When your vehicle’s paint faces daily assault from UV rays, acid rain, road salt, and industrial fallout, a durable protective layer isn’t just a luxury—it’s essential insurance for your investment. Paint sealants represent the sweet spot between traditional carnauba waxes and modern ceramic coatings, offering synthetic protection that can last months instead of weeks without the permanent commitment or steep price tag of professional-grade ceramics. But not all sealants are created equal, and understanding what drives longevity can mean the difference between protection that survives a single winter and a shield that endures multiple seasons of harsh driving conditions.

The automotive detailing world has evolved dramatically, with polymer chemistry advancing at a pace that leaves many enthusiasts confused about what actually matters for long-term durability. This comprehensive guide cuts through marketing hype and technical jargon to reveal the science, application strategies, and maintenance protocols that truly extend sealant life. Whether you’re a weekend warrior looking to maximize your DIY efforts or simply want to make informed decisions about professional services, these insights will help you achieve the longest-lasting paint protection possible.

Top 10 Paint Sealant

Detailed Product Reviews

1. CERAKOTE® Platinum Rapid Ceramic Paint Sealant Spray - 14 oz Bottle - Maximum Gloss & Shine – Extremely Hydrophobic – Unmatched Slickness - Ceramic Spray Coating - 50 Wash Rating

Overview: CERAKOTE’s Platinum Rapid Ceramic Paint Sealant represents a breakthrough in DIY automotive protection, delivering professional-grade ceramic coating benefits in a user-friendly spray format. This 14-ounce bottle promises exceptional durability with its industry-leading 50 wash rating, making it a compelling alternative to expensive professional applications.

What Makes It Stand Out: The true ceramic technology sets this apart from typical waxes and synthetic sealants. The extreme hydrophobic properties create dramatic water beading and sheeting effects, while the unmatched slickness provides a tactile quality that must be felt to be believed. The simple spray-and-buff application eliminates the complexity traditionally associated with ceramic coatings.

Value for Money: At $19.69 for 14 ounces, this product offers remarkable value compared to professional ceramic coatings costing hundreds of dollars. While premium DIY sealants typically range $15-30, the 50-wash longevity and genuine ceramic formulation justify the price point. Each application provides months of protection, making it cost-effective for regular use.

Strengths and Weaknesses: Strengths include exceptional water repellency, genuine durability, mirror-like gloss, and straightforward application. The slick finish helps prevent dirt adhesion. Weaknesses involve requiring meticulous surface preparation for optimal bonding, and it won’t match the multi-year durability of professional-grade coatings. Performance may vary based on environmental conditions.

Bottom Line: For car enthusiasts seeking professional results without professional prices, CERAKOTE Platinum delivers. It bridges the gap between traditional waxes and expensive ceramic coatings, offering impressive longevity and protection that’s hard to beat at this price point.

2. Rust-Oleum 334022 Painter’s Touch 2X Ultra Cover Spray Paint, 12 oz, Matte Clear

Overview: Rust-Oleum’s Painter’s Touch 2X Ultra Cover in Matte Clear is a versatile, oil-based spray coating designed for multi-surface protection. This 12-ounce can delivers a practical solution for both interior and exterior projects, offering reliable coverage across diverse materials from wood and metal to plastic and masonry.

What Makes It Stand Out: The 2X Ultra Cover technology provides exceptional coverage efficiency, effectively doubling the surface area per can compared to standard sprays. Its oil-based formula creates a durable, chip-resistant barrier that dries to the touch in just 20 minutes. The matte finish offers a contemporary, non-reflective appearance that conceals imperfections while providing robust protection.

Value for Money: At $6.19 ($0.52 per ounce), this represents exceptional budget-friendly value. Comparable multi-surface clear coats typically range $8-15, making this an economical choice for large projects or frequent users. The 12 square foot coverage per can maximizes utility for the price.

Strengths and Weaknesses: Strengths include rapid drying time, versatile substrate compatibility, durable oil-based protection, and excellent hide. The matte finish is ideal for modern aesthetics. Weaknesses involve oil-based cleanup requiring mineral spirits, potential for uneven application on vertical surfaces, and the matte sheen may not suit projects requiring gloss. Strong fumes necessitate proper ventilation.

Bottom Line: This is a workhorse product for DIYers needing reliable, affordable clear protection across multiple surfaces. While not specialized for automotive or high-gloss applications, its versatility and price make it an essential staple for any home workshop.

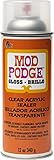

3. Mod Podge Spray Acrylic Sealer that is Specifically Formulated to Seal Craft Projects, Dries Crystal Clear is Non-Yellowing No-Run and Quick Drying, 12 ounce, Gloss

Overview: Mod Podge’s Spray Acrylic Sealer brings the brand’s legendary craft expertise into an aerosol format, offering crafters a convenient 12-ounce solution for protecting finished projects. Specifically formulated for artistic applications, this sealer delivers a crystal-clear, glossy finish that preserves and enhances creative work.

What Makes It Stand Out: The non-yellowing formula ensures long-term clarity, critical for preserving artwork and photographs. Its no-run consistency prevents the drips and sags common with less specialized sealers. The quick-drying properties accelerate project completion, while the trusted Mod Podge name guarantees compatibility with decoupage and mixed-media applications.

Value for Money: Priced at $10.49 ($0.87 per ounce), this sits in the mid-range for craft sealers. While cheaper generic options exist, the Mod Podge premium buys proven reliability, consistent results, and the non-yellowing guarantee. For serious crafters, this quality assurance justifies the modest price increase over budget alternatives.

Strengths and Weaknesses: Strengths include versatile surface compatibility, easy cleanup with nozzle-clearing spray feature, trusted brand reputation, and true non-yellowing performance. The gloss finish enhances color vibrancy. Weaknesses involve limited durability for heavy-duty or outdoor use, not suitable for automotive applications, and the price runs higher than basic acrylic sprays. Gloss-only option limits finish choices.

Bottom Line: An indispensable tool for crafters seeking reliable, professional-quality sealing. For protecting decoupage, artwork, and decorative items, its specialized formulation outperforms general-purpose sealers. The non-yellowing promise alone makes it worth the investment for precious projects.

4. Meguiar’s Professional Synthetic Sealant 2.0 M2116 - Premium Synthetic Car Paint Sealant, Long-Lasting Protection, Additional Gloss and Hydrophobic Properties for High Water Beading, 16 Oz Liquid

Overview: Meguiar’s Professional Synthetic Sealant 2.0 M2116 represents the evolution of synthetic polymer technology for automotive paint protection. This 16-ounce liquid formulation targets serious detailers seeking professional-grade results, delivering advanced protection through technologically sophisticated polymer chemistry that bonds to paint surfaces.

What Makes It Stand Out: The synthetic polymer formulation creates a hydrophobic barrier that produces dramatic water beading and sheeting action. Its unique ability to visually eliminate fine scratches and swirls while amplifying gloss sets it apart from conventional sealants. The formula glides on effortlessly and wipes off without resistance, reducing application fatigue.

Value for Money: At $25.32 ($1.58 per fluid ounce), this is a premium-priced product positioned for professional and enthusiast use. While significantly more expensive than consumer-grade sealants ($10-15), it delivers comparable performance to coatings costing $40-60. The concentrated formula provides multiple applications per bottle, offsetting the initial investment.

Strengths and Weaknesses: Strengths include exceptional gloss enhancement, superior hydrophobic properties, scratch-masking capabilities, and smooth, easy application. The deep, reflective finish rivals more expensive products. Weaknesses involve the premium price point, requiring careful technique for optimal results, and it may not match the longevity of true ceramic coatings. Not ideal for casual users seeking quick applications.

Bottom Line: For detailing professionals and serious enthusiasts, this synthetic sealant justifies its premium price through superior performance and durability. It strikes an excellent balance between traditional waxes and ceramic coatings, delivering professional results that enhance and protect automotive paint beautifully.

5. Krylon I00500A07 12-Ounce Triple Thick Clear Glaze Aerosol Spray,High-Gloss

Overview: Krylon’s Triple Thick Clear Glaze delivers an impressively dense protective coating in a convenient aerosol format. This 12-ounce can promises equivalent coverage to three layers of conventional clear coatings, targeting crafters and DIYers seeking maximum gloss buildup with minimal effort. The high-gloss finish provides permanent protection for various creative projects.

What Makes It Stand Out: The triple-thick formulation builds substantial film depth in a single application, saving significant time compared to multiple thin coats. This unique characteristic makes it ideal for achieving glass-like finishes on dimensional objects. The permanent, protective glaze works exceptionally well on polymer clay, bisque, plaster, and decorative items requiring robust, high-shine protection.

Value for Money: At $6.47 ($0.54 per ounce), this is remarkably affordable considering its concentrated formulation. Effectively providing triple coverage, the real cost per equivalent coat drops to approximately $0.18 per ounce—outstanding value for craft applications. Comparable gloss sprays cost $8-12 without the thickness advantage.

Strengths and Weaknesses: Strengths include rapid buildup of high-gloss finish, excellent value, permanent protection, and specialized formulation for craft materials. The single-coat application reduces drying time and dust contamination risks. Weaknesses involve potential for runs if over-applied, limited to craft-scale projects, unsuitable for automotive or large surface areas, and the thick coating may obscure fine details on intricate pieces.

Bottom Line: An exceptional value for crafters needing thick, glassy finishes without brush marks or multiple coats. While specialized for artistic applications, within its niche it delivers unmatched efficiency and results. Perfect for polymer clay artists and decorative painters seeking professional-grade gloss with amateur-friendly application.

6. Minwax 233334444 Polycrylic Protective Wood Finish, Clear Satin, ½ Pint

Overview: Minwax Polycrylic delivers reliable protection for interior wood projects in a convenient water-based formula. This ½ pint container provides an ultra-fast drying clear satin finish that safeguards furniture, cabinets, doors, and woodwork against daily wear, scratches, and spills while preserving the natural beauty of the wood grain.

What Makes It Stand Out: The two-hour recoat time dramatically accelerates project completion compared to traditional oil-based polyurethanes. Its crystal-clear, non-yellowing properties make it ideal for light woods like maple and birch, while the low-odor formula allows comfortable indoor application. The water-based composition ensures effortless soap-and-water cleanup, eliminating harsh chemical solvents from your workspace.

Value for Money: At $1.47 per fluid ounce, this premium finish costs slightly more than oil-based alternatives but justifies the price through time savings and convenience. The 8-ounce size suits small to medium projects perfectly, preventing waste from larger containers drying out. DIYers avoid purchasing mineral spirits for cleanup, creating additional cost efficiency.

Strengths and Weaknesses: Strengths: Ultra-fast drying enables same-day project completion; non-ambering finish preserves light wood colors; low odor suitable for indoor use; excellent compatibility with all Minwax stains; easy brush cleanup; durable scratch resistance.

Weaknesses: Requires careful application with high-quality synthetic brushes to avoid visible brush strokes; less durable than oil-based polyurethane for high-traffic surfaces; not suitable for exterior use; multiple thin coats necessary for optimal protection.

Bottom Line: Minwax Polycrylic excels for interior wood projects where time, convenience, and appearance matter most. Choose this finish for light-colored woods and situations requiring quick turnaround. While not the toughest option available, its user-friendly nature makes it perfect for DIYers seeking professional-looking results without harsh chemicals or extended drying times.

7. P&S Bead Maker Paint Sealant – Easy Spray & Wipe Protectant for Cars, Boats & RVs – Hydrophobic Gloss & UV Protection – Safe for All Surfaces - 1 Gallon

Overview: P&S Bead Maker revolutionizes vehicle protection with a professional-grade spray-and-wipe sealant that works on wet or dry surfaces. This one-gallon container delivers hydrophobic technology and UV protection for cars, boats, RVs, and more, creating a showroom-worthy shine without complicated application processes.

What Makes It Stand Out: The versatile spray-and-wipe formula eliminates traditional wax application hassles, working safely across paint, glass, plastic, rubber, and metal surfaces. Advanced polymer technology creates extreme water beading while built-in UV filters prevent sun damage and oxidation. The bulk sizing provides professional detailers and serious enthusiasts with economical, high-volume protection.

Value for Money: At just $0.31 per fluid ounce, this gallon represents exceptional value compared to $15-20 retail bottles of similar sealants. The concentrated formula requires minimal product per application, stretching one gallon across multiple vehicles for an entire year. Professional-grade results at consumer pricing make this a smart investment for fleet owners or car clubs.

Strengths and Weaknesses: Strengths: Effortless spray-and-wipe application saves hours; universal surface compatibility simplifies detailing; outstanding hydrophobic properties repel water and contaminants; UV protection prevents fading; cost-effective bulk sizing; professional-quality gloss enhancement.

Weaknesses: One-gallon size may be excessive for casual users with single vehicles; requires quality microfiber towels for proper buffing; initial cure time needed for maximum durability; over-application can cause streaking if not buffed properly.

Bottom Line: P&S Bead Maker is a game-changer for serious vehicle enthusiasts and professionals seeking efficient, high-quality protection. The gallon size delivers unmatched per-ounce value while the versatile formula replaces multiple specialized products. For those maintaining several vehicles or running a detailing business, this sealant is an essential, cost-effective solution.

8. Nu Finish Once a Year Polish and Sealant, Car Polish and Paint Sealant with 3-in-1 Ceramic Technology to Repair, Seal and Repel, 16 fl oz Bottle

Overview: Nu Finish Once a Year Polish promises extended protection through innovative ceramic technology that repairs, seals, and repels contaminants in a single application. This 16-ounce bottle delivers a unique liquid polish requiring no strenuous rubbing or buffing, making it accessible for car owners seeking minimal maintenance with maximum durability.

What Makes It Stand Out: The 3-in-1 ceramic formula actively fills fine swirls and scratches while creating a hydrophobic barrier that lasts up to twelve months. Unlike conventional waxes, application works even in direct sunlight without streaking or hazing. The no-buff process eliminates elbow grease, appealing to users who want professional results without professional effort.

Value for Money: Priced at $11.49 for 16 ounces, this sealant costs less than premium ceramic coatings while claiming similar longevity. When compared to monthly wax applications, the annual protection claim reduces both product costs and time investment significantly. The scratch-filling capability adds value by improving appearance beyond simple protection.

Strengths and Weaknesses: Strengths: Simple no-buff application saves time and effort; effective ceramic technology provides genuine water beading; works in sunlight unlike many competitors; fills minor imperfections; long-lasting protection reduces maintenance frequency; affordable entry into ceramic protection.

Weaknesses: “Once a year” claim varies based on climate and washing frequency; not a substitute for professional ceramic coatings; may not bond well to poorly prepared surfaces; limited scratch repair capability for deeper marks; requires clean surface for optimal adhesion.

Bottom Line: Nu Finish delivers impressive convenience and solid performance for budget-conscious car owners wanting ceramic benefits without professional installation costs. While the annual claim requires realistic expectations, the product genuinely reduces maintenance frequency. Ideal for daily drivers in moderate climates where simple application and decent protection outweigh absolute maximum durability.

9. LANBEIDE 200ML Diamond Painting Sealer with Silicone Brush, Updated 5D Diamond Painting Glue Sealer Permanent Hold & Shine Effect Conserver for Diamond Painting and Jigsaw Puzzles (7 OZ)

Overview: LANBEIDE Diamond Painting Sealer preserves intricate craft projects with a specialized PVA-based formula designed for 5D diamond paintings and jigsaw puzzles. This 200ml bottle includes a silicone brush applicator, providing crafters with a dedicated solution to permanently secure and enhance their time-intensive creations with a protective, glossy finish.

What Makes It Stand Out: The included silicone brush ensures bubble-free, even application across delicate diamond facets without disturbing placement. The non-toxic, water-based PVA formula dries completely clear after an initial white film, creating a permanent bond that prevents diamond loss while adding a professional shine. Its versatility extends beyond diamond paintings to jigsaw puzzles, addressing multiple craft preservation needs.

Value for Money: At $9.99 for 7 ounces, this specialized sealer commands a premium over generic glues but justifies the cost through craft-specific design. The silicone brush eliminates separate tool purchases, while the precise formulation prevents damage to delicate diamond coatings. For crafters investing dozens of hours in projects, this protection is economically sensible.

Strengths and Weaknesses: Strengths: Silicone brush enables smooth, controlled application; non-toxic formula safe for family use; effective on both diamond paintings and puzzles; permanent hold prevents diamond loss; adds attractive glossy finish; larger volume suits multiple projects.

Weaknesses: 2-hour minimum cure time requires patience; initial white film can be alarming before drying; specialized use limits broader craft applications; PVA formula may not suit all puzzle types; brush quality varies occasionally based on user reports.

Bottom Line: LANBEIDE fills a specific niche perfectly, providing diamond painting enthusiasts and puzzle completers with peace of mind. The dedicated applicator and craft-safe formula make it worth the modest premium over multipurpose sealers. If you’ve invested significant time in diamond art or puzzles, this product is essential for long-term preservation and display-worthy results.

10. Mod Podge Matte Sealer, Glue & Finish: All-in-One Craft Solution- Quick Dry, Easy Clean, for Wood, Paper, Fabric & More. Non-Toxic - Craft with Confidence, Made in USA, 8 oz., Pack of 1

Overview: Mod Podge Matte Sealer serves as the ultimate multi-purpose craft adhesive, combining glue, sealer, and finish in one convenient 8-ounce bottle. This American-made formula works across diverse surfaces including wood, paper, fabric, and terra cotta, delivering a quick-drying matte finish that preserves project aesthetics while ensuring durable adhesion.

What Makes It Stand Out: The true all-in-one functionality eliminates purchasing separate adhesives and sealers, streamlining craft supplies. The quick-dry formula accelerates project completion, while soap-and-water cleanup simplifies workspace maintenance. Being non-toxic and proudly manufactured in the USA provides confidence for both classroom and home use, particularly for projects involving children.

Value for Money: At $0.50 per ounce, this 8-ounce size offers exceptional affordability for casual crafters and educators. The versatility replaces multiple single-purpose products, creating significant cost savings. Small size prevents waste while providing sufficient quantity for numerous decoupage and mixed-media projects, making it ideal for experimental crafters.

Strengths and Weaknesses: Strengths: Unmatched versatility across materials; non-toxic formula safe for all ages; quick drying enables rapid project progression; easy cleanup reduces frustration; matte finish suits most craft aesthetics; reliable American manufacturing quality; economical entry point.

Weaknesses: Not waterproof or highly durable for outdoor use; can remain slightly tacky in humid conditions; matte finish may not suit projects requiring gloss; multiple coats often necessary for durability; not suitable for heavy-duty bonding applications.

Bottom Line: Mod Podge Matte remains an indispensable craft room staple for its unmatched convenience and versatility. While specialized products excel in specific applications, nothing matches its all-purpose utility for everyday crafting. Perfect for beginners, teachers, and budget-conscious creators who need reliable performance across diverse projects without investing in numerous separate products.

Understanding Paint Sealants: The Science Behind Long-Lasting Protection

Paint sealants are synthetic polymer-based formulations engineered to bond with your vehicle’s clear coat, creating a hydrophobic barrier that repels contaminants and environmental damage. Unlike traditional waxes that sit on the surface, quality sealants undergo a molecular cross-linking process that essentially becomes part of your paint’s protective ecosystem. This chemical marriage is what gives modern sealants their impressive longevity claims, with some advanced formulas promising up to 12 months of protection under ideal conditions.

How Sealants Differ from Traditional Waxes

The fundamental difference lies in molecular structure. Carnauba wax, derived from palm leaves, creates a physical layer that breaks down quickly under heat and detergent exposure. Synthetic sealants utilize polymer chains that form a more resilient, temperature-stable matrix. While a premium wax might last 6-8 weeks, a well-applied sealant can survive 6-12 months because its synthetic backbone resists degradation from UV exposure and chemical contaminants far more effectively. Think of wax as a temporary raincoat versus a sealant as a bonded technical fabric.

Synthetic vs. Natural: Breaking Down the Composition

Modern sealants typically combine acrylic resins, amino-functional silicones, and proprietary polymer blends. The “synthetic” label isn’t just marketing—it indicates laboratory-engineered molecules designed for specific performance characteristics. These formulations exclude the natural oils and volatile compounds found in waxes that evaporate or oxidize over time. The result is a purer, more stable protective layer that maintains its hydrophobic properties and gloss long after natural alternatives have dissipated.

Key Factors That Determine Sealant Durability

Durability isn’t determined by a single ingredient but rather a complex interplay of chemical properties, application technique, and environmental conditions. Understanding these variables helps you evaluate products realistically rather than relying on manufacturer claims alone.

Polymer Technology and Cross-Linking

The heart of sealant longevity lies in cross-linking density. When applied, polymers form a three-dimensional network as solvents evaporate and molecules bond together. Higher cross-link density creates a tighter, more impermeable barrier. Advanced formulations use polymer architectures like siloxane backbones or fluoropolymers that create stronger molecular bonds. The curing process—often taking 12-24 hours—allows these chains to fully develop their protective matrix, which is why rushing this step dramatically reduces durability.

VOC Content and Environmental Resistance

Volatile Organic Compounds (VOCs) affect both application safety and final film quality. Lower VOC formulas generally produce harder, more durable films because they contain less evaporative solvent and more actual protective solids. However, VOC regulations vary by region, affecting available formulations. Premium sealants balance compliance with performance by using non-volatile reactive diluents that become part of the protective film rather than evaporating away.

Solid Content Percentage: What Matters Most

The percentage of non-volatile solids directly correlates with how much actual protective material remains after curing. A sealant with 20-30% solids will inherently outlast one with 10-15% solids, assuming similar polymer quality. This is why professional-grade sealants often feel thicker during application—they’re delivering more protective material per ounce. Unfortunately, most manufacturers don’t disclose this figure, making it a key question to ask when evaluating professional products.

Types of Paint Sealants for Maximum Longevity

Not all sealant categories offer the same durability profile. Understanding the distinctions helps you match product type to your specific needs and expectations.

Acrylic-Based Sealants

Acrylic sealants form the foundation of many consumer-grade products, offering 4-6 months of protection through thermoplastic polymer films. They’re user-friendly and cure quickly but lack the advanced cross-linking of premium formulas. Their durability comes from reasonable chemical resistance and UV stability, though they’re more vulnerable to harsh detergents and environmental pollutants than advanced polymer types. These are ideal for enthusiasts who reapply protection seasonally.

Polymer-Infused Formulas

These represent the mid-to-high tier, utilizing copolymer blends that create stronger molecular bonds. Often labeled as “synthetic polymer sealants,” these products incorporate multiple polymer types—like polyethylene and polytetrafluoroethylene (PTFE)—to balance hardness, flexibility, and chemical resistance. Expect 6-12 months of durability when properly applied, with superior performance against bird droppings, tree sap, and road grime compared to basic acrylics.

Graphene-Enhanced Sealants

The newest entrants leverage graphene nanoplatelets to create an electrically conductive network that enhances chemical resistance and water repellency. The graphene structure provides a tortuous path that contaminants can’t easily penetrate, while also dissipating static charge that attracts dust. Early real-world testing suggests these can exceed 12-month durability claims, particularly in harsh climates. The technology is still evolving, but initial results show exceptional resistance to water spotting and chemical etching.

SiO2-Infused Sealants

These hybrid products bridge the gap between traditional sealants and ceramic coatings by incorporating silicon dioxide (silica) particles into a polymer matrix. The SiO2 adds hardness and hydrophobicity beyond what polymers alone can achieve, creating a semi-permanent bond that can last 8-12 months. They’re more forgiving than pure ceramic coatings while delivering much of the durability benefit, making them increasingly popular among serious DIYers.

Application Techniques That Impact Durability

Even the most advanced sealant will fail prematurely if applied incorrectly. The application process is where theoretical longevity becomes real-world performance.

Surface Preparation: The Foundation of Longevity

Durability starts with pristine paint. Any contamination—oil, wax residue, iron particles, or tar—creates a barrier that prevents proper bonding. The preparation cascade should include: thorough wash, chemical decontamination with iron removers and tar removers, clay bar treatment for embedded particles, and finally an isopropyl alcohol wipe-down to remove any remaining oils. Skipping these steps can reduce sealant life by 50-70% as the protective layer bonds to contaminants rather than clear coat.

Layering Strategies for Extended Protection

While sealants don’t “layer” like waxes in the traditional sense, strategic application can enhance durability. A base layer applied thinly and allowed to fully cure (24 hours) creates the primary bond. A second “sacrificial” layer can then be applied to increase overall thickness and fill any microscopic gaps. Some advanced systems use complementary products—a base sealant followed by a topper containing additional UV inhibitors or hydrophobic agents. This isn’t about building infinite layers but creating a more complete protective system.

Curing Time: Why Patience Pays Off

The 12-24 hour cure time isn’t a suggestion—it’s a requirement for maximum polymer cross-linking. During this window, the sealant remains vulnerable to moisture, dust, and temperature fluctuations. Applying in a climate-controlled garage with minimal humidity ensures optimal film formation. Rushing this process by exposing the vehicle to rain or washing too soon interrupts the cross-linking, leaving a weaker, less durable film that may wash off within weeks.

Environmental Considerations for Sealant Performance

Your local climate and driving conditions should heavily influence your sealant choice and maintenance schedule. No product performs equally in all environments.

UV Resistance and Oxidation Prevention

UV absorbers and stabilizers are critical additives that prevent polymer degradation. In sun-intensive regions, look for sealants specifically formulated with benzotriazole or hindered amine light stabilizers (HALS). These sacrificial ingredients absorb UV radiation and neutralize free radicals before they can break down the polymer backbone. Without adequate UV protection, even the best polymer matrix will chalk and degrade within months of constant sun exposure.

Chemical Resistance: Road Salts and Contaminants

Winter climates demand exceptional chemical resistance. Road salts, magnesium chloride, and calcium deicers are highly corrosive and can penetrate weaker sealant films, leading to clear coat etching and staining. Premium sealants use fluoropolymers that create a low-energy surface, making it difficult for ionic contaminants to adhere or penetrate. Testing shows that sealants with high fluorine content maintain integrity through multiple winter seasons, while basic polymers fail after the first salt exposure.

Temperature Extremes and Thermal Cycling

Your vehicle’s paint experiences massive temperature swings—from sub-zero mornings to 200°F+ surface temperatures in summer sun. This thermal cycling causes expansion and contraction that can crack brittle sealant films. Quality formulations incorporate flexible polymer segments that accommodate movement without fracturing. In desert climates, sealants with high glass transition temperatures (Tg) remain stable and don’t soften or become tacky under intense heat.

The Role of Paint Correction Before Sealing

Applying a durable sealant over imperfect paint is like building a house on a cracked foundation. The underlying condition directly impacts how well the sealant bonds and how long it lasts.

Why Imperfections Compromise Durability

Scratches, swirl marks, and oxidation create microscopic edges and porous areas where sealants can’t form a uniform film. These defects act as stress concentrators, causing the protective layer to fail prematurely as it flexes and moves with the paint. Additionally, oxidized clear coat has reduced surface energy and poor bonding characteristics, causing sealants to delaminate in sheets rather than wearing evenly. A properly corrected surface provides a uniform, high-energy substrate that maximizes adhesion.

Proper Decontamination Procedures

Beyond paint correction, chemical decontamination is non-negotiable for durability. Iron particles embed in clear coat and rust underneath the sealant, causing it to lift. Tar and road film contain oils that interfere with polymer bonding. Use a pH-neutral iron remover that changes color as it dissolves ferrous contaminants, followed by a tar remover for organic deposits. Finish with a fine-grade clay bar and lubricant to mechanically remove anything left behind. This three-step process ensures the sealant contacts nothing but pure clear coat.

Maintenance Protocols to Maximize Sealant Lifespan

Durability isn’t just about application—it’s about what happens afterward. Proper maintenance can extend sealant life by months, while aggressive washing can destroy it in weeks.

Washing Techniques That Preserve Protection

Touchless or two-bucket wash methods are essential. Sealants fail from mechanical abrasion more than chemical degradation. Grit Guards in wash buckets, premium microfiber wash mitts, and strict no-scrubbing policies prevent micro-marring that compromises the sealant film. Use pH-neutral shampoos without gloss enhancers or waxes, which can interfere with the sealant’s hydrophobic properties. Avoid automatic car washes with brushes; the abrasive action can strip sealant layers in a single pass.

Topper Products: Do They Help or Hurt?

The debate rages on, but science supports strategic use of compatible toppers. Products containing similar polymer chemistry can replenish UV inhibitors and hydrophobic agents that degrade over time. However, using incompatible products—like silicone-based quick detailers on acrylic sealants—can create a gummy residue that actually reduces durability. If you choose to use toppers, select ones from the same technology family and apply them no more frequently than monthly. Over-application creates a thick, unstable layer prone to streaking and premature failure.

Professional vs. DIY Application: Durability Implications

While DIY application can achieve excellent results, professional application offers certain advantages that directly translate to longer-lasting protection.

Equipment and Controlled Environments

Professional detailers use paint thickness gauges to identify thin clear coat areas needing special care, infrared curing lamps to accelerate and ensure complete polymer cross-linking, and climate-controlled booths that eliminate humidity and temperature variables. These tools create optimal conditions that DIYers can’t easily replicate. The controlled environment alone can add 2-3 months to sealant lifespan by ensuring perfect film formation without contamination.

Skill Level and Its Impact on Longevity

Experience matters in achieving the micro-thin, uniform application that maximizes durability. Professionals know how to “read” the paint, adjusting pressure and product amount based on temperature, humidity, and paint type. They recognize when a panel needs additional preparation and can identify potential bonding issues before application. This expertise typically results in 15-25% longer durability compared to first-time DIY applications, even with identical products.

Cost vs. Durability: Finding the Sweet Spot

Price doesn’t always correlate directly with durability, but understanding the relationship helps avoid both overpaying and under-protecting.

Price Tiers and Expected Performance

Entry-level sealants ($15-25) typically use simpler acrylic polymers lasting 4-6 months. Mid-tier products ($30-50) incorporate advanced copolymers and better additive packages, delivering 6-9 months of protection. Premium sealants ($60-100) utilize proprietary polymer blends, high solid content, and specialized ingredients like graphene or SiO2, providing 9-12+ months of durability. The jump from mid to high tier often yields diminishing returns unless you’re in extreme climates or keep vehicles for many years.

Long-Term Value Calculations

Calculate cost per month of protection rather than upfront price. A $80 sealant lasting 12 months costs $6.67/month, while a $20 product lasting 4 months costs $5/month but requires triple the labor. Factor in your time value and the risk of paint damage from more frequent applications. For daily drivers in harsh conditions, premium sealants often prove more economical despite higher initial cost when you account for reduced correction frequency and longer intervals between applications.

Common Application Mistakes That Reduce Longevity

Even premium products fail when basic application errors occur. Recognizing these pitfalls is crucial for achieving advertised durability.

Over-application and Streaking Issues

More is not better with modern sealants. Over-application creates a thick film that cures unevenly, leaving high and low spots that fail at different rates. Excess product doesn’t bond properly and becomes a dust magnet, creating a streaky, hazy finish that washes away quickly. The ideal application uses minimal product—just enough to create a thin, even film that flashes within minutes. This ensures complete curing and maximum adhesion.

Environmental Conditions During Application

Applying sealant in direct sunlight, high humidity, or temperatures below 50°F dramatically reduces durability. Heat causes solvents to evaporate too quickly, preventing proper polymer flow and leveling. Cold temperatures slow cross-linking to the point that contamination settles into the film before it cures. Humidity introduces water molecules that interfere with polymer bonding. The sweet spot is 60-75°F with less than 60% humidity in a shaded, controlled environment.

Testing and Validating Sealant Durability Claims

Manufacturer claims often stem from idealized laboratory conditions. Understanding testing methodologies helps set realistic expectations.

Industry Standard Tests Explained

Look for products tested to ASTM D523 (gloss retention), ASTM G154 (accelerated weathering), and SAE J2527 (automotive exterior testing). These standardized methods measure how sealants perform under controlled UV exposure, temperature cycling, and chemical attack. Reputable manufacturers publish test data showing gloss retention percentages after 1000+ hours of accelerated weathering, which correlates to months or years of real-world exposure. Be wary of vague “tested to last” claims without specific methodology.

Real-World vs. Laboratory Conditions

Laboratory tests use perfect paint, controlled application, and ideal maintenance—conditions no daily driver experiences. Real-world durability typically runs 60-70% of laboratory claims due to factors like improper washing, environmental contamination, and minor paint defects. A sealant rated for 12 months in testing might deliver 7-9 months on a daily driver in moderate climates. Adjust expectations downward based on your specific use case and maintenance discipline.

Warranty and Guarantee Considerations

Many sealants come with performance guarantees, but the fine print reveals important limitations that affect real-world durability.

What Manufacturers Actually Cover

Most warranties cover product defects—like separation or premature failure due to formulation issues—but not application errors or environmental damage. Some premium brands offer performance guarantees that provide replacement product if you don’t achieve stated durability, but these require strict adherence to their preparation and application protocols, often including use of their entire product line. Document your process with photos if you plan to make a warranty claim.

Fine Print That Affects Durability Claims

Warranties often require annual inspection and reapplication of topper products to remain valid. They may exclude commercial vehicles, fleet use, or vehicles driven more than a certain mileage annually. Geographic restrictions are common—products warranted in mild climates may void coverage in areas with heavy road salt use. Read warranty terms before purchase to understand what maintenance obligations you’re accepting and what environmental factors might nullify coverage.

Future Innovations in Sealant Technology

The paint protection landscape continues evolving, with emerging technologies promising even greater durability and easier application.

Emerging Formulations on the Horizon

Self-healing sealants incorporating microcapsules that release fresh polymer when scratched are entering the market. Bio-based polymers derived from renewable sources are achieving synthetic-level performance while reducing environmental impact. Adaptive sealants that change their surface energy based on temperature and humidity promise better performance across climate extremes. While these technologies are still maturing, they signal a future where 18-24 month sealant durability may become standard for consumer-grade products.

Frequently Asked Questions

How long should I realistically expect a quality paint sealant to last on my daily driver?

In moderate climates with proper maintenance, expect 6-9 months from premium polymer sealants and 9-12 months from advanced SiO2 or graphene-enhanced formulas. Harsh winters, intense sun, or automated car washes can reduce this by 30-50%. The key is consistent pH-neutral washing and avoiding abrasive cleaning methods.

Can I apply a new sealant over an old one, or must I completely strip the previous layer?

You should never apply sealant over a failing or contaminated layer. Old sealant that’s still performing can serve as a foundation, but you must decontaminate thoroughly with iron remover and clay bar. If the old layer is showing water spotting or reduced beading, strip it completely using a paint-safe degreaser or polishing to ensure proper bonding of the new application.

Do graphene or SiO2-infused sealants really last longer than traditional polymer sealants?

Yes, the added ceramic or graphene components create a harder, more chemically resistant film that bonds more tenaciously to clear coat. However, the difference is incremental—perhaps 2-4 months additional durability—not revolutionary. The real benefit is enhanced resistance to water spotting and chemical etching, which maintains appearance longer even as hydrophobicity gradually decreases.

Will using a pressure washer damage my sealant or reduce its lifespan?

Proper pressure washing won’t harm quality sealants when using a 25-degree or wider nozzle held at least 12 inches from the surface. The film is designed to withstand water pressure far exceeding typical consumer-grade pressure washers. However, using narrow 0-degree tips or holding the nozzle too close can mechanically abrade the sealant, especially at edges and panel gaps where the film is thinner.

How does paint color affect sealant durability and performance?

Darker colors absorb more heat, subjecting the sealant to higher surface temperatures—often 30-50°F hotter than white or silver vehicles in direct sun. This thermal stress accelerates polymer degradation, potentially reducing durability by 15-20%. Dark paints also show sealant failure more obviously as water spotting and loss of gloss. If you own a black or dark blue vehicle, prioritize sealants with the highest temperature stability and UV protection ratings.

Is it worth applying multiple coats of sealant for extra durability?

Two properly applied coats can increase durability by 20-30% by ensuring complete coverage and building optimal film thickness. However, additional coats beyond two show diminishing returns and increase the risk of application errors. The key is allowing full curing between coats (24 hours) and keeping each layer microscopically thin. Three or more coats often create a soft, unstable film that fails prematurely through delamination.

Can sealant durability be improved by using a ceramic coating topper or maintenance spray?

Compatible SiO2 or graphene toppers can extend effective hydrophobicity and gloss by replenishing sacrificial ingredients that degrade. However, they must share similar chemistry with your base sealant. Using a ceramic topper on a basic acrylic sealant provides minimal benefit because the base layer lacks the structure to support the ceramic additives. For best results, use topper products from the same manufacturer or technology family, applying them quarterly at most.

What’s the best way to test if my sealant is still providing protection?

The water beading test is reliable but imperfect. Spray water on a horizontal panel—tight, tall beads indicate good hydrophobicity, while flat sheeting suggests degradation. More telling is the “bag test”: place a small plastic bag over your hand and gently rub the paint. If it feels slick and smooth, protection remains. If it feels grabby or rough, contaminants are adhering directly to the clear coat. Perform this test monthly after the 4-month mark to track degradation.

How do road salts and deicing chemicals specifically impact sealant durability?

Road salts are hygroscopic, meaning they attract and hold moisture against the paint surface, creating a concentrated electrolyte solution that can penetrate microscopic sealant imperfections. Magnesium chloride, increasingly common in deicers, is particularly aggressive, chemically attacking polymer bonds. Quality sealants with high fluorine content and dense cross-linking resist this penetration, but even the best formulations experience accelerated wear in salted environments, often requiring reapplication 2-3 months sooner than in mild climates.

Should I seal my paint before or after installing paint protection film (PPF) for maximum overall durability?

Always apply sealant after PPF installation. Paint protection film is designed to bond directly to clear coat, and sealant residue can interfere with adhesion, causing edges to lift. Once installed, seal the PPF itself—it benefits from UV protection and hydrophobicity just like paint. In fact, sealing PPF is crucial because the film’s polyurethane composition is more porous than clear coat and can stain more easily. Use a sealant specifically compatible with PPF to avoid discoloration or adhesion issues.