The difference between a profitable detailing operation and one that’s constantly chasing its tail often comes down to something as simple as how you buy your sealants. While weekend warriors debate which 16-ounce bottle performs best, professional detailers know that bulk sealants aren’t just a purchase—they’re a business strategy that directly impacts your bottom line, consistency, and client satisfaction. Whether you’re running a mobile unit or managing a multi-bay shop, understanding the nuances of bulk automotive sealants can transform your workflow from chaotic to clockwork.

But here’s the thing: not all bulk sealants are created equal, and the “best” choice depends on factors most product reviews never mention. Your local climate, application methods, client expectations, and even your shop’s storage capabilities should drive your decision more than flashy marketing claims. This guide cuts through the noise to focus on what actually matters when you’re investing in professional-grade protection products by the gallon.

Top 10 Bulk Sealants

Detailed Product Reviews

1. Dicor 501LSW-1 Epdm Self-Leveling Lap Sealant-10.3 Oz. Tube, White, 10.3 Fluid_Ounces (Packaging May Vary)

Overview: The Dicor 501LSW-1 is a specialized self-leveling lap sealant engineered specifically for RV roofing applications. This 10.3-ounce tube delivers a white, UV-stabilized formulation that creates professional-grade waterproof barriers on horizontal surfaces. Designed for compatibility with EPDM, TPO, and PVC membranes, it serves as an essential maintenance solution for RV owners seeking to prevent costly water intrusion damage.

What Makes It Stand Out: This sealant’s self-leveling property eliminates tooling, automatically creating a smooth, professional finish. Its sun-ray stabilization prevents degradation and discoloration common in standard caulks, ensuring your RV roof maintains its appearance. The formulation adheres tenaciously to diverse materials including aluminum, wood, fiberglass, and concrete, making it remarkably versatile beyond just membrane roofing applications.

Value for Money: At $8.49 per tube, this specialized RV product commands a modest premium over generic silicone caulk but delivers purpose-built performance. The targeted formulation prevents expensive water damage repairs, offering significant long-term savings. For RV owners, the price represents excellent value compared to professional application services, which can cost hundreds of dollars.

Strengths and Weaknesses:

- Strengths: Effortless self-leveling application; superior UV resistance prevents yellowing; broad material compatibility; won’t stain roofing materials; professional-grade durability; widely trusted in RV community.

- Weaknesses: Limited to horizontal surfaces only; single tube insufficient for large roof resealing projects; “packaging may vary” creates minor consistency concerns; requires clean, dry surface for optimal adhesion.

Bottom Line: This Dicor sealant is an indispensable tool for RV maintenance, delivering specialized performance that generic alternatives cannot match. Perfect for targeted repairs and touch-ups, it’s a must-have for any RV owner prioritizing roof integrity and leak prevention.

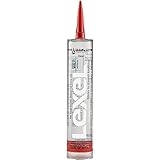

2. Sashco 13010 10.5oz Sealants Clear Lexel Adhesive Caulk, 10.5-Ounce (Pack of 12)

Overview: Sashco’s Lexel Adhesive Caulk offers exceptional versatility in a crystal-clear formulation. This 12-pack provides professional contractors and serious DIYers with a high-performance sealant that bonds to wet surfaces—a rare and valuable capability. Suitable for both interior and exterior applications, each 10.5-ounce tube delivers transparent sealing that disappears into the substrate for invisible repairs.

What Makes It Stand Out: The ability to adhere to wet surfaces sets Lexel apart from nearly every competitor, enabling emergency repairs during active leaks. Its superior clarity maintains a truly invisible bond line without the cloudiness or yellowing typical of clear silicone. The elastic polymer technology remains permanently flexible, accommodating significant joint movement without cracking or losing adhesion over time.

Value for Money: At $97.12 for twelve tubes ($8.09 each), this bulk pack offers substantial savings over individual purchase. The per-fluid-ounce cost of $0.77 positions it as a mid-tier professional product. For contractors, the volume pricing eliminates frequent reordering, while DIYers benefit from having premium sealant ready for any project, reducing last-minute hardware store runs.

Strengths and Weaknesses:

- Strengths: Bonds to wet surfaces; exceptional clarity; superior flexibility; interior/exterior versatility; professional-grade adhesion; bulk packaging economy; mold and mildew resistant.

- Weaknesses: High upfront investment impractical for small projects; clear finish may highlight application errors; requires mineral spirits for cleanup; 12-tube quantity may expire before casual users exhaust supply.

Bottom Line: Sashco Lexel is a professional’s secret weapon for challenging sealing scenarios. The wet-surface bonding capability alone justifies the investment. Best suited for contractors or homeowners with extensive project lists who value performance over cost-cutting.

3. 2025 Upgrade Repair Sealing Clay, Waterproof Sealant Mastic, Cement Crack Filler, Quick Mending Mud for Drain Connection, Wall Hole, Air Conditioning Hole Waterproof Seal Putty (6)

Overview: This innovative sealing clay represents a paradigm shift in quick-fix waterproofing solutions. The six-pack of moldable putty offers a tool-free approach to sealing cracks, pipe gaps, and penetration points around air conditioners and drains. Designed for both indoor and outdoor use, this air-drying mastic hardens within minutes of exposure, creating an immediate waterproof barrier without the mess of traditional caulk guns or mixing.

What Makes It Stand Out: The clay’s high plasticity allows custom shaping for any opening geometry—round, square, or irregular—eliminating the need for backer rods or complex preparation. Its instant-grab formula requires no curing time before resisting water exposure, making it ideal for emergency repairs during rain. The material’s dense composition ensures durability through temperature fluctuations without cracking or shrinking excessively.

Value for Money: At $13.99 for six units ($2.33 each), this product delivers exceptional economy for targeted repairs. Compared to liquid sealants requiring caulking guns and tooling time, the all-in-one convenience adds significant value. The multi-pack ensures you have material ready for multiple small projects throughout the home, from HVAC penetrations to plumbing connections.

Strengths and Weaknesses:

- Strengths: Tool-free application; moldable for custom fits; rapid air-dry hardening; excellent for irregular gaps; indoor/outdoor versatility; multi-pack value; minimal skill required; no waste from partial tubes.

- Weaknesses: Not suitable for large surface areas; aesthetic finish less refined than liquid sealants; may shrink slightly during curing; limited flexibility after hardening; not paintable; uncertain long-term UV stability.

Bottom Line: This sealing clay excels as a homeowner’s emergency repair kit staple. For quick, effective waterproofing of small penetrations without tools or expertise, it’s unmatched. Keep a pack handy for unexpected leaks and gaps, but use liquid sealants for visible, high-performance applications.

4. Dicor 501LSW-1 Self-Leveling Lap Sealant, 4 Pack

Overview: This four-pack bundles Dicor’s renowned self-leveling lap sealant for RV roofing projects requiring more extensive coverage. Each 10.3-ounce tube delivers the same white, UV-stabilized formula designed to create secondary seals along roof edges, vents, and screw heads. The bulk packaging addresses the needs of multi-unit RV owners or professional mobile technicians who require consistent, reliable performance across larger jobs.

What Makes It Stand Out: The four-pack ensures consistent color matching across large roof surfaces—a critical factor for RV aesthetics and resale value. The self-leveling technology maintains professional-grade results without tooling, while the bulk quantity eliminates mid-project supply runs. The two-year manufacturer expiration date provides clear shelf-life guidance for inventory management, a professional-grade consideration often missing in consumer products.

Value for Money: At $41.99 for four tubes ($10.50 per tube), this pack carries a 24% premium over individual purchases. However, the convenience of bulk buying and ensured batch consistency justifies the cost for serious projects. For professional RV technicians, the time saved sourcing materials offsets the price difference, while enthusiasts appreciate having backup tubes for future maintenance without emergency hardware store trips.

Strengths and Weaknesses:

- Strengths: Bulk convenience; color consistency across batch; proven UV stability; self-leveling ease; versatile substrate adhesion; clear expiration dating; trusted brand reputation.

- Weaknesses: Higher per-unit cost than singles; two-year expiration requires planning; still limited to horizontal applications; significant upfront investment for casual users; may harden in tube if stored improperly.

Bottom Line: This four-pack serves RV enthusiasts and professionals perfectly. If you’re resealing an entire roof or maintaining multiple units, the convenience outweighs the modest premium. For one-time small repairs, purchase individually. The batch consistency alone makes it worthwhile for visible roof work.

5. Sashco 14004 Gallon Clear Roof Sealant

Overview: Sashco’s gallon-sized clear roof sealant delivers professional-grade waterproofing in bulk quantity for extensive projects. Packaged in a manageable container, this clear formulation covers large roof areas economically. While product details are minimal in the listing, the gallon size suggests contractor-focused application for comprehensive roof sealing rather than targeted repairs, making it ideal for full roof restorations.

What Makes It Stand Out: The gallon volume provides exceptional coverage for entire roof systems, eliminating the need for dozens of individual tubes. Its clear finish preserves the original roof appearance while delivering protective waterproofing. The substantial package weight and US origin indicate a high-solids formulation designed for professional application with brushes or rollers, ensuring thick, durable protection in fewer coats.

Value for Money: At $69.02 per gallon ($0.54 per fluid ounce), this product offers substantial per-ounce savings compared to tube sealants costing nearly 50% more per ounce. For projects exceeding 500 square feet, the economy becomes compelling. The investment makes sense for whole-roof applications but proves impractical for small repairs where material waste and cleanup would negate savings.

Strengths and Weaknesses:

- Strengths: Exceptional coverage area; economical per-unit cost; clear aesthetic preservation; professional-grade volume; suitable for large surface sealing; reduces packaging waste.

- Weaknesses: Requires brushes/rollers for application; impractical for small repairs; heavy container handling challenges; minimal product specifications; potential waste for occasional users; unclear substrate compatibility details.

Bottom Line: This gallon sealant excels for comprehensive roof projects. Contractors and homeowners sealing entire roofs will find the volume and value compelling. For minor repairs, stick with tube-based alternatives. Ensure you have proper application equipment and a large enough project to justify the quantity before purchasing.

6. GE Advanced Silicone Caulk for Kitchen & Bathroom, Clear, 2.8 fl oz Tube, 1 Pack - 100% Waterproof Silicone Sealant, 5X Stronger Adhesion, Shrink & Crack Proof

Overview:

This GE Advanced Silicone Caulk is a specialized sealant designed for high-moisture environments like kitchens and bathrooms. The clear, 2.8-ounce tube delivers a 100% silicone formula that promises ultimate water protection. Engineered for durability, it maintains flexibility while creating a waterproof barrier around sinks, tubs, showers, and backsplashes. The compact size makes it ideal for small repair jobs and touch-ups rather than large-scale renovations.

What Makes It Stand Out:

The 30-minute water-ready feature sets this caulk apart from standard options that typically require 24-48 hours. This rapid curing time minimizes downtime in essential areas like bathrooms. GE’s claim of 5X stronger adhesion provides confidence for long-term performance, while the shrink- and crack-proof formulation withstands temperature fluctuations without failing. Its compatibility with most common building materials—including tile, glass, metal, and granite—makes it remarkably versatile for household applications.

Value for Money:

At $6.17 for a 2.8-ounce tube, this premium caulk costs approximately $2.20 per ounce, positioning it in the mid-to-high range. While pricier than basic acrylic caulks, its professional-grade performance and rapid cure time justify the premium for targeted repairs. For homeowners tackling small projects, the reliability and reduced wait time offer excellent return on investment compared to cheaper alternatives that may fail prematurely.

Strengths and Weaknesses:

Strengths: Extremely fast water exposure readiness; superior flexibility and adhesion; clear formula blends seamlessly; excellent mold and mildew resistance; compatible with diverse surfaces.

Weaknesses: Small tube size limits large projects; requires caulk gun (not included); strong odor during application; higher cost per ounce than basic sealants; surface prep is critical for optimal bonding.

Bottom Line:

The GE Advanced Silicone Caulk is an outstanding choice for homeowners needing quick, reliable sealing in wet areas. Its rapid curing and durable performance make it worth the slight premium for bathroom and kitchen repairs where time and longevity matter most.

7. Slime 10193 Tire and Tube Sealant Puncture Repair Sealant, 2-in-1, Premium, Prevent and Repair, Suitable for Non-Highway Tires and Tubes, Non-Toxic, Eco-Friendly, 16oz Bottle

Overview:

Slime’s 2-in-1 Tire and Tube Sealant is a preventative and emergency repair solution for non-highway tires and tubes. This 16-ounce bottle contains a fibrous sealant that continuously coats the interior of tires, automatically seeking and sealing punctures before they cause flats. Designed for bicycles, lawn mowers, wheelbarrows, and small trailers, it provides two years of continuous protection, making it essential equipment for anyone relying on tube-based or off-road tires.

What Makes It Stand Out:

The dual-action formula both prevents and repairs punctures up to 1/4-inch in tires and 1/8-inch in tubes without requiring removal of the wheel. Its eco-friendly, non-toxic composition eliminates environmental and safety concerns associated with chemical sealants. The included valve core removal tool and installation hose make DIY application straightforward. The patented sealing mechanism uses the tire’s own air pressure to force fibers into punctures, creating a flexible, permanent plug.

Value for Money:

At $11.98 for 16 ounces, this sealant costs less than a single replacement inner tube while protecting multiple tires for two years. For families with several bikes or property owners with lawn equipment, the cost savings from avoided flats and downtime quickly outweigh the initial investment. Compared to professional tire repairs or constant tube replacements, it delivers exceptional long-term value.

Strengths and Weaknesses:

Strengths: Prevents flats before they happen; non-toxic and environmentally safe; easy installation with included tools; works on wide variety of small vehicles; effective for two years; seals while you ride.

Weaknesses: Not suitable for highway vehicle tires; limited to 1/4" punctures; can create slight wheel imbalance; messy if spilled; requires complete drying period before effectiveness.

Bottom Line:

Slime’s 2-in-1 Sealant is a must-have for cyclists and homeowners with lawn equipment. Its preventative protection and eco-friendly formula make it a smart, cost-effective investment that virtually eliminates flat tire frustrations for non-highway applications.

8. Xtra-Seal - Bead Sealer Flammable 32Oz (TI250)

Overview:

The Xtra-Seal Bead Sealer is a professional-grade tire bead sealing compound designed for automotive and commercial applications. This 32-ounce container provides a flammable, fast-drying solution that seals leaks between the tire bead and wheel rim. Primarily used by tire technicians and automotive professionals, it addresses air loss issues that standard plug repairs cannot fix, particularly on older or corroded wheels where the tire bead fails to maintain an airtight seal.

What Makes It Stand Out:

Formulated specifically for professional use, this bead sealer creates an aggressive bond that withstands the stresses of tire mounting and inflation. Its flammable nature indicates a solvent-based formula that dries rapidly, reducing service time in busy shops. The large 32-ounce size caters to high-volume users, while the specialized application brush (typically included) allows precise coating of wheel rims. Unlike multi-purpose sealants, this product focuses exclusively on bead seating problems.

Value for Money:

Priced at $16.89 for 32 ounces, this professional product offers reasonable value for shops but may be excessive for casual users. At approximately $0.53 per ounce, it’s cost-effective for technicians who regularly service problematic tires. DIY enthusiasts may find the quantity and specialized nature less economical compared to smaller consumer alternatives, though its effectiveness justifies the cost for those dealing with chronic bead leaks.

Strengths and Weaknesses:

Strengths: Professional-strength formulation; large quantity for frequent use; fast-drying flammable formula; specifically targets bead leaks; reliable for corroded rims; trusted by technicians.

Weaknesses: Flammable nature requires careful handling; not for consumer tire repairs; vague product descriptions lack detail; requires professional application technique; limited to bead sealing only.

Bottom Line:

Xtra-Seal Bead Sealer is strictly for automotive professionals or serious DIY mechanics dealing with persistent bead leaks. Its specialized, flammable formula demands careful handling but delivers reliable results that general-purpose sealants cannot match in professional settings.

9. Waterproof Sealant 70oz Clear, TUFINEIN Transparent Waterproof Coating Water-Based Invisible Agent Roofs, Walls, Garden, Terraces Indoor & Outdoor

Overview:

TUFINEIN’s Transparent Waterproof Coating is a water-based, invisible sealant designed for large-scale interior and exterior applications. This substantial 70-ounce container creates a clear, flexible membrane that protects surfaces from water infiltration without altering their appearance. Suitable for roofs, walls, basements, gardens, and terraces, it forms a temperature-resistant barrier on concrete, wood, metal, ceramic, and brick surfaces, making it ideal for aesthetic preservation projects.

What Makes It Stand Out:

The invisible finish maintains the original look of treated surfaces, a crucial advantage for decorative brick, stone, or wood applications. Its water-based formula offers easier cleanup and lower VOCs than solvent alternatives. The product’s versatility spans indoor and outdoor use, from bathroom waterproofing to roof protection. Temperature resistance ensures performance across climate extremes, while the large 70-ounce size provides coverage for approximately 14 square feet per kilogram with 2-3 coats.

Value for Money:

At $35.99 for 70 ounces ($0.51 per ounce), this sealant presents solid value for extensive projects. While the initial cost exceeds smaller tubes, the coverage area and multi-surface capability reduce the need for multiple specialized products. For homeowners protecting visible surfaces where appearance matters, the transparent finish eliminates the cost and labor of cosmetic touch-ups required by pigmented sealants.

Strengths and Weaknesses:

Strengths: Completely transparent finish; large quantity for big projects; water-based and low odor; extreme temperature resistance; multi-surface versatility; suitable for indoor/outdoor use.

Weaknesses: Requires 2-3 coats for effectiveness; 24-hour drying time between coats; needs specific application conditions (dry, >41°F); limited to 14 sq ft coverage per kg; application learning curve for optimal results.

Bottom Line:

TUFINEIN’s Waterproof Sealant excels for projects where preserving appearance is paramount. While the multi-coat process demands patience, its invisible protection and versatility make it a worthwhile investment for comprehensive home waterproofing needs.

10. 6-Pack New Type White Waterproof Sealant Mastic, Repair Sealing Clay, Quick Mending Mud for Drain Connection, Wall Hole, Air Conditioning Hole Waterproof Seal Putty

Overview:

This six-pack of white waterproof sealant mastic offers a unique clay-based approach to sealing holes, gaps, and connections around the home. Each package contains pliable, hand-moldable putty that requires no tools or applicators—simply shape and press into place. Designed for drain connections, wall penetrations, and air conditioning line holes, it creates a durable, waterproof barrier after 2-3 days of curing. The clay formulation also blocks odors and provides thermal insulation, making it a multi-functional repair solution.

What Makes It Stand Out:

The tool-free application distinguishes this product from traditional caulks and sealants. Its soft, flexible consistency allows it to be pressed into irregularly shaped gaps and voids that rigid materials cannot fill effectively. The odor-blocking capability addresses issues around drains and sewage lines, while the insulating properties add value for HVAC applications. The convenient packaging lets users open only what’s needed, reducing waste on small repairs.

Value for Money:

At $10.99 for a six-pack ($1.83 per unit), this mastic delivers exceptional value for homeowners needing multiple small repairs. The cost per repair is significantly lower than hiring professionals or buying separate specialized products for each application. While traditional putties may be cheaper, the convenience, waterproofing, and multi-purpose nature justify the modest premium.

Strengths and Weaknesses:

Strengths: No tools required for application; excellent for irregular gaps; blocks odors and insulates; convenient multi-pack packaging; waterproof when cured; versatile household applications.

Weaknesses: Extended drying time (3-5 days before water exposure); cannot be used on wet surfaces; not suitable for high-pressure plumbing; confusing package description; less durable than epoxy alternatives.

Bottom Line:

This moldable sealant mastic is perfect for DIYers seeking an easy, no-mess solution for common household holes and gaps. While patience is required for curing, its versatility and user-friendly application make it an excellent addition to any home maintenance toolkit.

Why Professional Detailers Choose Bulk Sealants

The math is simple but often overlooked. A professional applying sealant to 5-10 vehicles daily will burn through consumer-sized containers in a week, creating constant reordering headaches and price volatility. Bulk purchasing stabilizes your cost-per-vehicle, reduces packaging waste, and ensures batch consistency that your repeat customers will notice. More importantly, it signals to clients that you’re operating at a professional level—not just buying off the shelf and marking it up.

Beyond economics, bulk systems give you control over dilution ratios and application methods that pre-packaged products don’t. You can adjust concentration for specific paint types, climate conditions, or client budgets without switching products entirely. This flexibility becomes your competitive edge, especially when you’re building maintenance packages that keep customers returning every quarter.

Decoding Sealant Chemistry for Informed Decisions

The SiO2 Revolution and Beyond

Silicon dioxide-based sealants revolutionized paint protection, but the technology has splintered into multiple categories. True ceramic-infused sealants contain suspended SiO2 particles that form a crystalline lattice as they cure, creating measurable hardness. However, concentration matters more than marketing—anything below 15% SiO2 content offers minimal advantage over traditional polymer sealants. Professional-grade bulk options typically range from 20-35% concentration, with the sweet spot for most operations landing around 25%.

The carrier system is equally critical. Water-based formulas offer safer handling and lower VOCs but may sacrifice durability in extreme climates. Solvent-based carriers provide better bonding in cold weather but require stricter safety protocols. Your choice should align with your shop’s ventilation capabilities and local environmental regulations.

Polymer-Based Formulations for Specific Climates

Polymer sealants aren’t obsolete—they’re specialized. High-quality polymer blends excel in regions with extreme temperature fluctuations because they maintain flexibility better than rigid ceramic coatings. They bond through cross-linking rather than crystallization, which means they can expand and contract with the paint surface. For shops in the desert Southwest or northern states with brutal winters, a premium polymer sealant might outperform ceramics in real-world longevity.

Look for polymers with Teflon or acrylic co-polymers in the formulation. These create slicker surfaces and better chemical resistance than basic polymer blends. The key is identifying whether the product uses linear or cross-linked polymers—cross-linked versions offer 3-4 times the durability but may require longer cure times.

Hybrid Technologies: Getting the Best of Both Worlds

The latest generation of bulk sealants combines SiO2 particles with polymer resins, attempting to capture ceramic hardness with polymer flexibility. These hybrids typically apply like polymers but cure with ceramic-like properties. The trick is understanding the ratio: products with 70% polymer and 30% ceramic will behave more like traditional sealants, while a 50/50 split offers genuine ceramic benefits with easier application.

For most professional operations, hybrids represent the best bulk investment because they reduce application errors while delivering results clients can see. They’re more forgiving with temperature variations and don’t require the paint-perfect surface preparation that pure ceramics demand.

Performance Metrics That Separate Pros from Amateurs

Real-World Durability vs Marketing Claims

That “12-month protection” claim on the label? It was likely tested in a climate-controlled lab on perfectly prepped panels. In professional use, durability depends on maintenance habits, environmental exposure, and application thickness. A quality bulk sealant should provide 6-8 months of visible water beading and gloss enhancement on daily drivers, with 4-6 months on vehicles exposed to harsh conditions.

Track your own data. Measure how many weeks until water behavior changes, when gloss drops 10% on your meter, and how chemical stains appear. This creates a realistic timeline you can communicate to clients and helps you calculate true value per application.

Hydrophobicity: Contact Angles and Water Behavior

Water beading looks great in photos, but contact angle measurements tell the real story. Premium bulk sealants should achieve 110-120 degree contact angles initially. More importantly, they should maintain angles above 90 degrees for at least half their stated lifespan. Anything lower and you’re essentially selling glorified wax.

Watch how water sheets off horizontal panels versus vertical surfaces. A sealant that beads beautifully on a hood but sheets poorly on doors indicates uneven curing or formulation issues. Consistent behavior across all panels is your quality control check.

Gloss Meters and Measurable Shine

Professional detailers should invest in a gloss meter. It’s not just for marketing—it’s for quality control. A good bulk sealant will increase gloss readings by 15-25 points on a properly corrected surface. Track these numbers for each vehicle and build a database. When clients question your pricing, show them the data. More importantly, use gloss readings to identify when sealants are degrading and maintenance is due.

Chemical Resistance in Harsh Environments

Your sealant is the sacrificial layer between bird droppings, bug guts, and your client’s clear coat. Test bulk options by applying them to sample panels and exposing them to common contaminants: brake fluid, gasoline, bird lime simulant, and tree sap. A professional-grade sealant should resist etching for at least 4 hours, giving clients time to wash off contaminants before damage occurs.

Pay special attention to acid rain resistance if you’re in an urban area. pH 4-5 acidity is common in many regions and will degrade low-quality sealants within weeks.

Application Science: Methods That Maximize Efficiency

Spray, Wipe, or Machine: Workflow Optimization

Bulk sealants accommodate multiple application methods, but your choice affects both results and labor costs. Spray-and-wipe methods work fastest for full vehicles but require careful flash time management to avoid high spots. Machine application with a soft foam pad ensures even coverage but adds 15-20 minutes per vehicle. The professional approach? Use spray methods for maintenance coats and machine application for initial treatments.

Dilution ratios are your secret weapon. Most bulk concentrates can be diluted 1:1 to 3:1 with distilled water for different purposes. A 1:1 ratio gives maximum durability for high-end clients, while 3:1 creates an economical maintenance topper that still outperforms retail spray sealants.

Surface Prep: The Non-Negotiable Foundation

Even the best bulk sealant will fail on improperly prepped paint. The professional standard is decontamination wash, iron remover, clay treatment, and at least a one-step polish. Skipping any step reduces sealant bonding by 30-50%. For new cars, always clay—rail dust and factory contaminants are universal.

Paint correction before sealing isn’t optional; it’s part of the service. A sealant applied to swirled paint locks in that damage visually. Your bulk sealant should enhance perfection, not mask mediocrity.

Flash Times and Curing Windows

Every sealant has an optimal flash time—the period when solvents evaporate but the product remains workable. Too early and you remove the active ingredients; too late and you’re fighting a sticky residue. Professional bulk sealants typically flash in 30-90 seconds depending on temperature and humidity. Use a timer, not guesswork.

Curing is different from flashing. Most sealants require 12-24 hours before water exposure and 7 days for full hardness. Communicate this clearly. Offer clients a “curing care sheet” that explains when they can wash, when protection is fully active, and what to avoid during the first week.

Layering Strategies for Custom Protection

Smart professionals don’t just apply one coat—they build protection systems. A common strategy: polymer sealant base layer for flexibility, followed by SiO2 sealant for hardness, topped with a spray sealant for slickness. This triple-layer approach can extend durability by 40-60% while creating a deeper gloss.

Never layer the same product multiple times in one session. Wait 12-24 hours between coats of similar chemistry to allow proper cross-linking. Layering too quickly creates a soft, easily removed coating that wastes product and your labor.

Environmental Factors That Make or Break Results

Temperature Sweet Spots for Application

Most bulk sealants apply best between 60-80°F (15-27°C). Below 55°F, cure times double and bonding suffers. Above 85°F, solvents flash too quickly, causing high spots and streaking. If you’re mobile, carry a digital thermometer and schedule applications accordingly. Shop-based operations should invest in climate control—it’s cheaper than redoing jobs.

Some advanced formulas work in broader ranges, but they command premium prices. Calculate whether the upcharge offsets the convenience of all-weather application for your specific business model.

Humidity’s Hidden Impact on Curing

High humidity (above 70%) accelerates water-based sealant curing but can cause solvent-based products to blush or cure unevenly. Low humidity (below 30%) extends flash times and may require adjusted application techniques. Professional shops in coastal areas should prioritize humidity-resistant formulations, while desert operations need products with slower evaporation rates.

Use a hygrometer in your workspace. When humidity spikes, adjust your technique: work smaller sections, use less product, or switch to a machine application for more controlled coverage.

Indoor vs Outdoor Application Protocols

Mobile detailers face unique challenges. Direct sunlight, wind, and airborne contaminants ruin sealant applications. If you must work outdoors, schedule for early morning or late afternoon, use wind screens, and apply in 2x2 foot sections. Always carry a canopy for critical stages.

Indoor bays aren’t automatically better. Poor lighting hides high spots and streaking. Invest in LED shop lights with 5000K color temperature—they reveal application flaws before the client does.

Packaging and Dispensing: The Logistics of Bulk Products

Container Sizes and Material Compatibility

Bulk sealants typically come in 1-gallon, 5-gallon, or 55-gallon drums. One-gallon containers are manageable for mobile operations but require frequent reordering. Five-gallon pails offer the best balance for most shops, providing 150-200 vehicle applications per container. Fifty-five-gallon drums deliver maximum savings but require dedicated storage and pump systems.

Check container material. HDPE plastic is standard, but some aggressive solvent-based formulas can leach plasticizers over time, contaminating the product. Ask suppliers about compatibility and request samples in the actual bulk container before committing to large orders.

Pump Systems for Precision and Waste Reduction

Pouring directly from a 5-gallon pail wastes product through spills and over-pouring. Professional pump systems dispense measured amounts—typically 1-ounce per stroke—giving you consistent costing and reducing waste by 15-20%. Airless pumps prevent product contamination and oxidation, extending shelf life of opened containers.

Install pumps on dedicated sealant containers. The $150-200 investment pays for itself within two months through reduced waste and faster dispensing. Label each pump with the product name and dilution ratio to prevent cross-contamination.

Labeling and Batch Tracking for Quality Control

Every bulk container arrives with a batch number. Record it in a logbook along with the opening date and performance notes. If you notice application issues or client complaints spike, batch tracking helps identify whether you received a bad lot. Reputable suppliers will replace defective batches, but only if you can provide batch numbers.

Create secondary labels for your diluted spray bottles. Include product name, dilution ratio, date mixed, and initials of who mixed it. This prevents confusion and maintains consistency when multiple employees work on vehicles.

Cost Management Strategies for Sustainable Profitability

Calculating True Per-Vehicle Cost

Don’t divide container price by estimated applications. Factor in waste (5-10% is realistic), labor time for application, and the cost of associated materials (applicators, pads, PPE). A $300 5-gallon sealant that covers 150 vehicles might cost $2.30 per vehicle in product alone, but when you add 20 minutes of labor at your shop rate, the true cost could be $25-35 per application.

Track actual usage, not theoretical coverage. Weigh your container weekly and divide by vehicles serviced. This real-world data helps you price services accurately and identifies employees who need retraining on proper application techniques.

Pricing Your Services Competitively

Sealant application shouldn’t be a loss leader. Price for 60-70% gross margin minimum. If your true cost is $30 per vehicle, charge $85-100 for the service. This covers product, labor, overhead, and profit. Clients comparing your professional service to a $15 DIY bottle don’t understand the value of proper prep, application expertise, and guaranteed results.

Create tiered packages: “Maintenance Sealant” at 3:1 dilution for economy clients, “Premium Protection” at 1:1 for luxury vehicles, and “Multi-Layer System” for your highest-paying customers. This maximizes the value of your bulk purchase across different market segments.

Inventory Management to Prevent Waste

Sealants have shelf lives. Unopened, most last 12-24 months. Opened, they typically degrade within 6-12 months depending on storage conditions. Rotate stock like a grocery store: first in, first out. Never order more than you can use within 80% of the product’s opened shelf life.

Monitor seasonal demand. You might use 30% more sealant during spring prep season and fall protection months. Adjust ordering cycles accordingly to avoid emergency purchases of expensive small containers when you run out.

Client Communication and Expectation Management

Translating Technical Benefits for Customers

Clients don’t care about SiO2 percentages or contact angles. They care that their car stays cleaner between washes, bird droppings don’t etch the paint, and they get compliments at cars and coffee. Translate technical features into emotional benefits: “This creates a surface so slick that dirt has trouble sticking, so your weekly wash takes half the time.”

Use visual demonstrations. Show water behavior on treated versus untreated panels. Let clients feel the difference with a clean microfiber. These tangible experiences justify your pricing more effectively than technical jargon.

Setting Realistic Protection Timelines

Be honest about longevity. Tell clients “This will maintain its best performance for 6 months, then gradually diminish over the following 6 months.” Under-promise and over-deliver. When their sealant is still beading at 8 months, you’ve created a loyal customer. Over-promise and you’ll spend time on warranty claims and reputation repair.

Provide a written maintenance schedule. Specify when they should return for a maintenance topper, what wash methods to use, and what products to avoid. This positions you as a consultant, not just a service provider.

Building Maintenance Program Retention

Sealants aren’t one-and-done services—they’re the foundation of recurring revenue. Structure maintenance packages: “Initial application plus three maintenance treatments over 12 months for $X.” This locks in clients and ensures you’re reapplying before protection fails, maintaining your reputation.

Track each client’s service date in a CRM system. Send reminder emails at 5 months: “Your sealant is performing great! Let’s schedule your maintenance treatment to keep that protection strong.” Proactive communication prevents clients from shopping around.

Common Pitfalls That Cost You Money

Over-Application and Product Waste

More product doesn’t equal more protection—it equals wasted money and difficult removal. Most sealants achieve maximum protection at 1-2 microns thickness. Applying extra coats beyond the manufacturer’s recommendation adds minimal durability while increasing cure time and high spot risk.

Train employees on proper coverage rates. A typical sedan needs 1-1.5 ounces of concentrated sealant. Use measuring pumps and track usage per vehicle. If one technician consistently uses 30% more product, they’re either over-applying or spilling—both fixable problems.

Incompatible Product Layering

Layering a polymer sealant over a ceramic coating can work; the reverse often doesn’t. Ceramics need to bond directly to the paint surface. Applying them over polymers creates a weak interface that fails prematurely. Always check compatibility charts from manufacturers, and when in doubt, stick to one chemistry family per vehicle.

The same applies to maintenance products. Using a silicone-heavy quick detailer on a ceramic sealant can mask its hydrophobic properties, making clients think the sealant failed when it’s just contamination. Specify approved maintenance products for each sealant type.

Improper Storage and Contamination

Storing bulk sealants in direct sunlight or near heat sources accelerates degradation. Leaving containers open introduces moisture and airborne contaminants that cause premature curing inside the container. Always seal containers immediately after dispensing, store in a climate-controlled area between 60-75°F, and use desiccant packs in partially used containers.

Never return unused product to the bulk container. This introduces contaminants and can start a curing reaction that ruins the entire supply. Mix only what you need for each vehicle.

Safety, Compliance, and Professional Standards

VOC Regulations by Region

Volatile Organic Compound limits vary dramatically by state and municipality. California’s CARB standards are the strictest, limiting automotive sealants to 7% VOC by weight. Many bulk sealants formulated for national distribution exceed this limit. Using non-compliant products can result in fines starting at $1,000 per violation.

Before ordering bulk, verify the product’s VOC content and your local regulations. Reputable suppliers provide VOC data sheets. When in doubt, choose water-based formulas—they’re universally compliant but may require adjusted application techniques.

Essential PPE for Daily Use

Even “eco-friendly” sealants contain chemicals that require protection. Nitrile gloves prevent skin absorption of solvents. Safety glasses protect against splashes during dispensing. For solvent-based products, use a half-face respirator with organic vapor cartridges when applying in enclosed spaces.

Keep PPE readily available. A dispenser near your sealant station reminds employees to gear up. Replace gloves every 2-3 vehicles or when they become contaminated. A $0.20 glove is cheaper than a dermatitis claim.

SDS Management and Shop Documentation

OSHA requires Safety Data Sheets for all chemical products to be accessible to employees. Create a binder or digital file with SDS for every bulk sealant you use. Update it when you switch products or receive new batches. During inspections, this simple documentation prevents citations.

Train employees on SDS sections 2 (hazards), 4 (first aid), and 8 (exposure controls). A 15-minute monthly safety meeting reviewing sealant SDS information keeps everyone informed and demonstrates due diligence if incidents occur.

Frequently Asked Questions

How long do bulk sealants really last compared to consumer versions?

Professional bulk sealants typically contain higher concentrations of active ingredients, so they last 30-50% longer than consumer equivalents when applied correctly. Real-world durability ranges from 6-12 months depending on the formulation, climate, and maintenance. Consumer products often quote idealized lab conditions; bulk products purchased by professionals should come with realistic expectations based on field testing.

Can I mix different sealants together to create a custom blend?

Never mix different sealant chemistries directly. Combining SiO2 and polymer sealants in the same bottle causes unpredictable curing and can create a useless gel. Instead, layer them properly: apply one chemistry as a base, let it cure fully, then apply the second as a topper. This achieves hybrid performance without chemical incompatibility issues.

What’s the ideal temperature range for applying sealants?

Most bulk sealants perform optimally between 60-80°F with low wind and moderate humidity. However, professional-grade formulas designed for mobile operations often work from 50-90°F. Below 50°F, cure times extend dramatically and bonding suffers. Above 90°F, flashing becomes uncontrollable. Always check the technical data sheet for your specific product’s range.

How do I know if a bulk sealant is compatible with my client’s existing coating?

Perform a test spot in an inconspicuous area. Apply the sealant to a 1x1 foot section, let it cure fully, and observe for 24 hours. Look for beading changes, discoloration, or surface texture differences. When in doubt, contact the sealant manufacturer with the existing coating’s name—they maintain compatibility databases. As a general rule, you can apply polymer sealants over ceramics, but not vice versa.

What’s the shelf life of an opened 5-gallon container?

Opened bulk sealants typically last 6-12 months if stored properly: sealed tightly, kept between 60-75°F, and protected from direct sunlight. Water-based formulas last longer than solvent-based ones. Always record the opening date on the container. If the sealant thickens, changes color, or develops an odor, it’s compromised. Unopened containers generally last 12-24 months from manufacture date.

Do I really need a pump system, or can I pour directly?

While you can pour directly, pump systems pay for themselves within 60-90 days through reduced waste and consistent dispensing. They prevent spills, measure exact amounts for cost tracking, and minimize air exposure that degrades the product. For 1-gallon containers, a simple measuring cup works. For 5-gallon pails and larger, pumps are essential professional equipment.

How do I price sealant application without scaring away customers?

Focus on value, not cost. Explain that professional application includes paint decontamination, surface preparation, and proper curing management that DIY can’t replicate. Break pricing into tiers: basic protection ($75-125), premium ($150-200), and multi-layer systems ($250-350). Show clients water behavior demos and provide written durability guarantees. The customers who appreciate quality will pay professional rates.

Are VOC regulations different for bulk products versus consumer sizes?

No—VOC content is regulated by the chemical formulation, not package size. However, bulk purchases often involve larger total quantities, increasing your regulatory exposure if you’re non-compliant. Some regions require permits for storing certain volumes of VOC-containing products. Always verify local fire code and air quality regulations when ordering drums larger than 5 gallons.

Can I apply sealants outdoors, or do I need a climate-controlled bay?

You can apply sealants outdoors, but results suffer. Wind introduces contaminants, sunlight causes uneven flashing, and temperature swings affect cure rates. If outdoor application is unavoidable, use portable canopies, work during stable weather windows (early morning), and apply in smaller sections. For consistent, warranty-worthy results, climate-controlled bays are worth the investment.

How do I train new employees on proper application techniques?

Create a standard operating procedure document with photos showing correct product amount, application pattern, and removal technique. Have new hires practice on old hoods or scrap panels before touching client vehicles. Use a gloss meter and water behavior tests to verify their work. Pair them with experienced techs for the first 10-15 applications. Track their product usage—over-application is the most common rookie mistake.