Your paintwork battles daily assaults from UV rays, road grime, bird droppings, and industrial fallout. While traditional waxes have served enthusiasts for generations and ceramic coatings dominate professional circles, spray sealants have emerged as the sweet spot for modern car care—offering remarkable protection with minimal effort. These innovative formulations have democratized paint protection, putting professional-grade results within reach of weekend warriors and daily drivers alike.

Understanding what separates exceptional spray sealants from mediocre ones requires more than reading marketing claims. It demands knowledge of chemistry, application physics, and real-world performance metrics. Whether you’re protecting a garage-kept classic or a daily commuter facing harsh winters, the right spray sealant can maintain that just-detailed appearance for months, not weeks. Let’s explore everything you need to know to make an informed decision and achieve results that turn heads.

Top 10 Spray Sealants

Detailed Product Reviews

1. Gorilla Waterproof Patch & Seal Rubberized Sealant Spray, Crystal Clear, 14 Ounce (Pack of 1) - Seals Out Water, Air, and Moisture

Overview:

The Gorilla Waterproof Patch & Seal Spray delivers industrial-strength protection in a convenient aerosol can. This 14-ounce sealant creates a flexible rubberized coating that blocks water, air, and moisture penetration. Designed for serious repairs, it forms a self-leveling barrier that adheres to roofs, gutters, PVC pipes, and other common problem areas.

What Makes It Stand Out:

Unlike standard sealants, this formula offers exceptional temperature and UV resistance once cured, preventing degradation from sun exposure. Its paintable surface integrates seamlessly with both latex and oil-based paints (primer recommended for oil). The controlled spray nozzle ensures even application without messy drips, while the self-leveling properties automatically fill small gaps and cracks for a watertight seal.

Value for Money:

At $14.94 for 14 ounces, it positions itself as a premium repair solution. While pricier than craft sealers, it’s significantly cheaper than professional roofing repairs. Compared to Flex Seal, the Gorilla brand commands trust for heavy-duty applications, justifying the slight price premium for critical home maintenance tasks.

Strengths and Weaknesses:

Pros include superior UV/temperature resistance, excellent adhesion to multiple surfaces, self-leveling application, and paintability. Cons involve strong fumes requiring ventilation, longer curing times than advertised, and potential overkill for small craft projects. The rubberized finish may not suit aesthetic applications.

Bottom Line:

This is your go-to solution for serious waterproofing repairs around the home. Skip it for crafts, but for stopping leaks permanently, the Gorilla sealant’s durability and brand reliability make it worth every penny. Ideal for homeowners needing professional-grade results without contractor costs.

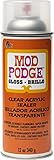

2. Mod Podge Spray Acrylic Sealer that is Specifically Formulated to Seal Craft Projects, Dries Crystal Clear is Non-Yellowing No-Run and Quick Drying, 12 ounce, Gloss

Overview:

Mod Podge’s Gloss Acrylic Sealer is a craft room staple that provides a protective, crystal-clear finish for artistic projects. This 12-ounce spray delivers a non-yellowing, quick-drying coating that enhances and preserves everything from decoupage to painted surfaces. Specifically formulated for creative applications, it offers reliable sealing without the heavy-duty rubberized texture of construction-grade products.

What Makes It Stand Out:

The trusted Mod Podge brand brings 50 years of formulation expertise to this sealer, ensuring it won’t yellow over time—a critical feature for preserving artwork. Its no-run formula allows for vertical application, while the easy cleanup process (simply spraying upside down to clear the nozzle) prevents frustrating clogs that plague cheaper alternatives.

Value for Money:

At $10.49 ($0.87 per ounce), it hits the sweet spot for crafters. While more expensive than Krylon’s Triple Thick, it offers specialized craft protection that generic sealers can’t match. For artists, the non-yellowing guarantee alone justifies the modest premium over basic acrylic sprays.

Strengths and Weaknesses:

Pros include the non-yellowing formula, glossy professional finish, trusted brand reputation, easy nozzle maintenance, and versatility across wood, metal, canvas, and terra cotta. Cons: not suitable for waterproofing leaks, lacks flexibility for outdoor structural repairs, and the gloss finish may be too reflective for some projects. Multiple thin coats are necessary for optimal protection.

Bottom Line:

Perfect for crafters and artists who need reliable, archival-quality sealing. Don’t confuse this with leak-stopping sealants—it’s for protecting creativity, not repairing roofs. For craft projects requiring a durable, beautiful finish, this American-made classic remains unbeatable.

3. Krylon I00500A07 12-Ounce Triple Thick Clear Glaze Aerosol Spray,High-Gloss

Overview:

Krylon’s Triple Thick Clear Glaze offers maximum impact with minimal effort, delivering a high-gloss finish that claims one coat equals three of conventional clear coatings. This 12-ounce aerosol provides a permanent, protective glaze ideal for polymer clay, bisque, plaster, and decorative crafts where a glass-like shine is desired.

What Makes It Stand Out:

The triple-thick formulation builds substantial depth in a single application, saving time and eliminating the wait between multiple coats. Its non-firing glaze chemistry makes it perfect for oven-cure polymer clays that can’t withstand traditional kiln temperatures. The high-gloss finish creates a professional, gallery-worthy appearance on decorative pieces.

Value for Money:

At just $6.47 ($0.54 per ounce), it’s the budget champion of this lineup. Crafters get premium build and gloss at nearly half the cost of Mod Podge. While it lacks the UV guarantees of pricier options, for indoor decorative projects, the value is exceptional—delivering three times the coating thickness per spray pass.

Strengths and Weaknesses:

Pros: incredible cost efficiency, rapid build and gloss, excellent for decorative crafts, works on heat-sensitive materials. Cons: not flexible or waterproof for outdoor use, lacks UV resistance for sun-exposed projects, can drip if over-applied, and strong solvent odor requires ventilation. Not suitable for functional repairs.

Bottom Line:

Grab this for decorative crafts demanding a deep, glassy finish. It’s not a replacement for flexible sealants or archival art protectors, but for sheer coating power per dollar, Krylon Triple Thick is unmatched. Best for indoor decorative projects where aesthetics trump durability.

4. Flex Seal, 14 oz, Clear, Stop Leaks Instantly, Transparent Waterproof Rubber Spray On Sealant Coating, Perfect for Gutters, Wood, RV, Campers, Roof Repair, Skylights, Windows, and More

Overview:

Flex Seal’s transparent rubberized coating promises instant leak stoppage with a flexible, waterproof barrier that adapts to various surfaces. This 14-ounce spray seeps into cracks and holes, drying to a watertight, pliable membrane that remains effective through temperature extremes. Marketed as a versatile solution, it bridges the gap between emergency repairs and creative projects.

What Makes It Stand Out:

The ability to apply on wet surfaces sets Flex Seal apart, making it invaluable for emergency leak repairs during storms. Its formulation withstands summer heat without sagging and winter cold without cracking, ensuring year-round reliability. The transparent finish allows underlying surfaces to remain visible while providing protection.

Value for Money:

Priced at $14.87 ($1.06 per fluid ounce), it’s positioned as a direct competitor to Gorilla’s sealant. While slightly cheaper, the per-ounce cost remains high compared to craft sealers. For emergency repairs, the price is justified by potentially saving thousands in water damage. However, for planned projects, traditional sealants may offer better value.

Strengths and Weaknesses:

Pros: works on wet surfaces, extreme temperature tolerance, flexible long-lasting coating, clear finish maintains aesthetics. Cons: strong odor requires excellent ventilation, messy application with overspray risk, higher cost per ounce than some alternatives, and can take 24-48 hours to fully cure. Not paintable like Gorilla.

Bottom Line:

Keep a can for emergency leak situations—its wet-surface application is a game-changer. For routine maintenance, compare with Gorilla based on specific needs. It’s less suited for crafts due to rubberized texture, but for quick, effective waterproofing, Flex Seal delivers on its promises.

5. Flex Seal, 14 oz, Black, Stop Leaks Instantly, Waterproof Rubber Spray On Sealant Coating, Perfect for Gutters, Wood, RV, Campers, Roof Repair, Skylights, Windows, and More

Overview:

Flex Seal’s black variant offers identical performance to its clear counterpart, providing a flexible, waterproof rubberized coating that stops leaks instantly. This 14-ounce spray delivers an opaque black finish that seeps into cracks and holes, creating a durable, temperature-resistant barrier for both functional repairs and creative applications where color matters.

What Makes It Stand Out:

The black formulation provides complete opacity in one application, making it ideal for hiding repairs on dark surfaces like black gutters, pipes, or automotive components. It maintains the same wet-surface application capability and extreme temperature resistance as the clear version, while offering a ready-to-use color that eliminates painting on compatible surfaces.

Value for Money:

At $14.87 for 14 ounces, the pricing matches the clear version, though the listed $0.53 per ounce appears miscalculated (actual cost is $1.06/ounce). The value proposition remains identical—premium pricing for emergency repair capability. For black surface repairs, it saves time and paint costs compared to using clear sealant plus topcoat.

Strengths and Weaknesses:

Pros: opaque coverage hides imperfections, same excellent temperature flexibility, works on wet surfaces, versatile for repairs and dark-themed crafts. Cons: black color unsuitable for light surfaces, same strong odor and ventilation needs, messy application, and long cure times. Limited aesthetic appeal for decorative projects.

Bottom Line:

Choose black Flex Seal when repairing dark surfaces or when you need opaque coverage without painting. Performance mirrors the clear version, so decide based on color requirements. For emergency repairs on black gutters, pipes, or automotive parts, this saves a painting step while delivering the same reliable waterproofing protection.

6. Leak Stopper Rubber Flexx – Waterproof Repair & Sealant Spray - Point & Spray to Seal Cracks, Holes, Leaks, Corrosion & More | Black – 1 Bottle 18oz

Overview: Leak Stopper Rubber Flexx is a versatile waterproof sealant designed for quick repairs across numerous surfaces. This 18-ounce black spray creates a flexible, rubberized coating that penetrates cracks and holes, drying to a watertight finish. Marketed for everything from roof shingles and gutters to arts and crafts projects, it promises durable protection against moisture and corrosion. The solvent-free formula claims UV resistance and long-term flexibility, making it suitable for year-round application in varying weather conditions.

What Makes It Stand Out: The standout feature is its versatility across wet or dry surfaces—a capability many competitors lack. The “point and spray” application eliminates the need for brushes or rollers, simplifying emergency repairs. Its temperature resilience is impressive, maintaining flexibility in summer heat without sagging and resisting cracks during winter freezes. The paintable semi-smooth finish allows for aesthetic integration, while the 18-ounce quantity provides ample coverage for multiple small projects or one substantial repair job.

Value for Money: At $11.28 ($0.63 per ounce), this product offers excellent value compared to premium brands like Flex Seal or Gorilla. The larger 18-ounce size means fewer purchases for ongoing projects, and its multi-surface capability reduces the need for specialized sealants. For DIY homeowners and hobbyists, it delivers professional-grade performance without the professional price tag, making it a cost-effective addition to any maintenance toolkit.

Strengths and Weaknesses: Strengths include easy aerosol application, wet-surface compatibility, UV resistance, paintable finish, and exceptional temperature tolerance. The generous quantity covers substantial areas. Weaknesses: black color limits aesthetic options for visible repairs, drying time can be slower in humid conditions, and overspray requires careful masking. The rubberized texture may not suit ultra-smooth finish requirements.

Bottom Line: Leak Stopper Rubber Flexx is a reliable, budget-friendly solution for emergency leak repairs and preventative maintenance. Its flexibility and surface versatility make it ideal for homeowners, RV owners, and DIY enthusiasts. While color options are limited, its performance and value justify keeping a can handy for unexpected repairs.

7. Loctite Tite Foam Big Gaps Spray Foam Sealant, 12 fl oz Can, 1 Pack - Polyurethane Expanding Insulation

Overview: Loctite Tite Foam Big Gaps is a high-density polyurethane foam sealant engineered to fill, seal, and insulate voids up to three inches wide. Unlike surface-coating sealants, this expanding foam penetrates deep into cavities, creating a durable, insulating barrier. Its professional-grade formulation adheres to wood, concrete, brick, stone, metal, and PVC, making it invaluable for remodeling, construction, and energy-efficiency improvements. The foam cures to a uniform cell structure that can be trimmed, sanded, and painted once hardened.

What Makes It Stand Out: The three-inch gap-filling capacity distinguishes it from standard caulks and sealants. Its high-density structure provides superior insulation value (R-value) while maintaining flexibility to accommodate building movement. The UV-resistant formulation prevents degradation in sun-exposed applications, and its exceptional adhesion eliminates the need for primers on most substrates. The controlled expansion reduces waste and minimizes the bulging common with lower-quality foams.

Value for Money: Priced at $7.98 for 12 ounces, this Loctite foam delivers professional performance at a consumer-friendly price point. While cheaper than contractor-grade two-part foam systems, it outperforms bargain brands in density and durability. The insulation properties can yield long-term energy savings, effectively paying for itself through reduced heating and cooling costs. For homeowners tackling air sealing projects, it offers an impressive return on investment.

Strengths and Weaknesses: Strengths include superior gap-filling capacity, excellent insulation properties, strong multi-material adhesion, UV resistance, and professional-grade durability. The foam remains flexible after curing. Weaknesses: expanding nature requires careful application to avoid overfilling, not suitable for surface-coating applications, must be painted for UV protection in exterior applications, and cleanup requires acetone before curing.

Bottom Line: Loctite Tite Foam Big Gaps is the go-to solution for insulating and sealing large voids. Its professional-quality formulation justifies choosing it over discount alternatives for critical air-sealing projects. While it demands careful application, the results deliver lasting energy efficiency and structural integrity.

8. Flex Seal MAX, 17 oz, 2-Pack, Clear, Stop Leaks Instantly, Waterproof Rubber Spray On Sealant Coating, Perfect for Gutters, Wood, RV, Campers, Roof Repair, Skylights, Windows, and More

Overview: Flex Seal MAX represents the brand’s super-sized offering in a clear formulation, delivering the same legendary leak-stopping performance in a more substantial package. This two-pack of 17-ounce cans creates a waterproof, flexible rubberized coating that seeps into cracks and holes, drying to a watertight seal. Designed for gutters, roofs, RVs, and windows, the clear finish allows for discreet repairs on visible surfaces. The formulation maintains pliability across temperature extremes, resisting summer sag and winter cracking.

What Makes It Stand Out: The clear color option is the primary differentiator, enabling invisible repairs on surfaces where black would be unsightly. The MAX sizing provides 17 ounces per can—substantially more than standard 14-ounce competitors. Flex Seal’s brand recognition and proven track record offers consumer confidence. The two-pack configuration ensures you have backup for larger projects or future touch-ups, eliminating mid-project supply runs.

Value for Money: While pricing wasn’t available at review time, Flex Seal products typically command a premium. The two-pack MAX configuration usually offers per-unit savings over single cans. Considering the brand’s reliability and the clear finish versatility, most users find the investment worthwhile for critical repairs. The larger can size reduces cost-per-ounce compared to standard versions, making it economical for extensive applications like RV roofs or gutter systems.

Strengths and Weaknesses: Strengths include trusted brand performance, clear finish for aesthetic repairs, excellent temperature resistance, multi-surface versatility, and generous quantity. The rubberized coating remains flexible for years. Weaknesses: premium pricing, potential for overspray requiring surface masking, strong solvent odor during application, and thicker consistency may require multiple coats for deep cracks.

Bottom Line: Flex Seal MAX Clear is worth the premium for projects requiring invisible waterproofing. The two-pack provides excellent value for RV owners, homeowners with visible gutter systems, and anyone prioritizing aesthetics alongside performance. While budget options exist, Flex Seal’s reliability justifies the investment for critical leak prevention.

9. Gorilla Waterproof Patch & Seal Rubberized Sealant Spray, Black, 16 Ounce (Pack of 1) - Seals Out Water, Air, and Moisture

Overview: Gorilla’s entry into the waterproof sealant market brings their “tough” reputation to aerosol form. This 16-ounce black spray creates a rubberized coating that seals out water, air, and moisture simultaneously. Engineered for roofs, gutters, skylights, flashing, chimneys, and PVC joints, it offers a self-leveling application that smooths over small gaps and cracks. The formulation provides temperature and UV resistance once cured, maintaining flexibility without cracking or peeling. Gorilla’s signature black finish delivers a professional appearance on most repair surfaces.

What Makes It Stand Out: The precision applicator nozzle provides superior spray control compared to competitors, delivering a clean, even coat with minimal overspray. The self-leveling property ensures seamless coverage over irregular surfaces, eliminating brush marks and texture inconsistencies. Gorilla’s reputation for extreme bonding strength extends to this sealant’s exceptional adhesion profile. The product’s ability to seal against air infiltration—not just water—adds value for energy-conscious users addressing drafts.

Value for Money: At $14.94 for 16 ounces ($0.93 per ounce), this is a premium-priced option. However, the controlled application reduces waste, and the multi-threat sealing capability (water, air, moisture) eliminates separate products. For critical repairs where failure isn’t an option—like roof leaks or RV damage—the Gorilla brand premium translates to peace of mind. The professional-grade results justify the cost for serious DIYers and contractors.

Strengths and Weaknesses: Strengths include precision application, self-leveling finish, excellent temperature/UV resistance, strong multi-surface adhesion, and comprehensive sealing against water, air, and moisture. The Gorilla brand ensures quality. Weaknesses: highest price per ounce in its class, black-only color option, strong initial odor, and requires careful surface prep for optimal adhesion. Not ideal for small craft projects due to cost.

Bottom Line: Gorilla Waterproof Patch & Seal is the premium choice for demanding applications where precision and reliability are paramount. Its superior applicator and self-leveling properties make it ideal for visible repairs requiring a flawless finish. While expensive, it’s a worthwhile investment for critical structural sealing and professional-grade results.

10. Aleene’s Spray Finish 6oz Acrylic Sealer, 6 Ounce (Pack of 1), Clear-Matte

Overview: Aleene’s Spray Finish provides a clear matte acrylic coating specifically formulated for crafting and hobby applications. This 6-ounce sealer protects indoor and outdoor projects with a subtle, non-glossy finish that won’t yellow over time. Unlike rubberized waterproofing sealants, this product focuses on preserving and finishing decorative items, artwork, and craft projects. The fast-drying formula sprays evenly across paper, wood, fabric, and other porous materials, creating a durable protective barrier against moisture and handling.

What Makes It Stand Out: The matte finish distinguishes it from glossy competitors, offering crafters a sophisticated, non-reflective surface that enhances rather than overwhelms their projects. Aleene’s decades-long reputation as “America’s Favorite Crafting Glue” brand instills confidence in archival-quality results. The non-yellowing formula ensures long-term clarity, critical for preserving artwork and photographs. Its compatibility with both indoor and outdoor projects provides versatility rare in craft-specific sealers.

Value for Money: At $6.97 for 6 ounces ($1.16 per ounce), the per-ounce cost exceeds heavy-duty sealants, but this reflects its specialized formulation. For crafters, the price is justified by the professional matte finish and archival properties. A single can covers numerous small projects, and the quality eliminates costly rework from yellowing or uneven application. Compared to artist-grade varnishes, it represents excellent value for hobbyists and DIY decorators.

Strengths and Weaknesses: Strengths include beautiful matte finish, non-yellowing archival quality, fast drying, even spray pattern, indoor/outdoor versatility, and trusted craft brand heritage. The clear coating preserves project appearance. Weaknesses: small quantity limits large-project use, not suitable for structural repairs or leak sealing, higher cost-per-ounce than utilitarian sealants, and requires multiple coats for heavy protection.

Bottom Line: Aleene’s Spray Finish is essential for crafters seeking professional-quality protection with a matte aesthetic. While not intended for home repairs, it excels at preserving and finishing creative projects. For its intended purpose, it delivers outstanding value and results that generic sealants cannot match. Keep this in your craft arsenal, not your toolbox.

What Are Spray Sealants and How Do They Work?

Spray sealants are synthetic polymer-based protective coatings delivered through a convenient aerosol or trigger-spray mechanism. Unlike paste waxes that rely on natural carnauba, these products create a molecular bond with your vehicle’s clear coat through synthetic ingredients like silicon dioxide (SiO2), polysiloxanes, or fluoropolymers. When you spray the product onto a surface, you’re deploying microscopic protective agents that cross-link and harden, forming a durable, transparent shield.

The science involves creating a low surface energy layer that contaminants struggle to adhere to. Think of it as applying an invisible, non-stick coating to your paintwork. This barrier doesn’t just sit on top; many modern formulations chemically bond at a molecular level, providing protection that withstands multiple washes and environmental exposure. The spray delivery system ensures even distribution without the heavy buffing required by traditional products, reducing the risk of marring delicate paint finishes.

The Evolution of Spray Sealants in Car Care

The journey from rudimentary spray waxes to today’s sophisticated sealants represents a revolution in convenience and performance. Early iterations from the 1990s offered minimal durability—often lasting just days—and provided little more than a temporary gloss boost. They were essentially quick detailers with marginal protective qualities, and discerning enthusiasts largely dismissed them as gimmicks.

Fast-forward to today, and the landscape has transformed dramatically. Advances in nanotechnology and polymer chemistry have birthed formulations that rival the longevity of some paint sealants applied by machine. Modern spray sealants now incorporate ceramic-infused technology, offering 3-6 months of real-world protection in some cases. This evolution reflects a broader shift in car care: consumers demand professional results without professional time investments. The market has responded with products that bridge the gap between spray convenience and serious protection.

Key Benefits of Choosing Spray Sealants

The primary advantage lies in their unparalleled ease of application. You can effectively protect an entire vehicle in 15-30 minutes, compared to the 1-2 hours required for traditional sealant application. This time efficiency doesn’t come at the cost of results—quality spray sealants deliver impressive gloss, slickness, and water behavior that satisfies even picky enthusiasts.

Versatility represents another significant benefit. These products work beautifully on paint, glass, wheels, trim, and even chrome, creating a unified protection strategy across your entire vehicle. The learning curve is virtually non-existent; unlike ceramic coatings that demand meticulous surface preparation and precise application to avoid high spots, spray sealants are forgiving and user-friendly. They also serve as excellent maintenance toppers for existing ceramic coatings or traditional sealants, extending overall protection schemes.

Spray Sealants vs. Traditional Wax: A Modern Comparison

While carnauba waxes offer unmatched warmth and depth on dark colors, they simply can’t compete with the durability and protective qualities of modern spray sealants. A premium wax might survive 4-6 weeks under ideal conditions, whereas a quality spray sealant routinely delivers 3-4 months of protection. The synthetic nature of sealants provides superior resistance to detergents, environmental pollutants, and UV degradation.

Application differences are stark. Wax application requires multiple steps: applying, allowing to haze, and buffing off—often with significant elbow grease. Spray sealants typically involve a simple spray-and-wipe protocol, with some “wet” formulas requiring no cure time. However, traditional waxes still hold a slight edge in pure gloss characteristics on certain paint colors. The choice often comes down to priorities: show-winning depth versus practical, long-lasting protection with minimal maintenance.

Spray Sealants vs. Ceramic Coatings: Understanding the Gap

Ceramic coatings represent the pinnacle of paint protection, offering 2-5 years of durability and extreme hardness. However, they demand professional application costs ranging from $500 to $2,000+ and require paint correction beforehand. Spray sealants operate in a different category—think of them as the accessible, user-friendly cousin that provides 70-80% of the benefits at 10% of the cost and 5% of the complexity.

The performance gap narrows when considering maintenance. A ceramic-coated vehicle benefits enormously from regular spray sealant applications as a “topper,” rejuvenating hydrophobic properties and extending the coating’s life. For daily drivers not subjected to concours judging, a quality spray sealant applied every 3-4 months provides exceptional protection that satisfies 95% of car owners. The key difference is hardness and thickness—ceramic coatings physically build a measurable layer, while spray sealants create a microscopically thin yet effective barrier.

Essential Features to Evaluate Before Buying

When evaluating spray sealants, durability claims should be your first scrutiny point. Manufacturers often advertise longevity based on ideal conditions—garaged vehicles, gentle hand washing, mild climates. Real-world performance typically runs 30-50% shorter. Look for products specifying “months” rather than “weeks,” and cross-reference enthusiast forums for unbiased longevity reports.

Hydrophobic behavior varies dramatically between formulations. Premium products create tight beading with contact angles exceeding 110 degrees, causing water to roll off at speed. Cheaper options may sheet water adequately but lack that satisfying beading action. UV inhibitor concentration directly impacts fade prevention, particularly crucial for vehicles parked outdoors. The best formulations contain stabilized UV absorbers that sacrificially degrade before your clear coat does.

Durability Expectations: What Real-World Performance Looks Like

Understanding realistic durability requires factoring your specific environment. A vehicle garaged nightly in Southern California might see 5-6 months from a quality spray sealant. The same product on a daily driver in Minnesota facing road salt, harsh winters, and automatic car washes might need reapplication every 6-8 weeks. Climate, washing methods, and storage conditions drastically affect longevity.

Manufacturers’ claims of “up to 12 months” should be viewed skeptically unless you’re dealing with a true ceramic spray coating with specific curing requirements. For standard spray sealants, 3-4 months represents excellent performance. The product hasn’t necessarily “failed” after this period—protection diminishes gradually. You’ll notice decreased water beading and easier dirt accumulation, signaling it’s time for reapplication. Tracking your personal results with a maintenance log helps establish realistic expectations for your specific situation.

Hydrophobic Properties and Water Behavior

The hydrophobic effect isn’t just cosmetic—it serves practical functions. Water beading reduces water spotting minerals left behind after rain or washing. When water rolls off in tight beads, it carries away light dust and contaminants. This self-cleaning characteristic, known as the “lotus effect,” means your vehicle stays cleaner between washes and cleans more easily when you do wash it.

Evaluate hydrophobic performance by observing bead size and behavior. Small, uniform beads that race across the surface indicate excellent surface tension reduction. Large, flat droplets suggest marginal performance. The best spray sealants maintain this behavior through multiple washes and even light detergent exposure. Some formulations incorporate surfactants that actively repel water for weeks, while cheaper options lose this effect after the first rainfall.

UV Protection and Oxidation Resistance

Clear coat oxidation—the chalky, dull appearance on neglected paint—results from UV radiation breaking down the resin binders in automotive paint. Quality spray sealants contain UV stabilizers that absorb these harmful rays and dissipate the energy as heat, sacrificing themselves instead of your paint. This protection is particularly critical for horizontal surfaces like hoods and roofs that receive maximum sun exposure.

The concentration and type of UV inhibitors separate premium from budget products. Look for sealants specifically mentioning “UV absorbers” or “UV stabilizers” rather than generic “UV protection” claims. Some advanced formulations include hindered amine light stabilizers (HALS) that regenerate themselves, providing longer-lasting UV defense. For vehicles in high-UV environments like Arizona or Florida, prioritize this feature above almost all others—it’s your primary defense against premature clear coat failure.

Chemical Resistance and Environmental Contaminants

Road salt, acid rain, bird droppings, bug splatter, and industrial fallout represent chemical threats that etch and stain paint. Spray sealants create a sacrificial barrier that resists these contaminants, buying you time to remove them before damage occurs. The chemical resistance correlates directly with the sealant’s polymer density and cross-linking capability.

Premium formulations withstand exposure to pH-neutral car wash soaps indefinitely and resist degradation from harsh chemicals for reasonable periods. However, no spray sealant provides the chemical resistance of a professional ceramic coating. Bird droppings should still be removed within 24-48 hours, and bug splatter shouldn’t bake on for weeks. The sealant simply gives you a larger window of safety and makes removal easier. For winter road salt protection, reapply every 6-8 weeks in harsh climates, as salt’s abrasive and chemical action gradually compromises the barrier.

Understanding Different Formulation Types

Not all spray sealants share the same chemical foundation, and understanding these differences helps match products to your needs. The three primary categories—SiO2-infused, polymer-based, and hybrid formulations—each offer distinct characteristics in application feel, curing behavior, and ultimate performance.

SiO2-Infused Spray Sealants

These ceramic-infused sprays contain suspended silicon dioxide particles that create a harder, more glass-like finish than traditional polymers. They typically require a short curing period (30 minutes to 2 hours) where the SiO2 particles align and bond with the surface. The result is enhanced hardness, improved chemical resistance, and water behavior that mimics true ceramic coatings.

Application requires more attention than polymer sprays. You must apply in thin, even layers to avoid streaking or high spots where SiO2 concentrates. They perform best on properly decontaminated paint and often benefit from a “flash” time before buffing. The trade-off for superior performance is a slightly more demanding application process. Durability typically ranges from 4-8 months, making them excellent quarterly maintenance products.

Polymer-Based Spray Sealants

These traditional synthetic sealants use acrylic, polyurethane, or fluoropolymer chemistry to create flexible, durable protection. They’re incredibly forgiving during application—spray on, spread evenly, and buff off without worrying about cure times or high spots. This user-friendliness makes them ideal for beginners or those seeking maximum convenience.

Performance emphasizes gloss and slickness over extreme hardness. They excel at making paint feel silky smooth and look deeply wet, particularly on lighter colors where SiO2 sprays can sometimes appear slightly hazy. Durability generally spans 2-4 months, making them perfect for monthly or bimonthly applications. Polymer sprays also tend to be more economical, offering better cost-per-application ratios for budget-conscious enthusiasts.

Hybrid Formulations: The Best of Both Worlds

Hybrid sprays combine SiO2 with polymer resins, attempting to capture ceramic hardness with polymer ease-of-use. These formulations have surged in popularity, offering 3-6 month durability with application processes nearly as simple as pure polymer sprays. The polymers act as a carrier and flexibility agent, while SiO2 provides the hydrophobic punch and hardness.

Performance varies widely between manufacturers based on their SiO2-to-polymer ratio. Some lean heavily toward ceramic characteristics, requiring careful application, while others prioritize user experience with marginal ceramic benefits. Reading detailed reviews helps identify which hybrids truly deliver balanced performance versus those making marketing claims. These represent the current sweet spot for most consumers, offering excellent results without professional-level application demands.

Application Mastery: Techniques for Professional Results

Achieving showroom-quality results requires more than spraying and wiping. Professional detailers follow specific protocols that maximize bonding, ensure even coverage, and eliminate common issues like streaking or high spots. The difference between amateur and professional outcomes often lies in surface preparation and application environment.

Surface Preparation: The Non-Negotiable First Step

No spray sealant performs optimally on contaminated paint. Begin with a thorough wash using a pH-neutral shampoo, followed by a chemical decontamination with iron remover to dissolve embedded brake dust and rail dust particles. Follow this with a mechanical decontamination using a clay bar or clay mitt to remove bonded contaminants like tree sap and overspray.

The final preparation step involves wiping down with isopropyl alcohol (IPA) diluted 1:1 with water or a dedicated surface prep spray. This removes any residual oils from previous products, ensuring the sealant bonds directly to the clear coat. Skipping this step risks reduced durability and potential bonding failures. For vehicles with heavy contamination, this prep process might take an hour, but it’s essential for maximum performance and longevity.

Step-by-Step Application Process

Work in a shaded area with surface temperatures between 60-80°F. Avoid direct sunlight, which causes premature flashing and potential streaking. Shake the product vigorously for 30 seconds to ensure uniform distribution of active ingredients. Work panel-by-panel, spraying 2-3 light mists onto the surface—not onto your towel.

Immediately spread the product using a plush microfiber applicator or towel in cross-hatch patterns to ensure even distribution. Flip to a clean side of the towel and buff to a high gloss using light pressure. The key is working small sections (roughly 2’x2’) to prevent the product from drying before buffing. For SiO2-infused products, allow a 30-60 second flash time before buffing. Maintain separate towels for application and removal to prevent product buildup that causes streaking.

Curing Time and Layering Strategies

Most spray sealants achieve initial cure within 1-2 hours, but full chemical bonding continues for 24 hours. During this period, avoid water exposure, washing, or parking under trees where sap or bird droppings might contaminate the fresh coating. The first wash should be gentle, using only pH-neutral shampoo without aggressive brushing.

Layering can enhance performance, but technique matters. Apply the first layer thinly, allow it to cure for the manufacturer-recommended time (typically 1-2 hours), then apply a second layer. This builds protection thickness rather than simply adding more product on top. Some enthusiasts apply monthly layers, creating a sacrificial stack that extends overall protection. However, diminishing returns appear after 2-3 layers—more isn’t always better. Focus on proper prep and application technique rather than excessive layering.

Surface Compatibility: What You Can and Can’t Protect

Modern spray sealants boast impressive versatility, but understanding limitations prevents costly mistakes. Painted surfaces—clear coat, single-stage, and even properly cured fresh paint—accept spray sealants beautifully. They enhance gloss and provide sacrificial protection across all automotive paint types.

Glass surfaces benefit enormously from spray sealants, creating hydrophobic properties that improve visibility during rain and make ice removal easier in winter. Wheels and brake components respond well, though high-temperature formulations specifically designed for wheels last longer under extreme heat cycles. Plastic trim pieces can be protected, but avoid products with heavy solvents that might cause whitening or discoloration on raw, uncoated plastic.

Never apply spray sealants to raw aluminum, chrome, or bare metal surfaces that haven’t been clear-coated. The polymers can create uneven appearances and prove difficult to remove. Fresh paint requires a 30-60 day curing period before applying any sealant, as the outgassing process can interfere with bonding and trap solvents. Convertible tops, whether canvas or vinyl, require dedicated fabric or vinyl protectants—standard paint sealants may damage these materials.

Maintenance and Longevity Optimization

Proper maintenance dramatically extends sealant life. Establish a washing routine using the two-bucket method with grit guards, pH-neutral shampoo, and microfiber wash mitts. Avoid automatic car washes with harsh brushes that mechanically abrade the sealant layer. Wash frequency depends on environment, but every 1-2 weeks maintains optimal appearance and prevents contaminant buildup.

Between washes, use a spray detailer or maintenance booster compatible with your sealant chemistry. These “topper” products revitalize hydrophobic properties and add sacrificial layers without requiring full reapplication. They’re particularly valuable after heavy rain or long trips where bug splatter and road grime have compromised the surface.

Seasonal reapplication schedules vary by climate. In moderate conditions, quarterly applications suffice. Harsh winter environments benefit from monthly applications during salt season. Track your sealant’s performance by observing water behavior after washing—when beading diminishes or becomes irregular, it’s time to reapply. Maintaining a detailed log of applications, products used, and observed performance helps refine your maintenance schedule.

Common Application Mistakes That Ruin Results

Over-application ranks as the most frequent error. More product doesn’t equal more protection—it creates streaking, extends cure times unnecessarily, and wastes money. Two light sprays per panel is sufficient; the product should spread thinly and buff off easily. If you’re experiencing heavy residue or difficulty buffing, you’re using too much.

Working in direct sunlight or on hot panels causes premature drying, leading to high spots and streaking that require polishing to remove. Always work in shade and ensure panels are cool to the touch. Using dirty or low-quality towels introduces swirl marks and prevents proper buffing. Invest in high-quality, edgeless microfiber towels designated specifically for sealant application.

Skipping surface preparation is catastrophic. Applying sealant over existing wax, polish residue, or contaminants prevents bonding, reducing durability to days rather than months. The sealant may look good initially but washes away with the first rain. Finally, impatience during cure time compromises bonding. That 24-hour waiting period before washing isn’t a suggestion—it’s critical for maximum adhesion.

Environmental and Health Considerations

Volatile organic compounds (VOCs) in spray sealants have decreased significantly, but proper ventilation remains essential. Always apply in well-ventilated areas—outdoors or in garages with doors open. Wear nitrile gloves to prevent skin contact, which can cause dryness or irritation with repeated exposure. A simple N95 mask protects against inhalation of fine mist particles during extended application sessions.

Disposal requires attention. Never pour leftover product down drains. Allow empty containers to fully evaporate outdoors before recycling, and absorb any spills with cat litter or absorbent pads. Many modern formulations are water-based and more environmentally benign than solvent-heavy predecessors, but they still contain active chemicals that require responsible handling.

Consider the environmental impact of your washing routine. Sealants reduce wash frequency by keeping cars cleaner longer, decreasing water usage and chemical runoff. However, the microplastics from microfiber towels during washing present an emerging concern. Using a filter bag in your washing machine captures these particles, preventing them from entering waterways.

Cost Analysis: Budgeting for Protection

Spray sealants range from $10 to $40 for a 16-24 ounce bottle, with premium ceramic-infused formulas commanding higher prices. A single bottle typically provides 8-12 applications for an average sedan, translating to a per-application cost of $1.50 to $5. Compare this to professional detailing services charging $50-$100 for sealant application, and the DIY approach offers compelling value.

Factor in supporting supplies: quality microfiber towels ($3-5 each, needing replacement after 15-20 uses), surface prep sprays ($15-20 per bottle), and iron removers ($20-30) for comprehensive decontamination. The initial investment might reach $100, but these supplies last multiple application cycles. Amortized over a year of quarterly applications, you’re investing roughly $5-8 per month in paint protection—less than two premium car washes.

The hidden cost is your time. A proper application, including preparation, takes 2-3 hours initially, though subsequent maintenance applications require just 30 minutes. Weigh this against the cost of paint correction due to neglected protection, which can easily exceed $500. From a long-term vehicle value perspective, consistent sealant application preserves paint condition, directly impacting resale value.

Professional vs. DIY: Making the Right Choice

Professional application offers expertise, specialized equipment, and controlled environments that maximize results. Detailers perform multi-stage decontamination, precise application, and often provide warranties. However, the cost premium—typically $75-150 per application—adds up quickly for quarterly maintenance. Professional services make sense for high-value vehicles, severe correction needs, or owners lacking time and inclination.

DIY application has never been more accessible. Modern spray sealants are specifically formulated for user-friendliness, eliminating the risks associated with professional ceramic coatings. The learning curve is minimal, and the satisfaction of maintaining your own vehicle is significant. For daily drivers and moderately valuable vehicles, DIY represents the smart choice, especially when you consider the ability to touch up protection monthly without scheduling appointments.

The hybrid approach maximizes benefits: have a professional perform initial paint correction and apply a long-term ceramic coating, then maintain it yourself with spray sealants. This combines professional foundation with convenient, cost-effective maintenance. Many professional detailers now sell maintenance packages that include periodic inspections and DIY product recommendations, offering the best of both worlds.

Seasonal Application Strategies

Spring applications should focus on pollen and bug season preparation. Apply a robust sealant in early spring before pollen counts peak, creating a barrier that prevents pollen from bonding and makes bug removal easier. The mild temperatures of spring provide ideal curing conditions, maximizing bonding and longevity.

Summer demands emphasize UV protection and heat resistance. Apply sealant in early morning or evening to avoid extreme panel temperatures. Consider products with higher SiO2 content for improved heat resistance. Monthly topper applications during summer maintain performance despite intense sun and frequent washing due to dust and road grime.

Fall preparation targets leaf tannins, acorns, and increased rain. A fresh sealant application before leaf fall prevents staining from decomposing organic matter. The cooler temperatures of fall again provide excellent curing conditions. In regions with early frost, ensure applications are completed when temperatures remain above 50°F for the full cure period.

Winter protection is arguably most critical. Road salt, magnesium chloride, and harsh de-icing chemicals attack paint with ferocity. Apply a durable sealant before the first salt application, and consider monthly maintenance sprays during the worst months. Focus extra product on lower panels, wheel wells, and behind wheels where salt spray concentrates. Store your vehicle in a garage when possible, but if outdoor storage is necessary, ensure the sealant is fully cured to withstand freezing temperatures.

Troubleshooting Common Issues

Streaking and high spots typically indicate over-application or insufficient buffing. Correct this by spraying a light mist of quick detailer on the affected area and re-buffing with a clean microfiber. For stubborn streaks, a light polish may be necessary to remove excess product. Prevention through thin application and immediate buffing is far easier than correction.

Poor water behavior after application suggests surface contamination prevented bonding. The only solution is stripping the sealant with an IPA wipe-down or light polish and reapplying after proper decontamination. Always test water behavior on a small section immediately after application; if beads don’t form within minutes, stop and address prep issues.

Durability falling short of expectations usually traces to environmental factors or improper maintenance. Review your washing products—are they pH-neutral? Check for automatic car wash usage with harsh chemicals. Consider environmental contaminants like industrial fallout or agricultural chemicals that accelerate degradation. Adjust your reapplication schedule based on observed performance rather than manufacturer claims.

Frequently Asked Questions

How long does a spray sealant really last on a daily driver?

Real-world durability typically spans 2-4 months for polymer-based formulas and 4-6 months for SiO2-infused versions on daily-driven vehicles. Factors like climate, washing frequency, garage storage, and environmental contaminants significantly impact longevity. Track your specific results by monitoring water beading after washing—when performance degrades, it’s time to reapply.

Can I apply a spray sealant over existing wax or ceramic coating?

Applying over existing wax wastes product, as the sealant bonds to the wax rather than the paint, reducing durability to weeks. Always strip old wax with an IPA wipe-down first. Over ceramic coatings, spray sealants work excellently as maintenance toppers, rejuvenating hydrophobic properties and extending coating life. Ensure the coating is clean and decontaminated before applying the topper.

What’s the difference between a spray sealant and a quick detailer?

Quick detailers contain minimal protective ingredients, focusing on lubrication for dust removal and adding temporary gloss. They last days, not months. Spray sealants contain concentrated polymers or SiO2 that chemically bond and provide measurable protection. The price difference reflects this—sealants cost more but deliver genuine protection versus cosmetic enhancement.

How many layers of spray sealant should I apply?

Two properly applied layers offer optimal protection, with the second layer applied 1-2 hours after the first cures. Additional layers provide diminishing returns and increase streaking risk. Focus on perfecting application technique and surface preparation rather than stacking excessive layers. Monthly maintenance toppers are more effective than multiple base layers.

Will spray sealants protect against rock chips and scratches?

No, spray sealants provide chemical and environmental protection but don’t add measurable physical hardness to prevent rock chips or scratches. They may reduce micro-marring from light dust due to increased slickness, but for stone chip protection, consider paint protection film (PPF). Sealants complement PPF excellently by protecting the film itself from UV degradation and staining.

Can I use spray sealants on matte or satin finishes?

Standard sealants may add unwanted gloss to matte finishes. Use sealants specifically formulated for matte paint—these contain the same protective polymers but without gloss enhancers. Always test on an inconspicuous area first. Some matte-specific sprays also fill minor imperfections without altering the desired flat appearance.

How soon after painting can I apply a spray sealant?

Fresh paint requires 30-60 days of curing before applying any sealant. During this period, solvents evaporate from the paint, and the clear coat hardens. Applying sealant too early traps these solvents, potentially causing adhesion issues or dulling. When in doubt, wait the full 60 days. For factory fresh cars, the paint is fully cured before delivery, so immediate protection is safe.

Do spray sealants work on vinyl wraps and PPF?

Most spray sealants are safe and highly beneficial for vinyl wraps and paint protection film. They protect against UV fading, staining, and make cleaning easier. Avoid products with harsh solvents that might degrade vinyl adhesives. SiO2-infused sprays particularly excel on PPF, restoring the self-healing properties and maintaining clarity. Always confirm compatibility with your wrap/PPF manufacturer.

What’s the best temperature range for applying spray sealants?

Ideal application occurs between 60-80°F with low humidity. Cooler temperatures slow curing but don’t harm results—just extend the before-washing period. Temperatures above 85°F cause premature flashing, increasing streaking risk. Never apply in freezing conditions; the sealant won’t properly bond. If you must apply in marginal conditions, work in smaller sections and adjust cure times accordingly.

How do I remove spray sealant if I’m unhappy with the results?

Remove fresh sealant within minutes using the same product as a lubricant—spray more on the area and immediately buff off. For cured sealant, use an IPA wipe-down (50% isopropyl alcohol, 50% water) or a light paint cleanser. Stubborn buildup may require a fine polish. This removal ease is actually a benefit—unlike permanent coatings, mistakes are easily correctable without professional intervention.