If you’ve ever watched water bead up and roll off a freshly detailed car with mesmerizing precision, you’ve witnessed the magic of a quality paint sealant. While traditional paste waxes have their place in automotive history, spray paint sealants have revolutionized how enthusiasts and professionals protect vehicle finishes. These innovative formulations deliver synthetic protection that can last months—not weeks—while cutting application time down to a fraction of what conventional methods demand.

But not all spray sealants are created equal. The market is flooded with options promising mirror-like gloss, extreme hydrophobicity, and year-long durability. Understanding the science behind these claims, the features that actually matter, and the application techniques that make or break performance is essential for anyone serious about paint protection. Whether you’re a weekend warrior looking to elevate your car care game or a seasoned detailer evaluating new technologies, this comprehensive guide will equip you with the knowledge to make informed decisions without getting lost in marketing hype.

Top 10 Paint Sealant Spray

Detailed Product Reviews

1. Rust-Oleum 249859 Painter’s Touch 2X Ultra Cover Spray Paint, Semi-Gloss Clear , 12 Ounce (Pack of 1)

Overview: Rust-Oleum’s Painter’s Touch 2X Ultra Cover in Semi-Gloss Clear delivers a versatile protective coating for diverse surfaces. This oil-based spray paint works on wood, plastic, metal, masonry, and ceramic, making it ideal for both indoor and outdoor projects. The semi-gloss finish offers a subtle shine that enhances surfaces without overwhelming them.

What Makes It Stand Out: The semi-gloss finish strikes a perfect balance between flat and high-gloss, providing a soft sheen that masks minor imperfections while adding depth. The 2X Ultra Cover technology promises double the coverage per can compared to standard sprays, while the oil-based formula ensures superior chip resistance and durability for long-lasting protection.

Value for Money: At $6.19 for 12 ounces ($0.52 per ounce), this represents excellent value for a multi-surface protective coating. The 12 square foot coverage per can is competitive, and the durability means fewer reapplications. Compared to buying separate primers and topcoats, this all-in-one solution saves both money and time.

Strengths and Weaknesses: Strengths include fast 20-minute drying time, excellent adhesion to multiple substrates, and strong durability. The semi-gloss finish is versatile for most projects. Weaknesses include strong fumes requiring ventilation, potential yellowing over time on light surfaces, and the need for careful application to avoid drips on vertical surfaces.

Bottom Line: This is a reliable workhorse for DIYers seeking durable protection with a subtle sheen. It performs best on furniture, décor, and outdoor items where moderate shine is desirable. For the price, it’s hard to beat for general-purpose clear coating needs.

2. Rust-Oleum 334029 Painter’s Touch 2X Ultra Cover Spray Paint, 12 oz, Gloss Clear

Overview: Rust-Oleum’s Painter’s Touch 2X Ultra Cover in Gloss Clear provides a high-shine protective finish for virtually any surface. This versatile oil-based spray adheres to wood, plastic, metal, masonry, and ceramic, offering robust protection for both interior and exterior applications. The gloss finish creates a fresh, polished appearance that revitalizes tired surfaces.

What Makes It Stand Out: The high-gloss finish delivers a wet-look shine that makes colors pop and surfaces appear new. The 2X coverage technology maximizes efficiency, while the oil-based chemistry provides exceptional chip resistance. This formula goes on smoothly, self-leveling to minimize imperfections and create a professional-looking glass-like surface.

Value for Money: Priced identically to its semi-gloss and matte siblings at $6.19 per can, this offers the same excellent value proposition. The 12 square foot coverage and durable protection mean your investment lasts. For projects requiring a glossy finish, it eliminates the need for separate clear coats, saving money on additional products.

Strengths and Weaknesses: Strengths include outstanding durability, rapid 20-minute dry time, and superior surface protection. The gloss finish is highly washable and stain-resistant. Weaknesses are the strong odor requiring proper ventilation, potential for highlighting surface imperfections, and tendency to show fingerprints more readily than flatter finishes.

Bottom Line: Ideal for projects demanding a bright, reflective finish, this spray excels on furniture, decorative items, and outdoor pieces. Choose this when you want maximum shine and durability. Just ensure proper surface prep, as gloss magnifies flaws. A top choice for glossy clear coating needs.

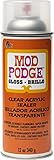

3. Mod Podge Spray Acrylic Sealer that is Specifically Formulated to Seal Craft Projects, Dries Crystal Clear is Non-Yellowing No-Run and Quick Drying, 12 ounce, Gloss

Overview: Mod Podge’s Spray Acrylic Sealer is a craft-room essential designed specifically for sealing artistic creations. This 12-ounce aerosol provides a crystal-clear, glossy finish that protects paper crafts, decoupage, and mixed-media projects. Unlike general-purpose sprays, it’s formulated to remain flexible and non-yellowing, preserving your artwork’s integrity over time.

What Makes It Stand Out: The non-yellowing formula is a game-changer for light-colored and white crafts that traditional sealers might discolor. Its no-run consistency prevents the dreaded drips that ruin delicate paper projects, while quick-drying properties allow rapid project completion. The trusted Mod Podge name brings 50 years of craft expertise to a convenient spray format.

Value for Money: At $10.49 ($0.87 per ounce), this premium-priced sealer costs significantly more than hardware-store alternatives. However, the craft-specific formulation justifies the expense for serious hobbyists. The specialized properties—non-yellowing, no-run, and safe for delicate materials—make it worth the investment for projects where standard clear sprays would fail.

Strengths and Weaknesses: Strengths include excellent performance on porous craft surfaces, easy cleanup with nozzle-clearing spray feature, and reliable non-yellowing protection. It’s made in the USA and safe for most craft applications. Weaknesses include higher cost, less durability for heavy-duty outdoor use, and potential incompatibility with some plastics compared to oil-based alternatives.

Bottom Line: This is the gold standard for craft sealing. While overkill for basic household projects, it’s indispensable for preserving precious artwork, scrapbooks, and delicate decoupage. The premium price delivers premium results where it matters most. Serious crafters should accept no substitute.

4. Krylon I00500A07 12-Ounce Triple Thick Clear Glaze Aerosol Spray,High-Gloss

Overview: Krylon’s Triple Thick Clear Glaze revolutionizes clear coating by delivering three coats’ thickness in a single application. This high-gloss aerosol creates a glass-like, permanent finish on polymer clay, bisque, plaster, and more. The 12-ounce can builds substantial depth quickly, making it ideal for craft projects requiring a substantial protective barrier.

What Makes It Stand Out: The triple-thick formula is uniquely suited for crafts needing a pronounced, dimensional finish. One application achieves what typically requires three separate coats, saving time and reducing the risk of dust contamination between layers. The extra high-gloss finish creates a jewelry-quality luster on decorative objects, while the non-firing glaze works perfectly for oven-bake clay projects.

Value for Money: At $6.47 ($0.54 per ounce), it’s slightly more expensive than standard Rust-Oleum clears but potentially more economical due to its triple-coverage claim. For crafters building thick protective layers, this eliminates purchasing multiple cans of thinner product. The time savings alone provide significant value for production crafters and hobbyists alike.

Strengths and Weaknesses: Strengths include rapid build-up of thick, durable coating, exceptional high-gloss shine, and specialized formulation for craft materials. It creates a professional, glass-like finish. Weaknesses include potential for runs if over-applied, limited suitability for large surface areas, and longer curing time due to thickness. The heavy build may obscure fine details on intricate pieces.

Bottom Line: This is a specialty tool for crafters needing maximum thickness and shine. It excels on jewelry, figurines, and decorative items where a glass-like dome effect is desired. Not for everyday sealing, but unbeatable for its specific purpose. Apply thinly to avoid runs and achieve the best results.

5. Rust-Oleum 334022 Painter’s Touch 2X Ultra Cover Spray Paint, 12 oz, Matte Clear

Overview: Rust-Oleum’s Painter’s Touch 2X Ultra Cover in Matte Clear offers the same versatile protection as its glossy counterparts with a completely flat, non-reflective finish. This oil-based spray works on wood, plastic, metal, masonry, and ceramic for both interior and exterior projects. The matte appearance hides surface flaws while providing robust, long-lasting protection.

What Makes It Stand Out: The zero-sheen finish is perfect for contemporary designs and projects where glare is undesirable. It effectively conceals scratches, dents, and imperfections that glossier finishes would highlight. The 2X coverage technology ensures efficient application, while the oil-based formula delivers the same durable, chip-resistant protection found in the gloss and semi-gloss versions.

Value for Money: At $6.19 ($0.52 per ounce), it matches the exceptional value of other Painter’s Touch clears. The 12 square foot coverage and durable formulation provide long-term protection without premium pricing. For projects requiring a flat finish, it eliminates the need to dull down glossy sprays, saving both product and effort.

Strengths and Weaknesses: Strengths include superior surface flaw concealment, excellent durability, fast 20-minute drying, and versatile substrate adhesion. The matte finish provides a modern, sophisticated appearance. Weaknesses include the strong odor common to oil-based sprays, reduced washability compared to gloss finishes, and potential for a chalky appearance if over-applied. Surface prep is still critical despite the forgiving finish.

Bottom Line: This is the go-to choice for projects demanding a flat, contemporary look. It performs beautifully on furniture, art pieces, and outdoor items where shine is unwanted. The same reliable Rust-Oleum quality at an unbeatable price point. Perfect for achieving a modern, non-reflective protective coating.

6. CERAKOTE® Platinum Rapid Ceramic Paint Sealant Spray - 14 oz Bottle - Maximum Gloss & Shine – Extremely Hydrophobic – Unmatched Slickness - Ceramic Spray Coating - 50 Wash Rating

Overview: The CERAKOTE Platinum Rapid Ceramic Paint Sealant represents a breakthrough in DIY automotive care, delivering professional-grade ceramic protection in a consumer-friendly spray format. This 14-ounce bottle promises mirror-like gloss and extreme water repellency through genuine ceramic technology, not just synthetic polymers. Designed for enthusiasts who demand showroom-quality results without professional installation costs, the sealant bonds to your vehicle’s clear coat to create a durable, slick barrier against environmental contaminants.

What Makes It Stand Out: The industry-leading 50-wash rating sets this product apart from typical spray waxes that last 2-4 weeks. CERAKOTE’s true ceramic formulation creates a molecular bond with paint, resulting in unparalleled slickness that must be felt to be believed. The extreme hydrophobicity causes water to bead and sheet off instantly, carrying dirt and grime with it. Application is remarkably simple: spray onto clean, dry panels and buff to a stunning shine—no complicated multi-stage process or curing time required.

Value for Money: At $19.69, this sealant occupies a sweet spot between $10 spray waxes and $500+ professional ceramic coatings. While significantly more expensive than traditional protectants, the extended longevity makes it cost-effective over time. Each application potentially lasts 6-12 months depending on conditions, translating to pennies per wash. For comparison, competing ceramic sprays with 20-wash ratings cost $15-25, making CERAKOTE’s 50-wash promise exceptional value.

Strengths and Weaknesses: Strengths include genuine ceramic protection, incredible gloss, superior water beading, ease of application, and impressive durability. The hydrophobic effect genuinely keeps cars cleaner between washes. Weaknesses involve the higher upfront cost, requirement for meticulous surface prep (any imperfections get locked in), and the 50-wash claim may be optimistic in harsh winter road salt conditions. The spray nozzle can occasionally dispense unevenly, requiring careful buffing.

Bottom Line: For DIY detailers seeking professional ceramic benefits without the professional price tag, CERAKOTE Platinum delivers exceptional performance. The genuine ceramic technology, combined with user-friendly application and remarkable longevity, justifies the premium price. While proper preparation is essential, the results rival coatings costing ten times more, making it a must-have for automotive enthusiasts.

7. Aleene’s Spray Finish 6oz Acrylic Sealer, 6 Ounce (Pack of 1), Clear-Matte

Overview: Aleene’s Spray Finish Acrylic Sealer brings the trusted quality of America’s favorite crafting adhesive brand to protective finishes. This 6-ounce matte sealer is engineered for hobbyists, crafters, and DIY households seeking a subtle, non-reflective protective coating. The fast-drying formula creates a durable barrier suitable for both indoor and outdoor projects, from decoupage and paper crafts to sealing painted garden ornaments. Its clear, non-yellowing composition ensures projects maintain their original appearance over time.

What Makes It Stand Out: The Aleene’s brand reputation carries generations of crafting trust, making this more than just another sealant. The subtle matte finish distinguishes it from glossy alternatives, providing professional-looking results without unwanted shine. Its versatility across materials—paper, wood, metal, and more—makes it a true multi-purpose workshop essential. The non-yellowing formula is particularly valuable for preserving light-colored projects and photographs, a common failure point in budget sealers.

Value for Money: Priced at $6.97 ($1.16 per ounce), this sealer offers excellent value for craft-scale projects. While larger bulk options exist for industrial use, the 6-ounce size is perfect for occasional crafters who don’t want product drying out between uses. Compared to specialized art sealers costing $2-4 per ounce, Aleene’s provides professional-grade non-yellowing protection at a hobbyist-friendly price point. The durability means projects won’t need frequent reapplication, saving money long-term.

Strengths and Weaknesses: Strengths include the trusted brand heritage, true matte finish, indoor/outdoor versatility, fast drying time, and reliable non-yellowing formula. It sprays evenly without blotching on most surfaces. Weaknesses are the small 6-ounce size limiting large project coverage, potential need for multiple thin coats on porous surfaces, and it’s not formulated for heavy-duty automotive or high-wear applications. The spray pattern can be narrow for broad surfaces.

Bottom Line: Aleene’s Matte Acrylic Sealer is an indispensable tool for crafters prioritizing quality and versatility. The subtle finish and non-yellowing protection make it ideal for preserving artwork, crafts, and DIY projects. While not suited for heavy industrial use, its performance-to-price ratio is outstanding for its intended audience. For hobbyists seeking reliable results without gloss, this delivers exceptional value.

8. Krylon K01305 Gallery Series Artist and Clear Coatings Aerosol, 11-Ounce, UV-Resistant Clear Gloss

Overview: Krylon’s Gallery Series UV-Resistant Clear Gloss elevates aerosol coatings to museum-quality standards. This 11-ounce aerosol provides artists and crafters with professional-grade UV protection in a convenient spray format. Engineered to shield artwork, photographs, and crafts from harmful light rays that cause fading, the non-yellowing formula maintains color integrity over time. The moisture-resistant barrier protects against humidity and accidental splashes, making it ideal for preserving valuable creations.

What Makes It Stand Out: The UV-resistant technology is the star feature, blocking damaging rays that degrade pigments and paper. Unlike standard clear coats that yellow within months, Krylon’s permanent, non-yellowing formula ensures archival-quality preservation. The Gallery Series designation signals professional-grade performance trusted by artists. The rapid drying time—mere minutes between coats—allows efficient project completion without dust contamination risks. The clear gloss finish enhances color vibrancy while providing robust protection.

Value for Money: At $10.99 ($1.00 per ounce), this coating offers professional preservation at a fraction of framing shop costs. While pricier than generic clear sprays, the UV protection justifies the premium for valuable artwork. A single can seals numerous medium-sized pieces, making it economical for active artists. The non-returnable policy reflects aerosol shipping regulations, not product quality, and the price remains competitive with other artist-grade fixatives.

Strengths and Weaknesses: Strengths include superior UV protection, guaranteed non-yellowing formula, rapid drying, moisture resistance, and professional-grade durability. It sprays smoothly without drips when applied correctly. Weaknesses are the non-returnable policy (understandable but inconvenient), potential over-spray on delicate papers, and the gloss finish may be too reflective for some art styles. It requires proper ventilation due to aerosol propellants.

Bottom Line: For artists serious about preserving their work, Krylon Gallery Series Clear Gloss is essential. The UV protection and non-yellowing formula provide peace of mind that standard sprays cannot match. While the gloss finish and aerosol format aren’t universal solutions, the archival-quality performance justifies the investment. This is professional preservation accessible to any creator.

9. Rust-Oleum 285093 Stops Rust Spray Paint, 12 Oz, Matte Clear

Overview: Rust-Oleum Stops Rust Matte Clear delivers industrial-strength protection in a budget-friendly aerosol. This 12-ounce can provides a weather and corrosion-resistant barrier for diverse surfaces including wood, metal, concrete, and masonry. The oil-based formula creates a durable, flat finish that minimizes surface imperfections while preventing rust formation. Designed for both exterior and interior applications, it excels at protecting outdoor furniture, railings, and tools from the elements while providing excellent abrasion, fade, and chip resistance.

What Makes It Stand Out: The legendary Rust-Oleum rust-prevention technology is the cornerstone feature, actively stopping oxidation rather than just covering it. The matte clear finish is unique among protective coatings, offering protection without unwanted shine or gloss. Its multi-surface versatility eliminates the need for separate primers and sealers on different materials. The oil-based composition penetrates deeply, creating a tenacious bond that withstands harsh mechanical wear and environmental exposure far better than water-based alternatives.

Value for Money: At $6.47 ($0.54 per ounce), this represents exceptional value—one of the most cost-effective protective clear coats available. The 12-ounce size covers up to 15 square feet, making it economical for large projects. While professional industrial coatings cost $8-15 per ounce, Rust-Oleum delivers comparable protection at a fraction of the price. The durability means less frequent reapplication, maximizing long-term savings.

Strengths and Weaknesses: Strengths include outstanding rust prevention, multi-surface compatibility, excellent durability, superior abrasion resistance, and unbeatable price. The flat finish effectively hides minor surface flaws. Weaknesses are the slower 2-4 hour dry time, strong oil-based odor requiring ventilation, and the finish may be too flat for some aesthetic preferences. Cleanup requires mineral spirits, and the oil-based formula has higher VOC content than modern water-based alternatives.

Bottom Line: For practical protection where durability trumps aesthetics, Rust-Oleum Stops Rust Matte Clear is unbeatable. The rust-prevention capability and multi-surface versatility make it ideal for tool maintenance, outdoor furniture, and industrial applications. While not suited for fine art or automotive show cars, its performance-to-price ratio is exceptional for functional protective needs. This is the workhorse of clear coatings.

10. Krylon K01309 Gallery Series Artist and Clear Coatings Aerosol, 11-Ounce, UV-Resistant Matte Spray Paint, 11 ounce, 11 Oz

Overview: Krylon’s Gallery Series UV-Resistant Matte Spray provides artists with the rare combination of archival UV protection and a non-reflective finish. This 11-ounce aerosol shields artwork, crafts, and photographs from harmful light rays while maintaining a sophisticated matte appearance. The non-yellowing, permanent coating ensures long-term color fidelity without the glossy sheen that can distract from subtle artistic details. Its moisture-resistant properties add another layer of preservation against environmental damage.

What Makes It Stand Out: The UV-resistant matte finish is remarkably uncommon—most protective sprays force a choice between UV protection (gloss) or matte finish (no UV protection). This product delivers both, making it invaluable for charcoal drawings, pastel work, and contemporary pieces where glare diminishes viewing experience. The Gallery Series pedigree guarantees museum-quality formulation. Fast drying allows multiple thin coats in a single session, building protection without runs or drips. The permanent, non-yellowing chemistry preserves delicate color palettes accurately.

Value for Money: At $14.83 ($1.35 per ounce), this commands a premium over the gloss version but justifies it for specific artistic needs. For artists working in light-sensitive media, this is far cheaper than professional framing with UV glass. The specialized matte UV formulation explains the higher price point compared to generic matte sprays. While not economical for large surfaces, its value lies in preserving irreplaceable artwork.

Strengths and Weaknesses: Strengths include unique UV protection with matte finish, non-yellowing formula, rapid drying, moisture resistance, and professional-grade durability. It sprays evenly without creating patchy areas. Weaknesses are the higher price per ounce, limited 11-ounce size for large projects, and the matte finish may slightly mute color vibrancy compared to gloss alternatives. Aerosol propellants require good ventilation.

Bottom Line: For artists requiring UV protection without gloss, this is a specialized gem. The combination of archival preservation and matte aesthetics fills a crucial niche. While pricier than standard options, it protects valuable artwork that generic sprays cannot. This is essential for serious artists working in media vulnerable to both light damage and reflective finishes.

What Are Paint Sealants and How Do Spray Formulations Differ?

Paint sealants represent the evolution of automotive surface protection, utilizing synthetic polymers rather than natural carnauba wax to create a durable shield against environmental contaminants. These formulations bond molecularly with your vehicle’s clear coat, forming a crystalline-like structure that resists UV degradation, chemical etching, and water spotting far more effectively than their organic counterparts.

The Science Behind Polymer-Based Protection

At the core of every spray sealant lies a complex blend of polymer resins—typically silicone dioxide (SiO2) or polytetrafluoroethylene (PTFE)—suspended in a carrier solution. When applied to properly prepared paint, these polymers cross-link and create a three-dimensional matrix that becomes semi-permanently affixed to the surface. This isn’t just sitting on top like wax; it’s forming a protective skin that maintains flexibility while providing rigid defense against contaminants. The spray format utilizes nano-scale particles that can be atomized into fine mists, allowing for thinner, more even application layers that cure faster and more uniformly than hand-applied pastes.

Spray Sealants vs Traditional Paste Wax

The fundamental difference extends beyond mere convenience. Paste waxes require heat from friction to melt and bond, often leaving uneven thickness that can create high spots or streaking. Spray sealants, conversely, use evaporative carriers that flash off within seconds, depositing a consistent monolayer of active ingredients. This means you’re less likely to experience product waste or application errors. Additionally, the cure time drops from hours to minutes, allowing you to layer protection or expose the vehicle to elements much sooner. The trade-off historically was durability, but modern spray formulations now rival or exceed the 3-6 month protection window of many paste waxes.

Understanding Synthetic vs Natural Ingredients

The philosophical divide between synthetic and natural protection mirrors the broader shift in automotive chemistry. Natural carnauba wax, derived from palm leaves, creates a warm, deep gloss but breaks down under UV exposure and washing chemicals within 4-8 weeks. Synthetic polymers are engineered for specific performance metrics—some prioritize extreme water repellency, others focus on chemical resistance or thermal stability. Spray sealants often incorporate hybrid technologies, blending SiO2 ceramics with polymer resins to capture the best of both worlds: the application ease of sprays with the longevity of ceramic coatings.

Key Benefits of Using Spray Paint Sealants

The automotive detailing community’s shift toward spray sealants isn’t merely a trend; it’s a response to measurable advantages that align with modern vehicle owner needs. These benefits extend far beyond the obvious time savings.

Time-Saving Application Process

A full paste wax application on a mid-size sedan can consume 45-90 minutes of careful, labor-intensive work. Spray sealants reduce this to 10-15 minutes once you’ve mastered the technique. The process eliminates the need for applicator pads, circular motions, and extensive cure time monitoring. You can literally spray, spread, and buff in sections, moving continuously around the vehicle without stopping. This efficiency doesn’t just save time—it reduces physical strain and makes maintaining protection realistic for busy schedules, encouraging more frequent application that ultimately keeps paint in better condition.

Versatility Across Vehicle Surfaces

Unlike paste waxes that can be problematic on textured plastics or rubber trim, most spray sealants are formulated for true multi-surface compatibility. The same product protecting your hood can typically be applied to glass for improved rain repellency, plastic trim for restored richness, and even wheels for easier cleaning. This universality simplifies your product arsenal and ensures consistent protection across all exterior surfaces. The thin film left by sprays won’t white-line textured plastics or create buildup in crevices, a common failure point of heavier paste applications.

Enhanced Durability Metrics

Modern spray sealants deliver protection periods that would have been unthinkable a decade ago. Quality formulations now provide 3-6 months of meaningful protection, with some ceramic-infused sprays pushing 8-12 months in optimal conditions. This durability stems from advanced polymer cross-linking that creates flexible yet resilient barriers. The spray format actually enhances this by ensuring uniform thickness—thin enough to prevent cracking from thermal cycling, yet dense enough to provide genuine protection. Regular maintenance with spray toppers can extend this indefinitely, creating a self-reinforcing protection system.

Cost-Effectiveness for Enthusiasts

When calculated per application, spray sealants often prove more economical than paste waxes. A 16-ounce bottle of concentrate can yield 20-30 applications on a standard vehicle, whereas a container of paste wax might provide 10-15 uses at double the price. Factor in the time saved—time that has value—and the economics become even more compelling. For professional detailers, this efficiency translates to higher throughput and profitability. For DIY enthusiasts, it means professional-grade protection without the professional-grade time commitment.

Essential Features to Evaluate Before Buying

Navigating the sea of spray sealants requires understanding which specifications genuinely impact performance versus which are marketing fluff. Focus your evaluation on these critical attributes.

Hydrophobic Properties and Water Behavior

The “water beading” effect is more than visual satisfaction—it’s a functional indicator of surface energy. Superior spray sealants create contact angles exceeding 110 degrees, causing water to form tall, tight beads that roll off at minimal angles. But beading isn’t the whole story. Sheeting behavior—how water flows off flat surfaces—prevents water spot formation more effectively than beading alone. Look for formulations that advertise both high contact angles and low sliding angles. Test videos showing water behavior on horizontal surfaces reveal more than promotional photos of perfectly round beads.

UV Inhibitor Concentration Levels

Clear coat failure begins with UV degradation breaking down the resin binder, leading to oxidation and color fading. Quality spray sealants incorporate UV absorbers and stabilizers that sacrificially absorb radiation before it penetrates to the paint. The concentration matters more than the presence alone. Products specifying “UV inhibitors” without detailing concentration percentages or protection factors may contain only token amounts. Professional-grade formulations often list their UV package explicitly, sometimes referencing benzotriazole or hindered amine light stabilizer (HALS) technologies that provide measurable protection.

Gloss Enhancement Capabilities

Not all gloss is created equal. Some sealants create a “sharp” gloss through optical clarity and surface leveling, while others produce a “deep” or “wet” look through refractive index manipulation. The best spray sealants achieve both by filling micro-imperfections while maintaining a high refractive index that amplifies paint clarity. Look for products that specify gloss enhancement through surface energy modification rather than just “shine.” The presence of gloss meters (GU readings) in technical documentation indicates serious formulation testing rather than subjective claims.

Chemical Resistance Ratings

Your sealant faces constant assault from bird droppings, bug splatter, tree sap, acid rain, and harsh wash chemicals. The chemical resistance of a spray sealant determines how long it maintains integrity under these conditions. Quality formulations specify pH tolerance ranges, typically resisting acids down to pH 2 and alkalis up to pH 12. Some advanced sprays incorporate chemical sacrificial layers that etch preferentially, protecting the underlying polymer matrix. Ask for chemical resistance data sheets or look for ISO testing references that validate these claims beyond anecdotal evidence.

Temperature Stability Parameters

Paint surfaces can exceed 180°F in summer sun, while winter temperatures can drop below freezing during application. A spray sealant’s glass transition temperature (Tg) determines its performance across this spectrum. Formulations with Tg values between -40°F and 200°F remain flexible without becoming tacky or brittle. Products specifying “thermal cycling resistance” have been tested through repeated temperature extremes without delamination. This is particularly crucial for dark-colored vehicles that absorb more infrared radiation and experience more dramatic thermal expansion and contraction.

Application Techniques for Professional Results

Even the finest spray sealant performs poorly without proper application methodology. The difference between amateur and professional results lies in technique, not product choice alone.

Surface Preparation Protocols

The foundation of lasting protection is surgically clean paint. Begin with a thorough wash using a pH-neutral shampoo, followed by chemical decontamination with iron removers and tar dissolvers. Mechanical decontamination using a clay bar or synthetic clay mitt removes bonded contaminants that washing misses. Finally, perform a panel wipe-down with isopropyl alcohol (IPA) solution or dedicated surface prep spray at 15-25% concentration. This eliminates polishing oils, fingerprints, and residue that prevent molecular bonding. Skipping any step compromises durability by up to 60%, as the sealant bonds to contaminants rather than clear coat.

Spraying Methods and Patterns

Hold the trigger 6-8 inches from the surface and use a sweeping motion that overlaps by 50%. Apply 2-3 light mists per panel rather than a single heavy application—this prevents pooling and ensures even distribution. Work in 2x2 foot sections on vertical panels and 3x3 foot sections on horizontal surfaces. The “less is more” philosophy is critical; excess product doesn’t increase protection but does increase buffing difficulty and streaking risk. In windy conditions, spray onto a microfiber towel first, then wipe onto the surface to prevent product loss and overspray onto glass or trim.

Buffing Strategies for Optimal Bonding

Use high-quality, edgeless microfiber towels with 300+ GSM (grams per square meter) for buffing. Fold the towel into quarters, creating eight clean faces. Use light, linear motions rather than circular buffing to minimize static charge buildup and micro-marring. The first pass should remove 80% of residue, while a second clean towel performs final leveling. Buffing too aggressively or too soon can lift uncured polymers, while waiting too long makes removal difficult. The sweet spot is typically when the product flashes (2-30 seconds depending on humidity) but hasn’t fully cured. Temperature and humidity dramatically affect this window—practice on a test panel to dial in timing.

Layering Considerations and Cure Times

Most spray sealants achieve maximum density with two properly applied layers. Apply the first layer, allow it to cure for 30-60 minutes, then apply the second. This isn’t about thickness but about achieving complete surface coverage and cross-link density. Some formulations are designed for “wet-on-wet” application where subsequent layers can be applied immediately, but these are exceptions. After final application, allow 4-6 hours of cure time before exposing to water or dew. Full chemical curing continues for 24-48 hours, during which the vehicle should avoid washing, rain, or garage condensation. Patience during curing determines real-world durability more than any other factor.

Common Mistakes That Compromise Performance

Understanding what not to do is often more valuable than knowing proper technique. These three errors account for 90% of spray sealant failures in consumer applications.

Over-application Issues

The mantra “more product equals more protection” is dangerously false with spray sealants. Excessive product creates thick films that cure unevenly, leaving high spots that appear as streaky or hazy patches. These thick sections are also more prone to cracking during thermal cycling and can attract dust due to incomplete curing. Over-application wastes product and increases removal difficulty exponentially. If you’re experiencing streaking that won’t buff out, you’re almost certainly using too much product per square foot. A 16-ounce bottle should provide 20+ applications on a standard vehicle—if you’re using more than an ounce per car, reevaluate your technique.

Environmental Factor Ignorance

Temperature and humidity aren’t just comfort factors—they’re chemical reaction parameters. Applying sealant in direct sunlight heats panels to 150°F+, causing carriers to evaporate instantly before polymers can level and bond. High humidity (above 70%) slows flash time, making removal difficult and streaky. Cold temperatures (below 50°F) prevent proper polymer cross-linking, resulting in soft, short-lived protection. Wind introduces airborne contaminants and causes uneven spray patterns. Ideal conditions are 65-75°F, 40-60% humidity, in shade with minimal wind. Checking the dew point is critical—if it’s within 5°F of ambient temperature, moisture will condense on panels during application.

Incompatible Product Stacking

Not all protection layers play nicely together. Applying a silicone-based spray sealant over a recently applied carnauba wax can cause beading and poor adhesion, as the wax’s oils interfere with polymer bonding. Conversely, some ceramic coatings require specific topper chemistries—using the wrong spray sealant can degrade the base coating’s performance. Always check manufacturer compatibility charts. When in doubt, strip previous protection completely with a panel prep spray or light polish. The general rule: synthetics over synthetics, but verify the specific polymer families. Acrylic polymers, SiO2 ceramics, and PTFE sealants each have different compatibility profiles that can make or break a multi-layer protection system.

Understanding Durability Expectations

Marketing departments love to promise “12 months of protection,” but real-world durability depends on numerous variables. Setting realistic expectations prevents disappointment and ensures proper maintenance scheduling.

Realistic Longevity Timelines

In controlled environments, premium spray sealants can indeed last 6-8 months. However, daily drivers facing sun, rain, automated car washes, and bird droppings typically see meaningful protection for 3-4 months. Garage-kept weekend cars might stretch this to 5-6 months. The key is understanding “meaningful protection”—the point at which water beading drops below 90 degrees contact angle and chemical resistance degrades significantly. Track performance monthly by observing water behavior and contamination release. When water stops sheeting and begins wetting the surface, it’s time to reapply, regardless of what the calendar says.

Factors That Accelerate Degradation

Certain conditions mercilessly attack sealant integrity. Parking outdoors in direct sunlight for 8+ hours daily can halve expected durability. Automated car washes with harsh detergents (pH 11-13) and abrasive brushes strip protection exponentially faster than hand washing. Bird droppings and bug splatter left for more than 24 hours create acidic micro-environments that etch through even robust sealants. Industrial fallout, railroad dust, and pollen contain metallic particles that embed and oxidize, compromising the polymer matrix. Road salt and magnesium chloride used for de-icing are particularly aggressive, requiring more frequent reapplication in winter climates.

Maintenance Washing Impact

Your washing technique directly impacts sealant longevity. Using pH-neutral shampoos preserves protection, while harsh detergents strip it. Two-bucket methods with grit guards prevent introducing swirl marks that compromise the sealant’s surface integrity. Wash frequency matters too—letting dirt and contamination bond for weeks creates more work and uses more aggressive cleaning that degrades protection. Weekly maintenance washes with sealant-safe soaps actually extend durability by preventing contamination buildup. Some shampoos contain trace amounts of compatible polymers that refresh protection with each wash, creating a symbiotic relationship between cleaning and protection.

Performance Metrics That Matter

Objective measurements separate marketing fiction from chemical fact. Understanding these metrics allows you to evaluate products like an engineer rather than a consumer.

Contact Angle Measurements Explained

Contact angle quantifies surface hydrophobicity—the angle at which a water droplet meets the surface. A contact angle above 90 degrees indicates hydrophobic behavior, but premium sealants achieve 110-120 degrees. This measurement matters because higher angles mean less water contact area, reducing spotting and contamination transfer. However, contact angle hysteresis (the difference between advancing and receding angles) is equally important. Low hysteresis means water slides off easily rather than sticking. The best sealants maintain high contact angles with low hysteresis, creating both beading and sheeting behavior that actively cleans the surface during rain.

Gloss Unit Readings

Gloss meters measure reflectance at specific angles (typically 20°, 60°, and 85°), providing objective gloss values. A quality spray sealant should increase gloss units by 15-25 points over bare clear coat on a 0-100 scale. The 20° reading indicates high-gloss performance, while the 60° measurement shows general reflectance. Be wary of products claiming “mirror finish” without supporting gloss data. True gloss enhancement comes from surface leveling and refractive index matching, not just oily slickness that temporarily masks imperfections. Professional detailers use gloss meters to verify application quality and track degradation over time.

Slickness and Contamination Resistance

Slickness isn’t just about the tactile feel—it directly correlates with contamination resistance. A surface with low surface energy (high slickness) prevents dirt, tar, and industrial fallout from bonding strongly. You can quantify this with friction coefficient measurements, but practical testing works too. Run your hand across the panel; if it glides smoothly without grabbing, the sealant is performing. More scientifically, wipe the surface with a microfiber towel—if contamination transfers to the towel with minimal pressure, the sealant is maintaining its slickness. This property typically degrades before water beading diminishes, making it an early warning indicator for reapplication needs.

Environmental and Safety Considerations

Responsible car care extends beyond vehicle appearance to personal and environmental safety. Modern sealants contain powerful chemistry that demands respect.

VOC Compliance and Regulations

Volatile Organic Compounds (VOCs) in spray sealants contribute to air pollution and pose health risks. California’s CARB standards and federal EPA regulations limit VOC content to 7-25% depending on product category. Professional-grade sealants often contain higher VOC levels for performance, requiring careful ventilation. Consumer products typically feature water-based carriers with VOCs below 10% for safety. Check product Safety Data Sheets (SDS) for specific VOC percentages and ensure compliance with local regulations. Some jurisdictions prohibit high-VOC product shipping or require special disposal methods for contaminated towels.

Respiratory Protection Requirements

Even “low-VOC” products contain airborne particulates during spraying that can irritate lungs. The polymer mist created by atomization is respirable and can cause sensitization over time. Always use a NIOSH-approved N95 or P100 respirator when applying spray sealants, especially in enclosed spaces like garages. Simple dust masks provide inadequate protection against chemical vapors and aerosolized polymers. Ensure adequate ventilation—use exhaust fans to achieve 6-10 air changes per hour in garage settings. If you can smell the product strongly, your protection is insufficient. Symptoms of overexposure include headaches, dizziness, and throat irritation that can develop into chronic sensitivity.

Eco-Friendly Formulation Options

The market now includes genuinely eco-conscious formulations using bio-based polymers and water carriers. These products sacrifice some durability—typically 2-3 months versus 4-6—but eliminate petrochemical solvents. Look for EPA Safer Choice certification or European Ecolabels that verify environmental claims. Some brands offer concentrate formulas that reduce packaging waste and shipping emissions. Proper disposal matters too: never wash contaminated towels in household drains, as polymers can pass through wastewater treatment. Instead, allow towels to dry completely, then dispose of them as solid waste or use professional laundry services that filter automotive chemicals.

Integration With Existing Protection Layers

Spray sealants rarely exist in isolation. Understanding how they interact with other protection products determines whether you’re building a robust system or creating a chemical train wreck.

Applying Over Ceramic Coatings

Ceramic coatings create a semi-permanent base layer, but they benefit from sacrificial spray sealant toppers that absorb environmental abuse. The key is chemistry matching: SiO2-based sprays bond best to SiO2 ceramics, while polymer-based sprays work better with polymer coatings. Apply spray sealants to ceramic coatings after the coating has fully cured (typically 7 days). Use extremely light applications—ceramic surfaces are so slick that excess product won’t bond and will simply streak. These toppers refresh hydrophobicity and add gloss while extending the underlying coating’s life by 30-50%. Some ceramic manufacturers produce dedicated “boosters” that are optimized for their specific coating chemistry.

Wax Layer Compatibility

The old advice “never mix synthetics with naturals” holds truth. Carnauba wax creates an oily, low-surface-energy layer that prevents polymer sealants from properly bonding to the clear coat. If you’ve recently waxed, remove it completely before applying spray sealant. Conversely, you can apply wax over a fully cured spray sealant for enhanced warmth and depth, though this somewhat negates the sealant’s durability advantage. The synthetic base provides protection while the wax adds aesthetic richness. This combination works best on show cars where appearance trumps longevity. For daily drivers, stick to synthetic-only layering to maximize durability and minimize maintenance.

Bare Paint Application Protocols

Applying sealant to freshly corrected paint requires special consideration. After polishing, paint surfaces are “hungry” and can absorb sealant unevenly, creating dark spots or patchy protection. Always use a panel prep spray or IPA wipe-down to remove polishing oils and reveal the true paint surface. Apply sealant in thinner layers than usual, as bare paint can grab polymers aggressively. The first layer may cure faster than expected due to surface energy differences. Some professionals apply a “primer” layer of very light sealant, allow it to flash for 10 seconds, then remove immediately. This conditions the surface for the actual protective layer applied moments later.

Storage and Shelf Life Best Practices

That spray sealant in your garage is a complex chemical soup with a finite lifespan. Proper storage ensures you get full value from your investment.

Temperature-Controlled Storage

Extreme temperatures degrade polymer stability. Storage above 90°F accelerates chemical separation and can cause premature cross-linking inside the bottle, rendering the product unusable. Freezing temperatures cause emulsion breakdown and permanent separation. The ideal storage range is 50-75°F in a dark, climate-controlled space. Never store spray sealants in uninsulated garages that experience temperature swings. If product has been exposed to temperature extremes, inspect for separation, color changes, or clumping before use. Shaking vigorously may temporarily re-emulsify separated products, but performance will be compromised.

Container Integrity Maintenance

Spray triggers and caps are failure points that allow air ingress and solvent evaporation. Always replace caps tightly after use. Store bottles upright to prevent product from contacting trigger mechanisms, which can clog or degrade seals. If a trigger becomes clogged, remove it and soak in warm water rather than using pins that damage the atomizer. Some enthusiasts transfer products to glass bottles with chemical-resistant sprayers for long-term storage, as plastic bottles can allow slow solvent permeation over time. Check bottles annually for cracks or stress fractures, especially if stored in areas with vibration.

Expiration Date Awareness

Most spray sealants have a shelf life of 2-3 years from manufacture when unopened. Once opened, use within 12-18 months for optimal performance. The clock starts ticking once oxygen and moisture can enter the bottle. Write the opening date on the label with a permanent marker. Products past expiration may still apply but will exhibit reduced durability, poor beading, or streaking during removal. Some manufacturers batch-code bottles allowing you to verify production dates before purchase—avoid products sitting on shelves for over a year. If a product changes consistency, develops an off-odor, or separates permanently, discard it regardless of date.

Troubleshooting Common Application Problems

Even experienced detailers encounter issues. Knowing how to diagnose and correct problems saves time and prevents paint damage.

Streaking and High-Spot Removal

Streaks appear as hazy lines where product cured before proper leveling. High spots are thicker areas that cure with a visible texture. Both indicate over-application or delayed buffing. To fix, mist a clean microfiber towel with quick detailer or panel prep spray and gently wipe the affected area using light pressure. The lubricant reactivates uncured polymers, allowing them to level. For stubborn high spots, use a finishing polish with light cutting ability on a foam pad—this removes the sealant layer entirely, requiring reapplication. Prevention is easier: work smaller sections and buff immediately after flashing.

Poor Beading Performance Fixes

If water stops beading within days of application, contamination is the likely culprit. Industrial fallout, soap residue, or incompatible products create low-surface-energy spots that prevent water from beading. Perform a decontamination wash with iron remover and clay treatment, then reapply sealant to affected panels. If beading was never strong, the issue is likely surface preparation—polishing oils or silicone residues prevented bonding. In this case, strip completely and restart the process. Some sealants require a “break-in period” of 24-48 hours to achieve full hydrophobicity; don’t judge performance immediately after application.

Adhesion Failure Diagnosis

When sealant peels or wipes off completely during washing, adhesion has failed. This typically stems from three causes: inadequate surface prep, application in poor conditions, or product incompatibility. Test adhesion using the “tape test”—apply painter’s tape to the sealed surface and rip it off quickly. If sealant transfers to the tape, adhesion is compromised. The only solution is complete removal using a panel prep spray or light polish, followed by meticulous reapplication following ideal environmental protocols. Check that your wash shampoo doesn’t contain waxes or sealants that interfere with bonding.

Seasonal Application Strategies

Environmental conditions vary dramatically by season, requiring adaptive techniques for consistent results.

Summer Heat Application Challenges

High ambient temperatures cause carriers to flash instantaneously, preventing proper leveling. Work in early morning or evening when panels are cool to the touch. Keep product and towels in a cooler to prevent heat soaking. Mist panels with water before application to lower surface temperature, then dry and apply sealant immediately. Work in 1x1 foot sections to ensure you can buff before flashing occurs. Some professionals use ice packs wrapped in microfiber to cool panels section-by-section during extreme heat. Never apply sealant to panels above 90°F—durability drops by 50% or more.

Winter Cold Weather Bonding

Cold temperatures slow polymer cross-linking to a crawl. Application below 50°F results in soft, easily removed protection that never fully cures. If you must apply in cold weather, heat the garage to 65°F for 24 hours before and after application. Use a space heater to warm individual panels to at least 60°F before applying. Extend cure times dramatically—wait 12-24 hours before exposing to moisture. Some formulations include catalysts that accelerate curing in cold weather; these are worth seeking for northern climates. Never apply sealant when temperatures will drop below freezing within 6 hours, as ice crystal formation disrupts polymer structure.

Humidity and Dew Point Factors

High humidity extends flash time and can cause blush—a milky haze from moisture trapped in the curing film. Monitor dew point religiously; if it’s within 10°F of ambient temperature, moisture will condense on panels. Use a hygrometer to verify humidity levels below 60% before starting. In humid climates, work in air-conditioned spaces or use dehumidifiers. If blush occurs, mist the area with panel prep spray and rebuff immediately. Some sealants include anti-blush additives that tolerate higher humidity, but these typically sacrifice some gloss. The dew point rule is absolute—if condensation is forming on your cold beverage, it’s forming on your car.

Professional vs DIY User Considerations

The gap between professional and amateur results narrows with quality spray sealants, but important distinctions remain.

Skill Level Requirements

Spray sealants democratize paint protection, requiring minimal skill compared to ceramic coatings or even paste waxes. The learning curve involves mastering flash time recognition and proper buffing pressure—achievable within 2-3 applications. Unlike coatings that demand flawless technique to prevent high spots, sprays are forgiving. However, understanding surface preparation and environmental control still requires study. DIY users can achieve 90% of professional quality by following manufacturer instructions meticulously. The remaining 10% comes from experience-based judgment calls about layer thickness and cure timing that only practice develops.

Equipment Investment Needs

The barrier to entry is remarkably low. Essentials include: 4-6 high-quality microfiber towels (300+ GSM), a NIOSH-approved respirator, a spray trigger bottle, and proper lighting. Professionals add hygrometers, infrared thermometers for panel temperature monitoring, and paint thickness gauges to avoid polishing through clear coat. For DIY users, the towel quality is non-negotiable—cheap towels scratch paint and shed lint that interferes with bonding. Invest $30-40 in premium towels before buying expensive sealant. A $15 respirator protects your health, and a $10 spray bottle with adjustable nozzle provides better atomization than most product triggers.

Time Commitment Differences

A professional can seal a vehicle in 15 minutes, having mastered the rhythm of spray-spread-buff sequences. DIY users should budget 30-45 minutes for the first few applications, decreasing to 20-30 minutes with experience. The real time investment is in preparation—proper washing, decontamination, and panel prep add 1-2 hours. Professionals streamline this with pressure washers, foam cannons, and efficient workflows. DIY users should view preparation as separate from application; don’t try to wash and seal in the same session. Splitting these tasks allows proper drying time and prevents fatigue-induced mistakes during the critical sealing step.

Frequently Asked Questions

How often should I apply spray paint sealant to maintain optimal protection?

For daily drivers exposed to sun and elements, reapply every 3-4 months or when water beading noticeably declines. Garage-kept weekend cars can stretch to 5-6 months. Track vehicles exposed to track debris and frequent washing may need monthly touch-ups. The key is observing performance rather than following a calendar—when water stops sheeting and begins wetting the surface, protection has diminished.

Can I use spray sealant on a car that hasn’t been polished or corrected?

Absolutely, and this is where spray sealants shine for everyday car owners. While polishing enhances results by removing defects, sealants bond effectively to any properly cleaned clear coat. The protection benefits—UV resistance, chemical defense, and easier washing—apply regardless of paint perfection. In fact, sealants prevent correction needs by protecting factory finishes from deterioration. Just ensure thorough decontamination; polishing oils aren’t present, but road grime and contamination must be removed.

Will spray sealant damage my car’s plastic trim or rubber seals?

Quality modern spray sealants are trim-safe when applied correctly. The issue isn’t chemical damage but aesthetic—excess product can dry as white residue in textured plastic. Prevent this by masking trim with tape or wiping it immediately with a damp towel if overspray occurs. Some sealants contain ingredients that actually restore faded trim. Always check manufacturer specifications for “trim safe” claims, and test on an inconspicuous area first. Rubber seals are generally unaffected, but avoid direct saturation.

How do I know if my spray sealant has gone bad or expired?

Signs of degradation include: permanent separation that won’t remix after shaking, color changes from clear to yellow or cloudy, clumping or stringy consistency, and off-odors. Perform a test application on glass—if it doesn’t bead water after curing, the polymers have broken down. Most sealants last 2-3 years unopened, 12-18 months after opening. When in doubt, replace it; degraded sealant can bond poorly and become difficult to remove.

Can I layer different brands of spray sealants for increased protection?

This is risky without understanding the chemistry. Different polymer families can interfere with each other’s cross-linking, creating a gummy or easily removed layer. Stick to one brand’s ecosystem, or verify compatibility through manufacturer technical support. If you must experiment, apply the more durable product first, allow full cure (24-48 hours), then apply the second brand very thinly as a topper. Test on a small area first. The safest approach is using a single product designed for layering.

What’s the difference between a spray sealant and a ceramic spray coating?

The lines have blurred, but generally: spray sealants use polymer resins (acrylics, PTFE) while ceramic sprays contain SiO2 (silicon dioxide) in suspension. True ceramic sprays create harder, more durable layers (6-12 months) but can be trickier to apply without streaking. Polymer sprays offer easier application and better gloss but typically last 3-6 months. Many products now blend both technologies. For practical purposes, think of ceramic sprays as premium, longer-lasting options requiring more careful technique.

How long after applying spray sealant can I wash my car?

Minimum 4-6 hours before any water contact, but 24 hours is ideal for full chemical curing. If dew or unexpected rain occurs within 4 hours, you may see spots or reduced durability. After the initial cure period, use pH-neutral shampoo for the first month—harsh chemicals can disrupt final cross-linking. The sealant continues hardening for 7 days; treat it gently during this period. If you must wash sooner, use a rinseless wash method with minimal pressure and no agitation.

Do I need to remove old wax before applying spray sealant?

Yes, absolutely. Wax creates a sacrificial layer that prevents sealant polymers from bonding to clear coat. Remove it using a panel prep spray or IPA wipe-down (15-25% solution). For heavily waxed surfaces, you may need a light polishing pass to ensure complete removal. The “sealant over wax” approach yields protection that lasts only weeks rather than months, as the sealant bonds weakly to the wax which itself is degrading. Take the time to strip properly—it’s the difference between amateur and professional results.

Can spray sealant be applied to wheels and glass?

Most quality spray sealants are multi-surface safe and perform excellently on wheels, making brake dust and road grime much easier to clean. They provide 2-3 months of protection on wheels due to extreme heat and chemical exposure. On glass, they create water-repellent properties similar to rain repellents, but durability is limited to 4-6 weeks due to wiper abrasion. Some formulations specifically optimize for glass with harder polymers. Always verify “safe for wheels” claims, as brake dust can be corrosive. For windshields, dedicated glass coatings outperform general sealants.

Why does my spray sealant seem to last longer on some panels than others?

This is normal and expected. Horizontal panels (hood, roof, trunk) receive maximum UV exposure and environmental contamination, degrading 30-50% faster than vertical panels. Dark colors absorb more heat, accelerating polymer breakdown. Areas near heat sources (engine bay, exhaust) experience thermal cycling that stresses the sealant. Lower panels face more road grime and salt. This variation is why maintenance toppers are valuable—spot-treat horizontal surfaces every 6-8 weeks while full reapplication occurs every 3-4 months. Track performance panel-by-panel rather than expecting uniform degradation across the vehicle.