces, it emphasizes ease of use over aggressive correction.

What Makes It Stand Out: The visual drying indicator sets this product apart—users know exactly when to buff without guessing. Its multi-surface versatility extends beyond glass to metal, making it a convenient all-in-one solution for household maintenance. The formulation remains easy to remove even after prolonged exposure or direct sunlight, eliminating the sticky, difficult-to-remove residue common with lesser waxes.

Value for Money: At $1.87 per fluid ounce, this wax sits in the mid-range category. It’s reasonably priced for a protective maintenance product but doesn’t compete with heavy-duty polishing compounds for scratch removal. Compared to basic glass cleaners that offer no lasting protection, it provides tangible long-term value through its protective barrier.

Strengths and Weaknesses: Strengths include foolproof application, forgiving nature, pleasant user experience, genuine surface protection, and domestic manufacturing. Weaknesses involve limited corrective power—it won’t remove etched water spots or scratches—and the color transformation might initially confuse new users. It’s a maintenance product, not a restoration solution.

Bottom Line: Ideal for homeowners seeking easy-to-apply protection rather than aggressive glass restoration. Choose this for routine maintenance and prolonged cleanliness, but look elsewhere for scratch removal.

2. Glass Polish 1.7oz (50ml) GP-PRO Glass Polishing Compound for Professional Polishing of All Glass Surfaces - 2.3 microns

Overview: This professional-grade cerium oxide polishing compound targets fine imperfections with surgical precision. The 2.3-micron particle size makes it ideal for the final polishing stage in multi-stage glass restoration processes. At 1.7 ounces, it’s a concentrated solution designed for spot treatments rather than large surface areas, removing hairline scratches, light haze, and surface stains.

What Makes It Stand Out: The optimized cerium oxide formula delivers results typically reserved for professional glass shops. Its ultra-fine 2.3-micron composition polishes without introducing new micro-scratches, making it the perfect finishing touch after coarser abrasives. The ready-to-use consistency eliminates mixing guesswork, ensuring predictable results every time.

Value for Money: At $7.07 per fluid ounce, this appears expensive but reflects its professional-grade concentration. The small 1.7oz container actually stretches surprisingly far when used correctly—tiny amounts yield significant results. For those already invested in a multi-stage polishing system, it’s a cost-effective alternative to professional service fees.

Strengths and Weaknesses: Strengths include exceptional finishing quality, professional formulation, effectiveness on laminated and tempered glass, and minimal material waste. Weaknesses are its niche application (final step only), small volume limiting large projects, and requirement for prior sanding stages. It’s not a standalone scratch remover for moderate damage.

Bottom Line: Perfect for dedicated DIY detailers who understand multi-stage polishing. Pair it with coarser abrasives for comprehensive restoration, but don’t expect it to remove deep scratches alone.

3. Gel-Gloss No Streek Glass Wax Polish, 8 Fluid Ounces

Overview: Gel-Gloss delivers a budget-friendly yet professional-grade solution for common glass maintenance issues. This 8-ounce wax polish specifically targets hard water spots while providing a protective shine. Its unique formulation allows application in direct sunlight—a rare capability among glass care products—making it practical for real-world conditions.

What Makes It Stand Out: The ability to work effectively in direct sunlight eliminates the common frustration of products drying too quickly or streaking when used outdoors. Its specialized formula aggressively attacks mineral deposits and water spots that plague bathroom fixtures and automotive glass. The true professional-grade performance at a consumer price point creates exceptional accessibility.

Value for Money: At $1.12 per fluid ounce, this represents the best per-ounce value in the category. The generous 8-ounce size handles multiple vehicles or extensive household glass without frequent repurchasing. For those battling persistent water spots, it delivers targeted performance that cheaper cleaners cannot match.

Strengths and Weaknesses: Strengths include unbeatable price-to-performance ratio, sunlight-friendly application, water spot specialization, protective properties, and domestic manufacturing. Weaknesses involve the unfortunate “No Streek” spelling error on packaging, which may concern quality-focused buyers, and limited scratch-removing capability. It’s more corrective than protective waxes but less aggressive than pure compounds.

Bottom Line: The smart choice for budget-conscious users dealing with water spots and routine maintenance. It outperforms its price point but won’t replace dedicated polishing compounds for serious defect removal.

4. GLASS POLISH Cerium Oxide High-Grade 8.8oz (250g) Professional Glass Polishing Powder – 85% Pure, Enhanced Performance with 3.5 Micron Particle Size

Overview: This high-grade cerium oxide powder offers serious glass restoration capabilities in an 8.8-ounce jar. With 85% total rare earth oxide content and 3.5-micron particles, it targets fine scratches, water spots, and haze through a customizable slurry application. The suspension-treated formula ensures consistent mixing and superior water solubility compared to untreated powders.

What Makes It Stand Out: The suspension treatment prevents settling and clumping, maintaining consistent polishing action throughout the job. Its high purity concentration means minimal material achieves maximum results—most users need only small amounts per project. The powder format allows custom consistency adjustments from thin slurry to thick paste, adapting to specific defect severity.

Value for Money: At $2.27 per ounce for professional-grade material, this jar delivers exceptional longevity. The 8.8-ounce quantity handles numerous projects, making it economical for frequent users. While requiring more skill than pre-mixed compounds, the cost-per-use dramatically undercuts professional restoration services.

Strengths and Weaknesses: Strengths include high purity, suspension stability, customizable application, rapid defect removal, and excellent economy for large projects. Weaknesses involve the learning curve for mixing proper ratios, the 3.5-micron size being slightly coarser than premium finishing compounds, and its limitation to fine, shallow scratches only. Users must honestly assess scratch depth before purchase.

Bottom Line: Best suited for experienced DIYers comfortable with mixing their own compounds. It offers professional-grade results and economy but demands more technical skill than ready-to-use alternatives.

5. Glass Polish (3’’) Glass Scratch Removal Kit for use with a Drill on All Glass Surfaces

Overview: This comprehensive kit transforms an ordinary electric drill into a professional glass polishing system. Designed for DIY users facing substantial damage like scratches, scuffs, graffiti etching, and acid damage, it includes everything needed for complete restoration. The system claims three-times-faster performance compared to manual methods, making it practical for significant repairs.

What Makes It Stand Out: Unlike compounds alone, this kit provides the mechanical advantage necessary for meaningful scratch removal. The drill-powered approach tackles deeper damage that hand polishing cannot touch. Its inclusion of abrasive materials for multiple stages, from grinding to final polishing, creates a true end-to-end solution. The step-by-step visual guide demystifies professional techniques for beginners.

Value for Money: At $39.97, the initial investment exceeds single compounds but pales compared to professional glass replacement or restoration services costing hundreds. For vehicles or homes with multiple damaged surfaces, it pays for itself on the first major project. The kit’s versatility across automotive, residential, and commercial glass maximizes return on investment.

Strengths and Weaknesses: Strengths include complete toolset, drill power efficiency, ability to remove serious etching and scratches, suitability for all glass types including tempered, and excellent instructional materials. Weaknesses involve requiring a variable-speed drill, higher upfront cost for those with minimal damage, and potential for user error without careful technique practice.

Bottom Line: The definitive choice for tackling substantial glass damage without professional help. Skip this for minor maintenance, but for deep scratches and etching, it’s the most complete DIY solution available.

6. GLASS POLISH DIY 3” Windshield Polishing Kit for Car Glass Restoration, Remove Wiper Blade Damage, Fine Scratches, Haziness, and Water Spots, Restore Glass Clarity and Shine - GP21005

Overview: The GLASS POLISH DIY 3" Windshield Polishing Kit is a specialized automotive glass restoration system designed to remove minor imperfections from windshields and car windows. This drill-powered kit targets wiper blade damage, fine scratches, haziness, and water spots that accumulate over time, compromising visibility and safety. The package includes a universal drill attachment and polishing components specifically formulated for automotive glass surfaces.

What Makes It Stand Out: Unlike manual polishing methods, this kit leverages your existing power drill for rapid, consistent results. The universal attachment ensures compatibility with most drills, transforming a common workshop tool into a professional-grade glass restoration device. The product explicitly focuses on fine scratches—those barely perceptible to a fingernail—which represents the most common type of windshield damage. The safety emphasis is notable; by restoring original glass clarity and smoothness, it directly addresses driving visibility concerns.

Value for Money: At $24.95, this kit offers substantial savings compared to professional glass restoration services that can cost $100-200. For car owners dealing with minor windshield imperfections, it’s a cost-effective alternative to replacement. The drill-powered approach significantly reduces labor time versus manual polishing, making it efficient for DIY enthusiasts. However, the limitation to fine scratches means it’s not a universal solution for all glass damage.

Strengths and Weaknesses: Strengths include drill integration for speed and consistency, targeted formulation for automotive glass, clear safety benefits, and comprehensive defect removal for minor imperfections. The universal attachment adds versatility. Weaknesses are the requirement of an electric drill (which not all users own), limitation to fine scratches only, and potential learning curve for drill speed control. Users with deep scratches will need alternative solutions.

Bottom Line: This kit is an excellent investment for car owners with minor windshield blemishes who own a drill. It delivers professional results at a fraction of the cost, prioritizing safety through improved visibility. Just ensure your scratches qualify as “fine” before purchasing.

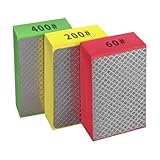

7. 4 Pack Diamond Hand Polishing Pads, Sanding Blocks Polishing, Sanding Pads Assortment, Sandpaper with High-Density Sponge, for Wood Tile Glass Stone Grinding (60#,100#,200#,400#)

Overview: This 4-pack of Diamond Hand Polishing Pads provides a versatile sanding solution for multiple materials including wood, tile, glass, and stone. The set includes four grit levels (60#, 100#, 200#, 400#) mounted on high-density sponge backing, offering both aggressive material removal and fine polishing capabilities in one affordable package. Each pad measures 3.7" x 2.2" for comfortable handheld use.

What Makes It Stand Out: The electroplated diamond construction delivers superior durability compared to traditional sandpaper, resisting tearing and cracking while maintaining consistent grit performance. The sponge backing efficiently stores water for wet polishing applications, enhancing efficiency and reducing dust. Clear grit markings eliminate confusion during multi-stage projects, allowing seamless progression from coarse grinding to fine polishing without hunting for the right pad.

Value for Money: At $8.99 for four professional-grade diamond pads, this set represents exceptional value. Traditional sandpaper wears quickly on hard surfaces like glass and stone, requiring frequent replacement. These diamond pads offer extended lifespan and versatility across multiple materials, effectively replacing numerous specialty tools. The ability to use them wet or dry further increases their utility, making them a cost-effective choice for DIYers and professionals alike.

Strengths and Weaknesses: Strengths include versatile grit assortment, durable diamond construction, wet/dry capability, clear grit identification, and wide material compatibility. The sponge backing provides excellent grip and water retention. Weaknesses include manual operation (slower than machine polishing), potential for uneven pressure application by inexperienced users, and the 60# grit may still be too fine for heavy material removal on very hard surfaces. The size might be small for large surface areas.

Bottom Line: This diamond pad set delivers outstanding versatility and durability at an unbeatable price. Perfect for DIY enthusiasts tackling small to medium projects across various materials, it outperforms traditional sandpaper while lasting significantly longer. A must-have for any multi-material workshop.

8. SZSYD 4Pcs Diamond Hand Polishing Pads for Sanding Ceramics Glass Tile Concrete Stone Marble Granite, 60#, 100#,200#,400# (Plane)

Overview: The SZSYD 4Pcs Diamond Hand Polishing Pads offer a comprehensive manual sanding solution for hard surfaces including ceramics, glass, tile, concrete, stone, marble, and granite. This set includes four progressive grits (60#, 100#, 200#, 400#) with foam backing for comfortable handheld operation. Each pad measures 3.6" x 2.4", providing adequate surface area for detail work and small to medium projects.

What Makes It Stand Out: The soft, lightweight foam backing distinguishes these pads, reducing hand fatigue during extended use while conforming to contoured surfaces. The complete grit progression from aggressive material removal (60#) to fine polishing (400#) handles most common refinishing tasks. The pads work effectively for both wet and dry applications, with wet polishing recommended for optimal results and dust control on delicate surfaces like glass and stone.

Value for Money: Priced at $14.99 ($3.75 per pad), this set sits in the mid-range for diamond hand pads. While more expensive than some alternatives, the quality foam backing and consistent performance across extremely hard materials justify the premium. For users primarily working with stone, tile, and glass, the durability and versatility eliminate the need for multiple specialized tools, offering long-term value despite higher initial cost.

Strengths and Weaknesses: Strengths include excellent foam comfort, complete grit progression, wide material compatibility, wet/dry flexibility, and clear grit recommendations. The pads excel at detail work and edge polishing. Weaknesses include manual labor requirements, slower progress on large surfaces, and the 60# grit may be insufficient for heavy grinding tasks. The price point is higher than basic options, and inexperienced users might apply uneven pressure.

Bottom Line: These SZSYD pads are ideal for detail-oriented projects on hard surfaces. The comfortable foam backing and comprehensive grit range make them perfect for stone and tile work. While pricier than basic options, the quality and versatility justify the investment for serious DIYers and professionals.

9. Glass Polish 14003 Glass Polishing Compound for Professional Polishing of All Glass Surfaces - 1.2 microns – 1.7 Oz

Overview: Glass Polish 14003 is a professional-grade cerium oxide polishing compound designed for the final stage of glass restoration. This 1.7-ounce container holds a ready-to-use white cerium oxide formula optimized for achieving optical clarity on all glass surfaces, including mirrors, laminated, and tempered glass. With a fine 1.2-micron particle size, it removes sanding marks, hairline scratches, and surface stains.

What Makes It Stand Out: The precisely optimized cerium oxide formula delivers professional optical polishing results that cheaper compounds cannot match. At 1.2 microns, it’s specifically engineered for the final polishing step in multi-stage scratch removal, creating a flawless, distortion-free finish. The compound works on all glass types, including the tempered and laminated safety glasses common in automotive and architectural applications, making it exceptionally versatile for professional use.

Value for Money: At $11.95 for 1.7 ounces ($7.07 per fluid ounce), this is a premium-priced compound. However, for professionals or serious DIYers undertaking glass restoration, the quality justifies the cost. A small amount goes a long way when used correctly, and achieving optically clear results without distortion is worth the premium over inferior products. For casual users with single small projects, the price may seem high relative to the quantity.

Strengths and Weaknesses: Strengths include professional-grade formulation, optimized 1.2-micron particle size, versatility across all glass types, excellent optical clarity results, and ready-to-use convenience. It’s essential for multi-stage scratch removal. Weaknesses include the high price per ounce, requirement for prior sanding stages (not a standalone solution), and the small container size may be insufficient for large projects. Beginners may need practice to achieve professional results.

Bottom Line: This is the go-to final polish for glass restoration professionals and serious DIY enthusiasts. While expensive, it delivers unmatched optical clarity when used as part of a complete scratch removal system. Worth every penny for achieving showroom-quality glass finishes.

10. EGOFIX 3pcs Diamond Hand Polishing Pads for Ceramic Tile Glass Grinding,Sanding Blocks Polishing 60#,200#,400#

Overview: The EGOFIX 3pcs Diamond Hand Polishing Pads provide a streamlined sanding solution for ceramics, glass, tile, and other hard materials. This set includes three grits (60#, 200#, 400#) designed for coarse grinding, medium detail work, and fine polishing. Measuring 92 x 57 x 31mm, these pads feature professional-grade diamond particles bonded to a high-hardness sponge backing for durability and flexibility.

What Makes It Stand Out: The set focuses on the most essential grits, eliminating the 100# pad to provide a more economical three-pad system that still covers most polishing needs. The high-strength diamond composition offers excellent wear and heat resistance, ensuring longevity even under heavy use. The company emphasizes after-sales service, providing customer support that many budget competitors lack, adding peace of mind for purchasers.

Value for Money: At $12.74 for three pads ($4.25 per pad), this set offers solid mid-range value. While missing the 100# intermediate grit, the included pads handle the critical coarse, medium, and fine stages effectively. The durable construction and reusable design provide better long-term value than disposable sandpaper. The after-sales service adds intangible value, particularly for users new to diamond polishing who may need guidance.

Strengths and Weaknesses: Strengths include durable diamond-sponge construction, good grit progression for most tasks, wet/dry versatility, absorbent sponge backing, and responsive customer service. The pads work well for deburring and edge work. Weaknesses include the absence of 100# grit (creating a larger jump between 60# and 200#), manual operation limitations, and the price per pad is higher than 4-pad sets. The three-pad system may be insufficient for projects requiring more gradual progression.

Bottom Line: EGOFIX delivers quality diamond pads with excellent customer support. The three-grit system is practical for most users, though professionals might miss the 100# intermediate stage. A reliable choice for DIYers who value durability and responsive service over having every possible grit.

Why Hand Application Still Matters in a Machine-Dominated World

The detailing world has gone power-hungry, with rotary and orbital polishers claiming supremacy over every surface. Yet hand polishing glass retains irreplaceable advantages that machines can’t replicate. You gain tactile feedback—feeling exactly how the abrasive bites into contamination or glides over clean glass. This feedback prevents the overheating and pressure inconsistencies that can warp lightweight modern windshields or damage sensitive integrated antennas and heating elements.

Hand application also offers surgical precision around complex curves, tight corners, and delicate trim that bulky machine pads can’t navigate. For enthusiasts without professional equipment budgets, it’s the most accessible entry point into true glass correction. Plus, there’s the matter of risk: a momentary lapse with a machine on glass can create irreversible swirls or even cracks, while hand polishing’s slower pace builds skill and minimizes catastrophic errors. The method rewards patience with results that often surpass rushed machine work.

Understanding Glass Polish Chemistry: What Makes It Work?

Glass polish isn’t magic—it’s a carefully engineered suspension of abrasives, lubricants, and carriers designed to mechanically level microscopic peaks and valleys on your windshield’s surface. Unlike chemical cleaners that dissolve contaminants, polishes physically abrade them away. The abrasive particles, typically aluminum oxide or cerium oxide, range from 1 to 10 microns in size, acting as ultra-fine sandpaper suspended in a creamy base.

The carrier lubricates this process, preventing the abrasive from scratching unnecessarily and giving you a workable window to massage the product. High-quality formulas use diminishing abrasives that break down into finer particles as you work them, creating a built-in finishing step. Cheaper polishes use non-diminishing abrasives that maintain their cut, requiring a separate finishing polish. Understanding this chemistry helps you match the product’s behavior to your specific glass condition rather than guessing based on bold label claims.

The Critical Difference Between Glass Polish and Glass Cleaner

This distinction trips up even experienced detailers. Glass cleaners are chemical solvents—ammonia, alcohol, or surfactant-based solutions that dissolve oils, fingerprints, and light dirt. They clean; they don’t correct. Polishes, conversely, are mechanical correction tools. If your glass suffers from water spot etching, wiper blade haze, or light surface scratches, no amount of chemical cleaner will restore it. You’re polishing a problem that needs abrasion.

Think of it like paint care: cleaner is your car wash soap; polish is your compound. Many enthusiasts waste hours and money layering increasingly aggressive cleaners when the issue is physical damage to the glass surface. The reverse is also true—polishing already clean but contaminated glass just grinds dirt deeper, creating more scratches. Your diagnostic process must start here: is the issue on the surface or in the surface?

Key Features to Look for in a Hand Application Glass Polish

When scanning labels and product descriptions, prioritize these non-negotiable features. First, abrasive quality and consistency: look for uniform particle size distribution. Inconsistent abrasives create unpredictable finishing and micro-scratching. Second, working time: you need at least 3-5 minutes of workable product before it flashes or dries, especially for hand application where speed is limited.

Third, residue behavior: premium polishes wipe off cleanly without oily films that cause streaking and attract dust. Fourth, compatibility: it must be safe for automotive glass, mirror coatings, and surrounding paint/trim. Fifth, clarity improvement metrics: vague “improves visibility” claims are meaningless; look for specific mentions of water spot removal, wiper haze elimination, or scratch refinement capabilities. Finally, consider concentration: a little should go a long way—diluteable or highly concentrated formulas offer better long-term value.

Abrasive Levels: Matching Polish Potency to Your Problem

Glass polishes fall into three distinct categories, and choosing wrong either wastes time or damages glass. Heavy-cut polishes contain larger abrasives (5-10 microns) designed for removing moderate scratches, heavy water spot etching, and years of neglected buildup. Use these sparingly and only when inspection confirms significant surface damage—they’re overkill for maintenance.

Medium-cut polishes (2-5 microns) represent the sweet spot for most enthusiasts, tackling light scratches, stubborn water spots, and the gray haze that accumulates from worn wiper blades. Finishing polishes (1-2 microns) refine glass after heavier cutting or maintain already-healthy glass by removing light contamination and oils. The key is honest assessment: run your fingernail across a water spot. If it catches, you need medium or heavy cut. If it’s smooth but visible, a finishing polish suffices.

The Role of Cerium Oxide in Professional-Grade Results

Cerium oxide isn’t just another abrasive—it’s the gold standard in glass polishing for good reason. This rare-earth mineral compound has a unique chemical affinity for glass, creating a polishing action that’s both mechanical and chemical. As it abrades, it chemically reacts with the silica in glass, producing a higher level of clarity and smoothness than aluminum oxide alone can achieve.

Professional-grade hand polishes typically contain high-purity cerium oxide, graded by color. White cerium oxide offers finer, more controlled cutting ideal for automotive glass where overheating is a concern. Pink or yellow variants are slightly more aggressive but still maintain that chemical polishing advantage. When you see cerium oxide on the ingredient list (or in marketing materials), you’re looking at a product engineered for true correction, not just cosmetic improvement. The concentration matters too—5-10% cerium oxide content indicates a serious formula.

Liquid vs. Paste Formulas: Which Is Right for Your Needs?

The viscosity debate isn’t just about preference—it directly impacts application efficiency and results. Liquid polishes spread effortlessly over large surfaces like windshields, requiring less initial pressure to work into the glass. They’re ideal for beginners because they reduce the risk of dry spots and inconsistent coverage. However, liquids can be over-applied easily, wasting product and creating messy run-off onto paint and trim.

Paste polishes offer concentrated power in a thicker base. You have superior control on vertical surfaces—no drips running down your windshield onto the dashboard. Pastes typically last longer per ounce and allow for more precise spot-treatment of specific defects. The downside? They require more elbow grease to spread evenly and can cake up if overworked. For hand application on automotive glass, pastes often win for their efficiency and control, but liquids excel when covering expansive SUV windshields or multiple vehicles.

The Importance of VOC Compliance and Environmental Safety

Volatile Organic Compounds (VOCs) aren’t just regulatory jargon—they’re health and performance factors. High-VOC polishes use harsh petroleum distillates that flash off quickly, reducing working time and filling your workspace with fumes. In regulated states like California, VOC limits are legally enforced, but even where they’re not, low-VOC formulas demonstrate a manufacturer’s commitment to modern chemistry.

Low-VOC polishes use water-based or soy-based carriers that stay workable longer and wipe off cleaner. They’re safer for you, your car’s interior (when polishing inside glass), and the environment. Check for “50-state compliant” or specific VOC content listed in grams per liter. Polishes exceeding 250 g/L often feel greasy, flash too fast, and leave stubborn residue that requires chemical glass cleaner to remove—defeating the purpose of your effort.

Evaluating Working Time and Buffing Ease

These two factors determine whether your polishing session ends in satisfaction or shoulder pain. Working time refers to how long the product remains wet and workable before drying to a haze. For hand application, you need at least 3 minutes of working time per section to fully break down diminishing abrasives. Premium formulas offer 5-7 minutes, allowing methodical cross-hatch patterns without racing the clock.

Buffing ease describes how effortlessly the residue wipes away. Some polishes dry to a dusty powder that buffs off with a feather-light touch. Others cure to a tacky, smeary film requiring aggressive buffing and multiple towel flips—exhausting work on a large windshield. Look for phrases like “easy wipe-off,” “dust-free finish,” or “minimal residue” in user reviews. The best polishes practically fall off the glass with minimal pressure, leaving behind pure clarity.

The Hidden Cost: How Much Product Do You Actually Need?

Sticker price deceives. A $20 bottle that covers two vehicles completely is cheaper than a $12 bottle that barely finishes one windshield. Calculate cost per square foot by estimating coverage. High-quality pastes often require only a pea-sized amount per 2’x2’ section—translating to 20+ windshields per 8oz jar. Liquids might need a quarter-sized dollop for the same area, yielding 10-12 windshields per bottle.

Consider concentration levels too. Some professional polishes arrive as concentrates you dilute 1:1 with water, effectively doubling your volume. Others market “ready-to-use” formulas that are secretly dilute. Check application instructions: if they recommend a “thin, even layer,” you’re looking at an efficient product. If they suggest “liberal application,” you’re buying more water than abrasive. For the average enthusiast polishing 2-3 times yearly, an 8oz paste or 16oz liquid should last 2-3 years.

Safety First: Protecting Your Car’s Trim and Paint

Glass polish doesn’t discriminate—it’ll abrade your paint, trim, and rubber seals with the same enthusiasm it shows your windshield. The number one rule is aggressive masking. Use 1-inch automotive masking tape to protect windshield trim, A-pillars, and the cowl area. For paste polishes, tape is non-negotiable since they don’t drip but will smear onto adjacent surfaces.

Run-off management is critical with liquids. Work in small sections and keep a clean microfiber towel tucked into the gap between glass and trim to catch drips immediately. If polish contacts painted surfaces, wipe it off instantly—don’t let it dry. For rubber seals, apply a thin layer of petroleum jelly before polishing as a barrier; it wipes away cleanly afterward. Remember: removing polish residue from textured black trim is nearly impossible without harsh chemicals that damage the trim further. Prevention takes two minutes; correction takes two hours.

The Application Arsenal: Tools That Make or Break Your Results

Your polish is only as good as the tool applying it. For hand application, foam applicator pads with a dense, closed-cell structure provide the most consistent pressure distribution. Avoid cheap, porous foam that absorbs polish instead of transferring it to glass. Look for pads 3-4 inches in diameter—large enough for efficiency but small enough for control.

Microfiber pads offer more cut for heavily contaminated glass but require careful technique to avoid uneven pressure. Felt pads provide maximum abrasion for scratch removal but demand perfection—any trapped debris creates new scratches. For buffing off residue, use edgeless, 300+ GSM microfiber towels in a two-towel system: one for initial removal, a second clean one for final buffing. Never reuse a contaminated towel. Invest in a pad cleaning brush to remove caked polish mid-job; dried abrasive clumps are scratch factories.

Step-by-Step: Mastering the Hand Polishing Technique

Success lives in the details. Step 1: Decontaminate—clay bar the glass thoroughly. Polishing over bonded contamination grinds it deeper. Step 2: Tape off all trim and paint edges. Step 3: Prime your pad with a small amount of polish, then add a pea-sized dab to the glass. Step 4: Work in 2’x2’ sections using overlapping cross-hatch patterns (vertical, then horizontal). Apply moderate pressure—enough to flex the pad slightly but not white-knuckle force.

Step 5: Monitor working time—when the polish turns from creamy to nearly transparent or develops a light haze, it’s time to stop. Step 6: Buff immediately with your first microfiber towel using light, straight motions. Step 7: Final buff with a clean towel, inspecting at multiple angles. Step 8: Repeat if defects persist. Pro tip: Work in shade on cool glass. Hot glass causes polish to flash instantly, reducing cutting power and creating stubborn residue. The entire windshield might take 45-60 minutes—rushing creates more problems.

Common Mistakes That Ruin Glass Polishing Efforts

Even quality products fail when technique falters. Mistake #1: Skipping the clay bar. That “haze” you’re polishing might be tree sap or industrial fallout that clay would remove in seconds. Mistake #2: Using too much product. Excess polish doesn’t increase cut—it increases residue and waste. A thin, even layer is always superior.

Mistake #3: Polishing in direct sunlight. The polish dries before abrasives break down, forcing you to use more pressure and creating uneven results. Mistake #4: Wrong pressure. Too light and you get no cut; too heavy and you create new micro-scratches. Find the sweet spot where the pad grips but glides. Mistake #5: Expecting miracles on deep scratches. If your fingernail catches deeply, you’re looking at glass replacement, not polishing. Knowing when to stop prevents glass thinning and optical distortion.

Maintaining Your Clarity: Post-Polish Protection Strategies

Polishing is correction, not preservation. Without protection, your pristine glass faces the same environmental assaults that damaged it originally. Apply a glass sealant or coating within 24 hours of polishing while the surface is surgically clean. These products form a hydrophobic barrier that repels water, dirt, and minerals, making future cleaning effortless and reducing the need for re-polishing.

For daily maintenance, switch to a silica-free glass cleaner—silica-based cleaners leave microscopic residue that builds into haze over time. Use a dedicated glass microfiber towel (different from your polishing towels) to prevent cross-contamination. In hard water areas, keep a spray bottle of distilled water and a squeegee in your car to immediately remove sprinkler water or bird droppings before they etch. With proper protection, a quality hand polish job can last 12-18 months before needing touch-ups.

Frequently Asked Questions

How often should I polish my car’s glass?

For most drivers, once every 12-18 months maintains optimal clarity. If you live in hard water areas or park under trees frequently, every 8-12 months may be necessary. Over-polishing thins glass over many years, so focus on prevention through sealants rather than frequent correction.

Can I use regular car polish on glass?

Absolutely not. Automotive paint polishes contain oils and fillers designed for clear coat, not silica-based glass. They’ll smear hopelessly, leave oily residue that attracts dust, and lack the hardness to cut glass effectively. Always use a dedicated glass-specific formula.

Will hand polishing remove deep scratches?

If you can feel the scratch with your fingernail catching significantly, hand polishing won’t remove it. You might reduce its visibility by 20-30%, but true removal requires professional machine polishing with specialized glass compounds or replacement. Hand polishing excels at light scratches and surface haze, not deep damage.

Is hand polishing safe for tinted windows?

Yes, but only on the exterior surface. Never polish the interior of tinted windows—the abrasive will destroy the film. For exterior polishing, modern quality tints are applied inside, so you’re safe. If you have an older car with external tint or aftermarket exterior films, test an inconspicuous spot first.

How do I know if I need a heavy or light abrasive polish?

Do the fingernail test: run your nail across water spots or scratches. If it catches, you need medium to heavy cut. If the glass feels smooth but looks hazy, a light finishing polish suffices. When in doubt, start with the least aggressive option and escalate only if needed.

Can I polish glass in direct sunlight?

Never. Hot glass causes polish to flash dry in 30-60 seconds, preventing abrasive breakdown and creating a cement-like residue that’s nearly impossible to buff off. Always work in shade on cool glass, ideally below 75°F ambient temperature.

What’s the difference between white and pink cerium oxide?

White cerium oxide is higher purity (99.9%) with finer particle consistency, ideal for automotive glass where heat control and optical clarity are paramount. Pink cerium oxide contains slightly more impurities and cuts marginally faster but risks micro-scratching if technique is imperfect. For hand application, white is the safer choice.

Do I need to clay my glass before polishing?

Yes, without exception. Claying removes bonded contaminants that polishing would simply grind into the surface, creating more scratches. It’s a 10-minute step that determines your success. Think of it as sanding wood—you always remove the nails and debris first.

Will polishing make my windshield more prone to chipping?

When done correctly, no. You’re removing less than 0.1 microns of surface material—insignificant compared to the 4-6mm thickness. However, over-polishing the same area 20+ times over years could theoretically thin it. The bigger risk is creating heat stress cracks from machine polishing, which hand application avoids.

How long should I wait after polishing to apply a sealant?

You can apply most glass sealants immediately after your final buff, provided you’ve removed all polish residue. The glass is clean and reactive, creating an ideal bonding surface. Some high-end coatings recommend waiting 30 minutes to ensure complete solvent evaporation, but this is rarely necessary for consumer-grade sealants.